Introduction

Twins cladding roll forming machine is a multifunctional machine with high efficiency and creativity that has gained a very wide range of applications in the construction industry. The roll forming machine is specially designed for the manufacture of Twins Cladding insulated roof sheets.

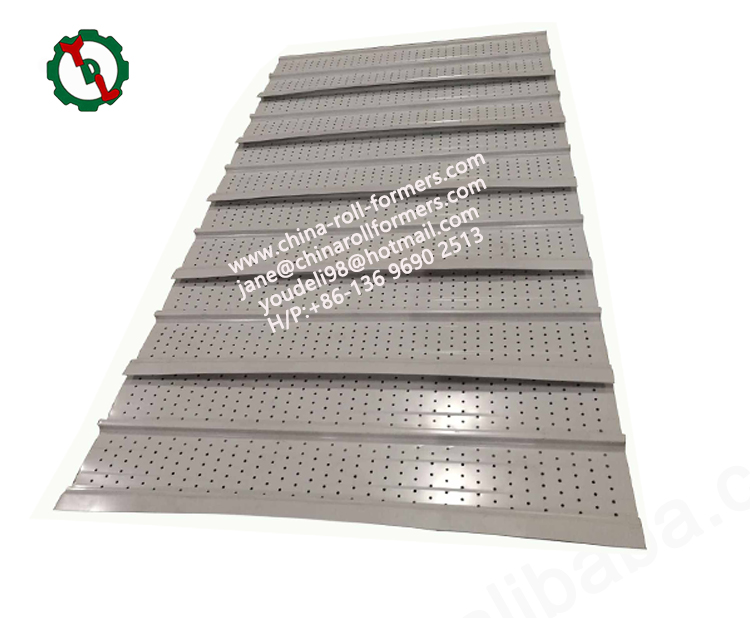

The main principle is that by creating an air gap between the two claddings, these panels obtain their well-known insulating qualities. This machine is ideal for the construction of industrial, commercial, and residential structures where adequate insulation is required to handle changing weather conditions.

Manufacturing Steps of Twins Cladding Roll Forming Machine

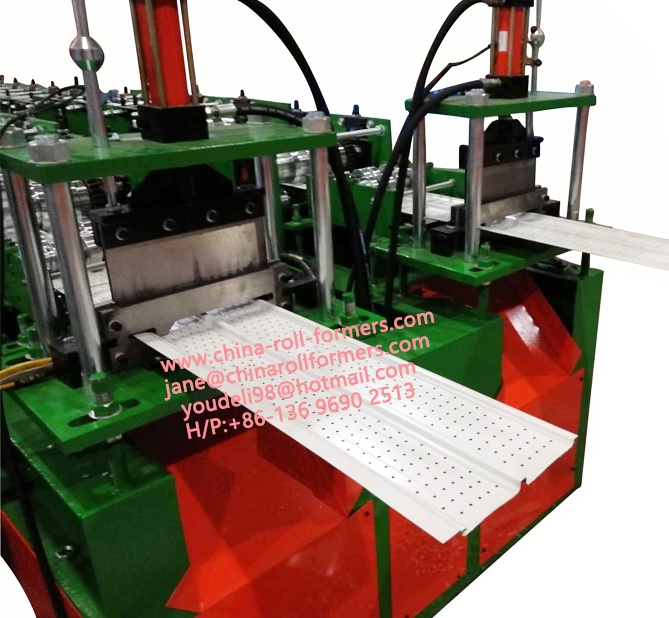

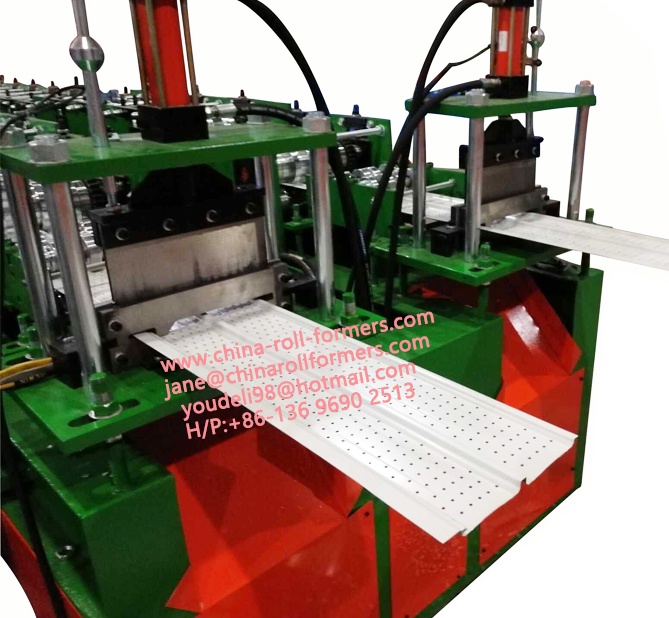

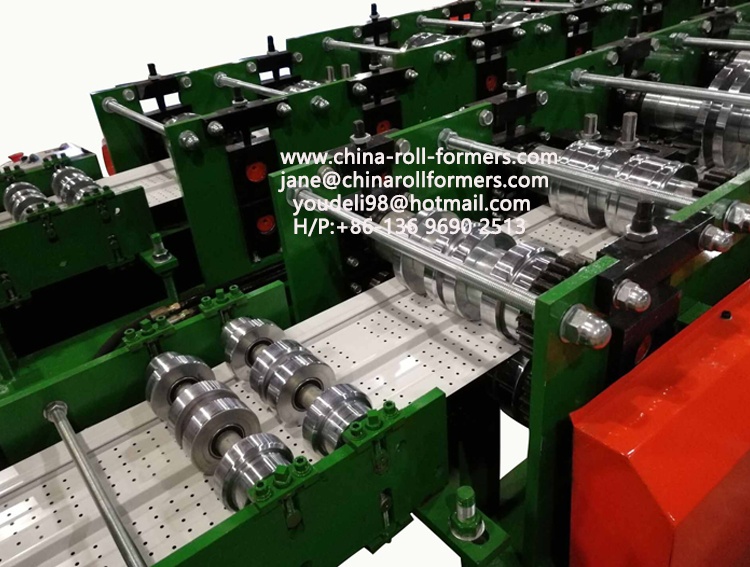

- Trim the metal sheet to the necessary width and length. The sheet metal is fed into a roll forming machine, which uses multiple rollers to form the sheet into the desired shape.

- Operators can quickly change the adjustability of these rollers to alter the shape of the finished product.

- After the metal sheet is formed, the machine cuts it to the desired length using a flying saw.

- Finished products are stacked and stored.

Twins Cladding Roll Forming Machine advantage

1. The Twins Cladding Roll Forming Machine does not require separate insulation panels (often installed on single-ply roof systems).

2. Twins Cladding is rolled together, reducing the overall weight of the roof system and resulting in significant cost savings.

3. The Twins Cladding covering further increases the strength and longevity of the roof system, making it ideal for locations with severe climates.

4. For quickly and efficiently manufacturing roof panels, the machine is much faster than conventional production techniques and can produce cladding up to 30 meters per minute.

5. The roll forming process also ensures the homogeneity of the product, resulting in a better quality and more reliable end product.

6. They can be modified to meet specific customer needs and can be used to manufacture roof panels of various sizes and forms.

7. At Youdeli, our company manufactures twins Cladding Roll Forming Machines that are flexible and efficient tools that are changing the construction industry. It is frequently used by builders and construction firms because of its ability to quickly produce high-quality double cladding while maintaining consistency and flexibility in the result. The use of this equipment makes it possible to produce attractive, long-lasting roofing systems that offer good insulation and are resistant to all weather conditions.

About machinery

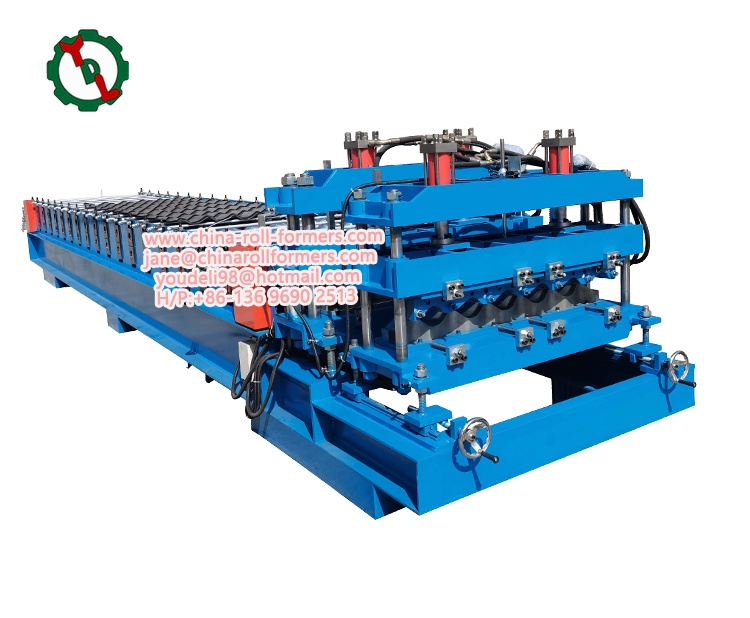

Two distinct types of roll forming machines play a pivotal role in the fabrication of cladding panels: double cladding roll forming machines and twin cladding roll forming machines. These cladding panels, produced at high speeds, find extensive use in construction projects.

In the case of the twins cladding roll forming machine, the process involves the concurrent rolling of metal sheets by two sets of rollers to craft the cladding panels. This method ensures exceptional precision and accuracy, as roller adjustments are not required during production. A control panel on the machine allows users to customize the speed and tension of the sheets.

Conversely, the twin siding roll forming machine is designed to produce two distinct types of cladding panels simultaneously. Similar to its counterpart, it offers the flexibility to adjust sheet speed and tension via a control panel.

Both the twin cladding roll forming machine and the double cladding roll forming machine can manufacture cladding panels with varying thicknesses and profiles. These machines are highly efficient and can produce a substantial quantity of cladding panels swiftly.

The construction sector extensively utilizes the cladding panels manufactured by these machines. These panels serve various purposes, including walls, roofs, and both exterior and interior building cladding.

To ensure the quality of the cladding panels produced by these machines, high-quality materials like galvanized steel or aluminum are essential. Additionally, meticulous cleaning and drying of the metal sheets used in the production process are imperative to prevent any imperfections in the final product.

In summary, the construction industry relies on two types of roll forming machines, namely the double cladding roll forming machine and the twin cladding roll forming machine, to efficiently produce cladding panels. These panels are integral to contemporary construction projects and contribute to the development of modern, energy-efficient structures.

| Model NO. | YX14-228 |

| Size | 7500*2000*1200mm |

| Weight | 6000KGS |

| Voltage | 220V/60HZ/3PH |

| Motor Power | 7.5KW |

| Hydraulic Power | 5.5KW |

| Forming Steps | 18steps |

| Forming Speed | 0-18m/min |

| Height of Colorclad Panel | 14mm |

| Effective Width | 228mm |

| Feeding Material Width | 0.3-0.6mm |

| Straightness | 2mm/m |

| Cutting Length Tolerance | +1.0mm,+2.0mm |

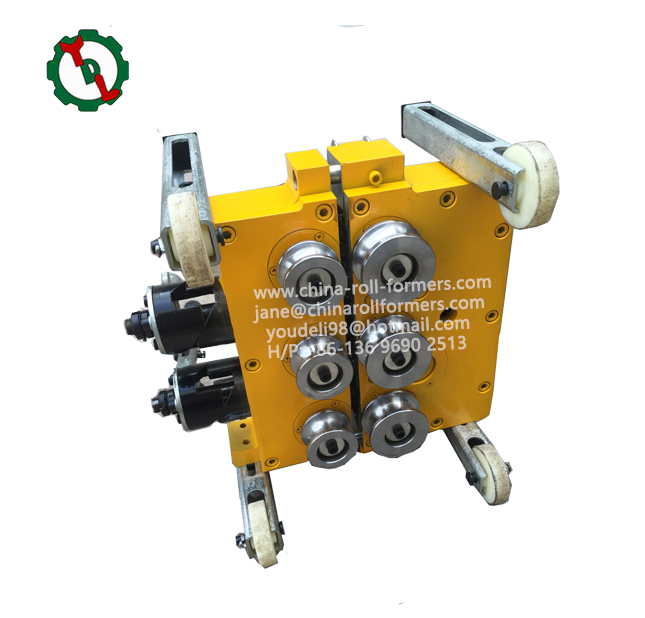

| Roller Material | High grade 45# forged steel, Plated hard chrome and polished all the rollers |

| Material of shaft | High grade 45# forged steel |

OUR SERVICES

1. Installationandtraining:

A. If buyers visit our factory and check the machine, we will teach you how to install and use the machine and also train your workers/technicians face to face.

B. Without visiting, we will send you a user manual and video to teach you how to install and operate.

C. If the buyer needs our technician to go to your local factory, please arrange board and lodging and

other necessary things.

2. after service

A. One-year guarantee for the whole machine

B. 24-hour technical support by email or telephone call.

C. If there is any problem found with the machine, we will repair it for free in one year.

OUR CUSTOMERS EXHIBITION