I. Introduction to C Channel Making Machine

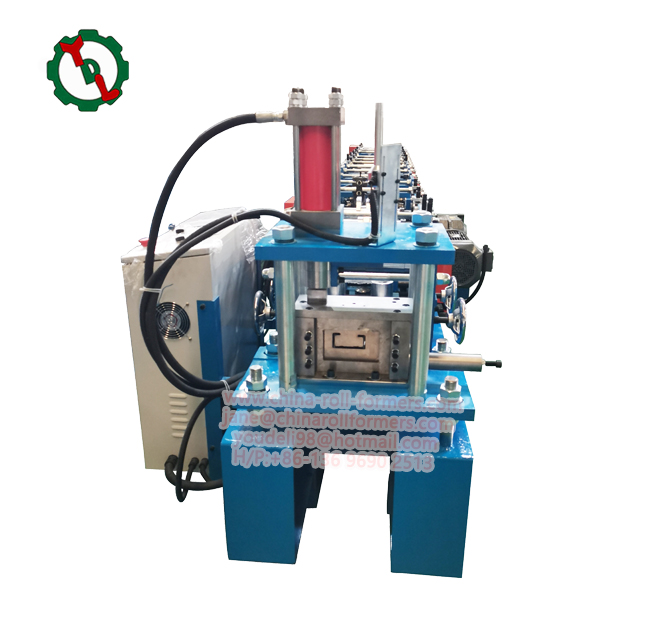

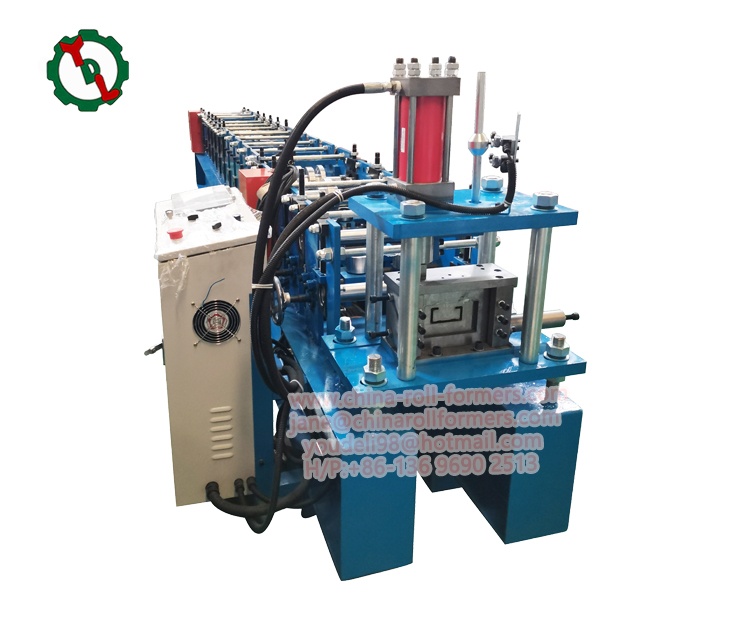

C channel making machine is a special mechanical equipment used to manufacture C channel steel. These C channels are widely used in construction, industry, and other fields because of their superior strength, durability, and flexibility. Fabrication equipment shapes metal sheets or coils into the exact shape and dimensions required by the user by passing the coil through the cold forming process. In this cold roll forming process, the metal material is passed through multiple rollers at room temperature and progressively formed into the correct contour. By adjusting these rollers, the size and shape of the channel can be customized according to specific needs. It is worth noting that “cold” flow forming means that the entire process is carried out at room temperature without heating the metallic material.

II. Cold Roll Forming Process for C Channels

The C Channel Making Machine is a very flexible machine that can be customized according to the needs of customers. It is capable of handling a wide range of thicknesses and widths of steel to create C-channels ranging in length from a few inches to a few feet. In addition, this machine can also be used to produce other profiles, such as U-shaped channels, Z-shaped channels, etc. Thanks to the highly automated mode of operation, it is able to produce finished products quickly and efficiently. Each roll runs synchronously and automatically cuts at predetermined intervals. By using the built-in special software, the machine can be precisely configured to meet all the necessary criteria.

III. Efficiency and Precision in C Channel Production

The C Channel Making Machine is an efficient and precise piece of equipment that is essential for the production of C-channels for various applications. With the help of modern engineering and programming techniques, this machine is able to precisely meet customer needs and produce precise and high-quality channel steel profiles that can be widely used in different fields. is a special mechanical equipment used to manufacture C-shaped channel steel.

These C Channel Making are widely used in construction, industry, and other fields because of their superior strength, durability, and flexibility. Fabrication equipment shapes metal sheets or coils into the exact shape and dimensions required by the user by passing the coil through the cold forming process. In this cold roll forming process, the metal material is passed through multiple rollers at room temperature and progressively formed into the correct contour. By adjusting these rollers, the size and shape of the channel can be customized according to specific needs. It is worth noting that “cold” flow forming means that the entire process is carried out at room temperature without heating the metallic material.

IV. Customization and Versatility of C Channel Making Machine

The C Channel Making Machine is a very flexible machine that can be customized according to the needs of customers. It is capable of handling a wide range of thicknesses and widths of steel to create C-channels ranging in length from a few inches to a few feet. In addition, this machine can also be used to produce other profiles, such as U-shaped channels, Z-shaped channels, etc. Thanks to the highly automated mode of operation, it is able to produce finished products quickly and efficiently. Each roll runs synchronously and automatically cuts at predetermined intervals. By using the built-in special software, the machine can be precisely configured to meet all the necessary criteria.

The C Channel Making Machine is an efficient and precise piece of equipment that is essential for the production of C Channel Making for various applications. With the help of modern engineering and programming techniques, this machine is able to precisely meet customer needs and produce precise and high-quality channel steel profiles that can be widely used in different fields.

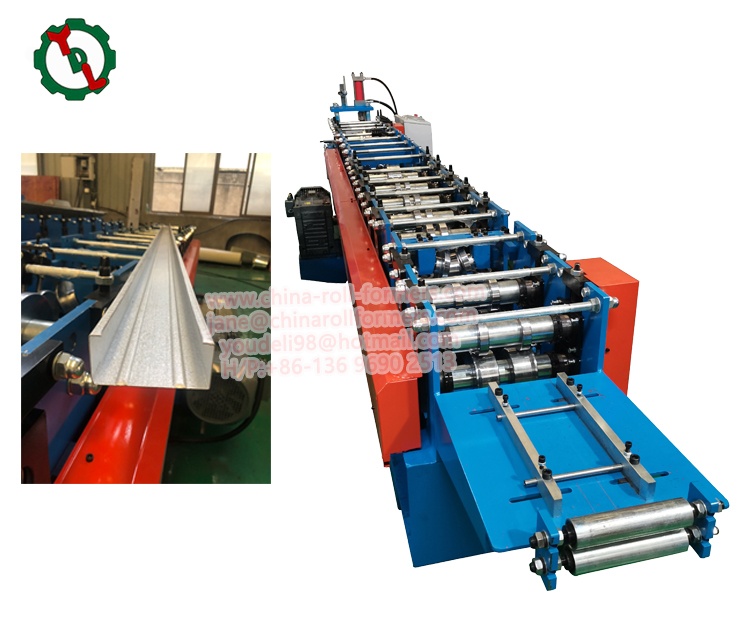

Parameter

- Model NO C32.5×35.5-75

- Size 5900*1450*1300mm

- Weight 3000KGS

- Voltage 415V/50HZ,3PH/ or as Request

- Motor Power 7.5KW

- Hydraulic Power 2.2KW

- Thickness 0.75-1.2mm

- Forming Steps 14steps

- Working Speed 0-18m/min

- Lip of C Purlin 8-15mm

- Height of C Section 32.5mm, 35.5mm

- Width of C Section 75mm

- Tolerance for cutting, forming ±2.0mm

- Material GI PPGI Aluminum

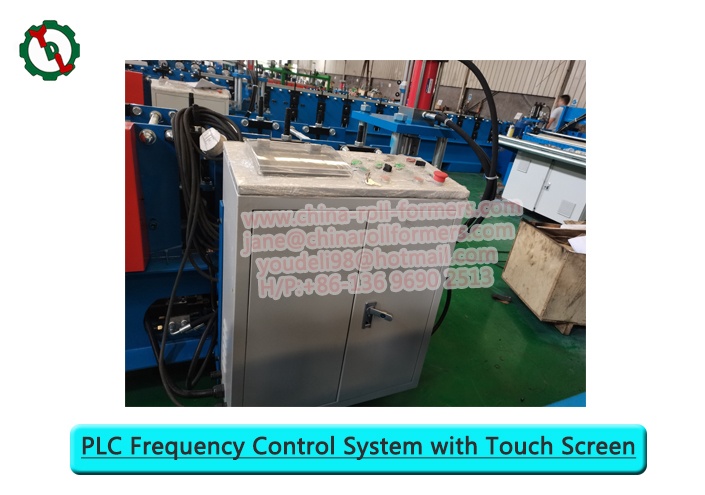

- PLC Program Control System Original Taiwan Delta / Siemens / Schneider

- After-Sale-Service Online 24hours/Field Support

- Service Provide Engineer to Install The Machines

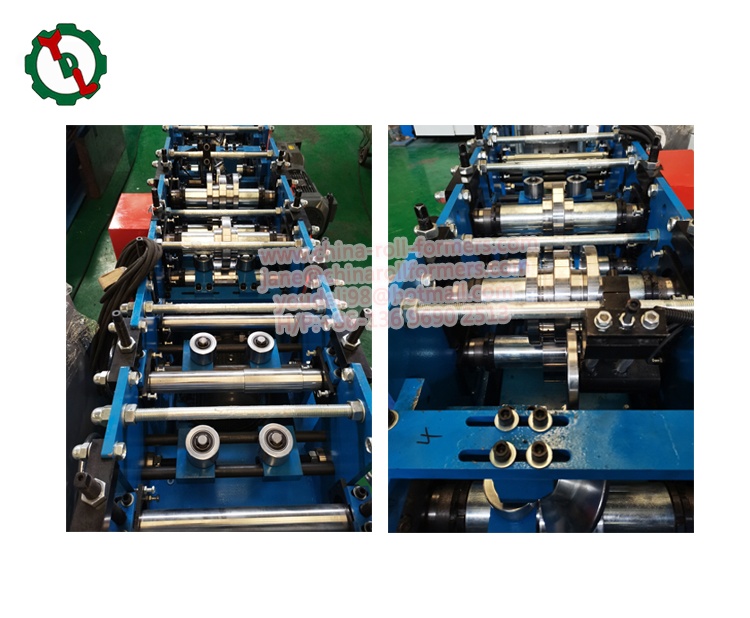

- Roller Material High grade 45# forged steel, Plated hard chrome

and polished all the rollers - Material of shaft High grade 45# forged steel

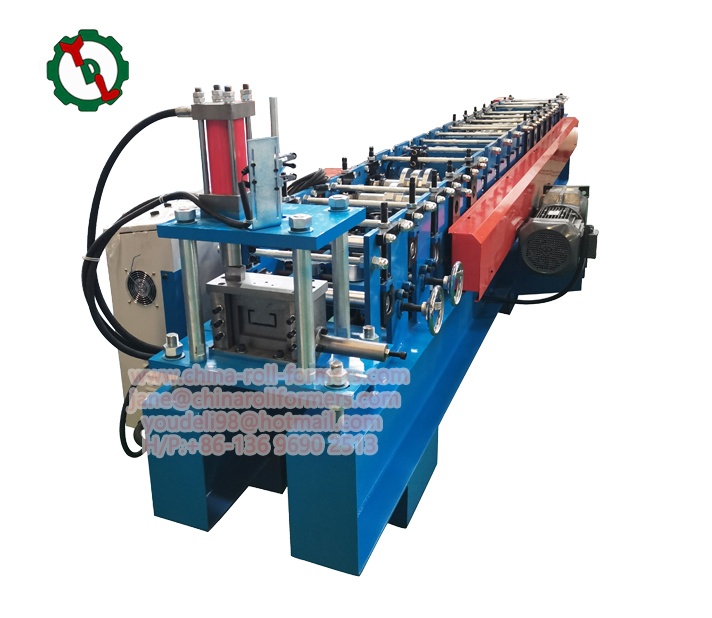

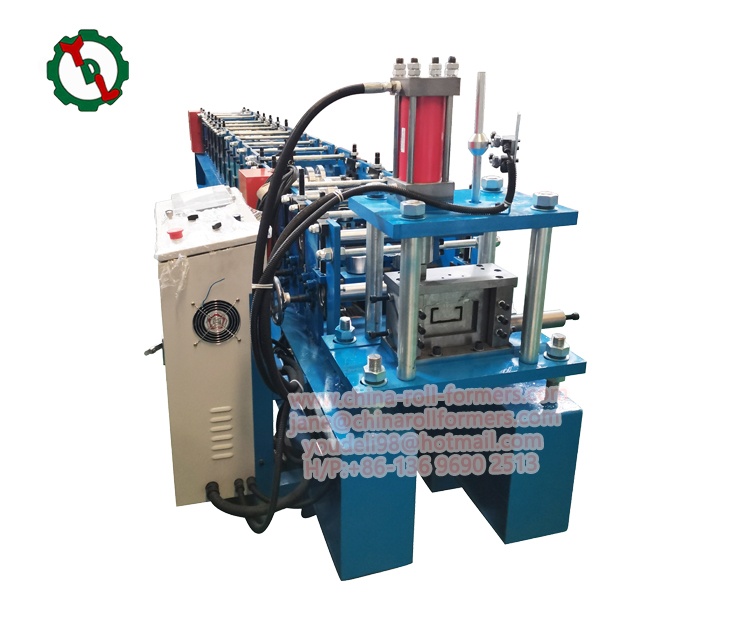

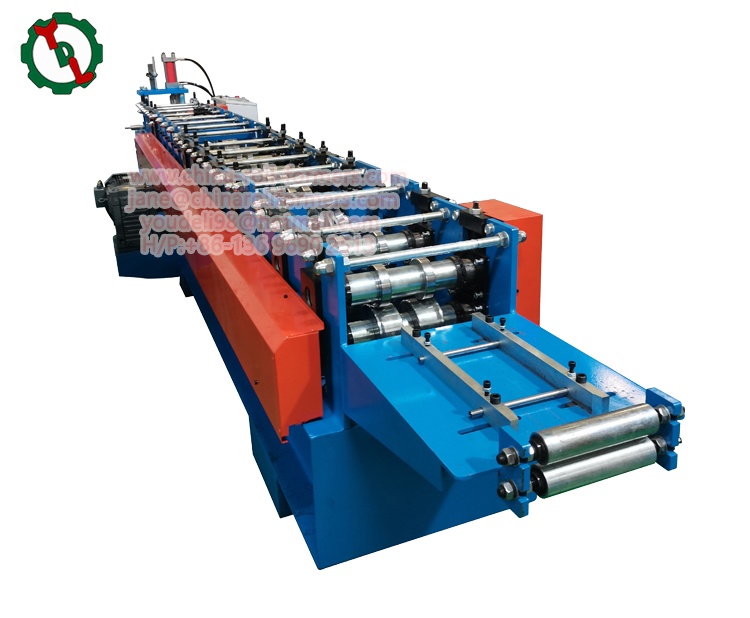

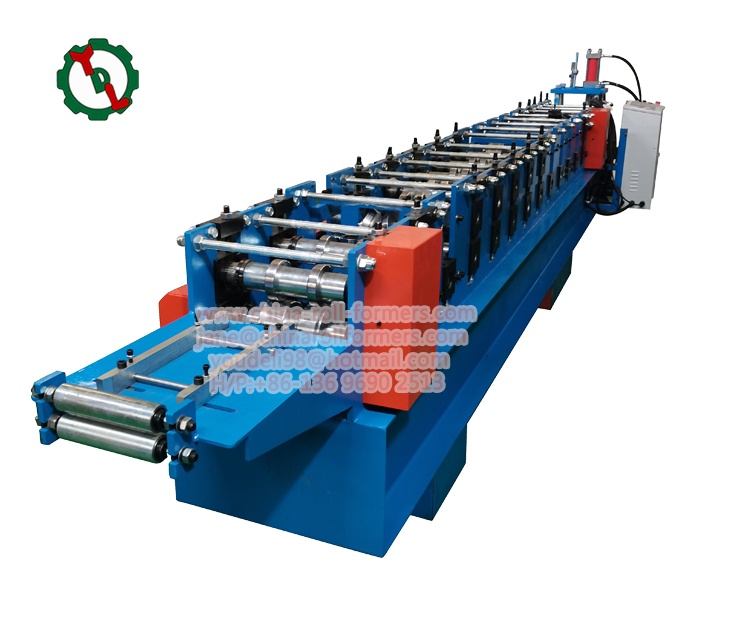

PRODUCT DISPLAY

Why Choose Us?

It is crucial to pick the best partner for your business in today’s world of rapid change and fierce competition. Here are some justifications for picking us:

- Expertise: We are a group of seasoned specialists committed to offering our customers specialized solutions. We have the expertise and knowledge required to support you in achieving your objectives.

- Client-centred approach: We are aware that every client is unique. Because of this, we take the time to carefully consider your demands and offer specialized services that are tailored to your particular needs. Our primary goal is always to meet or beat your expectations with our work.

- New Solutions: To provide you with new solutions that give you a competitive edge in your sector, we stay up with the most recent technological advancements and market trends. Our solutions are made to fit your particular requirements and are intended to assist you in achieving your company goals.

- Contented Customers: The happiness of our customers is the foundation of our success. We have a lengthy record of happy customers who choose us due to our dedication to quality and our capacity for producing outcomes.

- Value for Money: We recognize how crucial it is to receive value for your money. Because of this, we provide our services at fair prices without sacrificing their caliber.