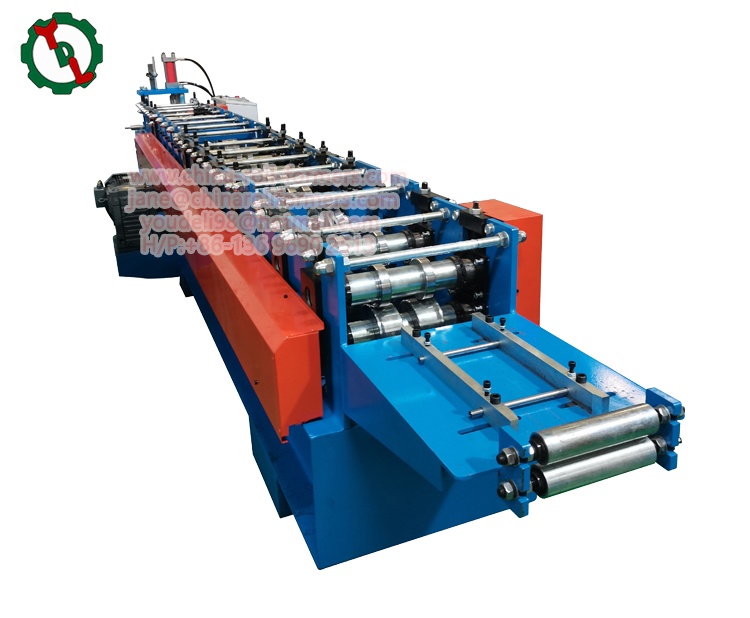

The roofing business has undergone a transformation thanks to the Automatic Portable Standing Seamless Panel Sheet Metal Mobile Roll Forming Machine Roof Seamer. It is now more simpler, quicker, and possible to produce standing seam roofs with unmatched perfection thanks to this equipment.

The period when roofing required a lot of time and labor is long behind. Roofing contractors can now produce stunning, robust, and stable standing seam roofs in a fraction of the time it would take with conventional roofing procedures thanks to the Automatic Portable Standing Seamless Panel Sheet Metal Mobile Roll Forming Machine Roof Seamer.

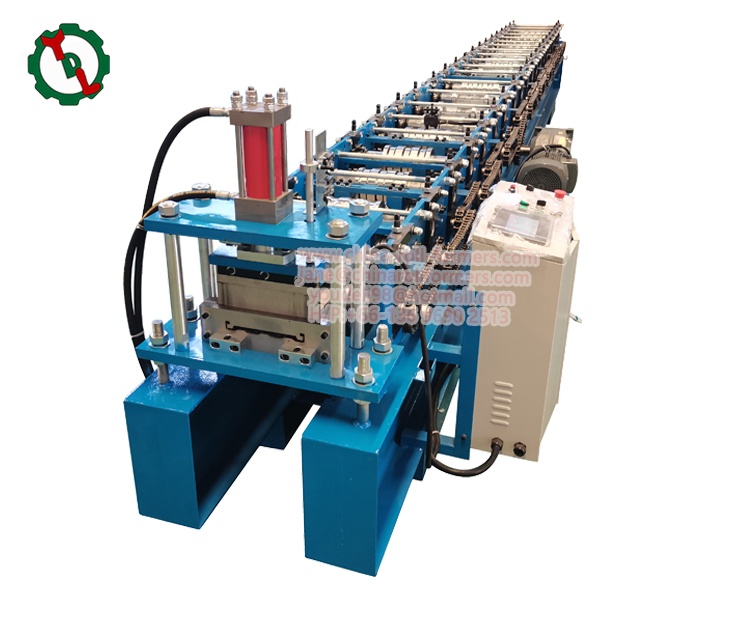

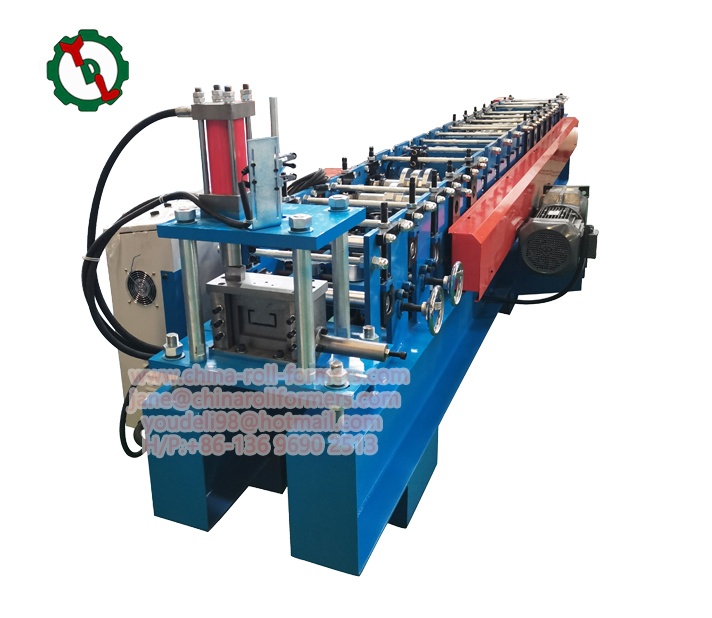

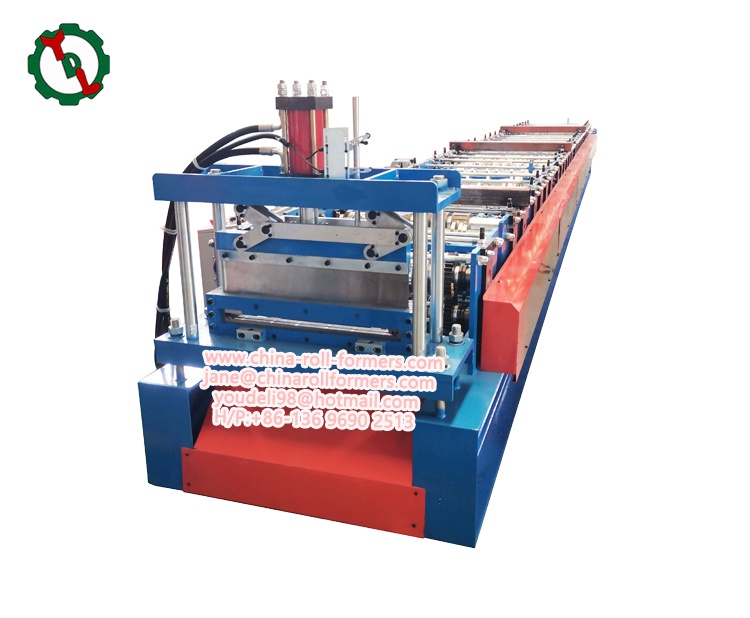

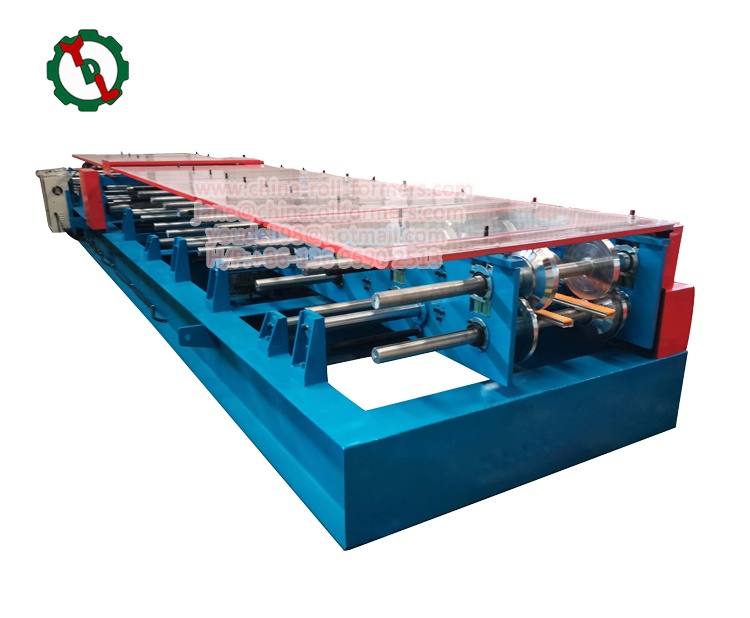

Standing seam panels can be produced on-site using the machine, doing away with the necessity for pre-fabrication and installation. A standing seam profile is created, the metal sheets are cut to exact lengths, and the panels are then sewn together without the use of joints or fasteners.

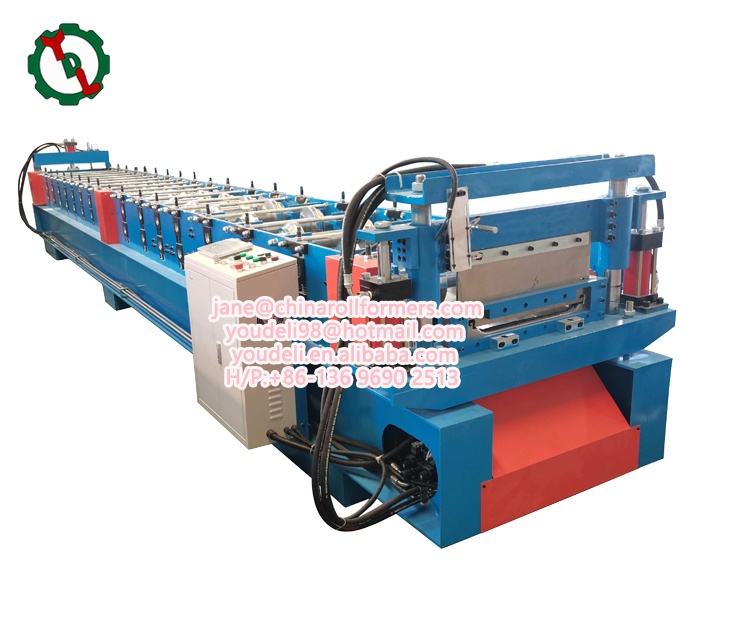

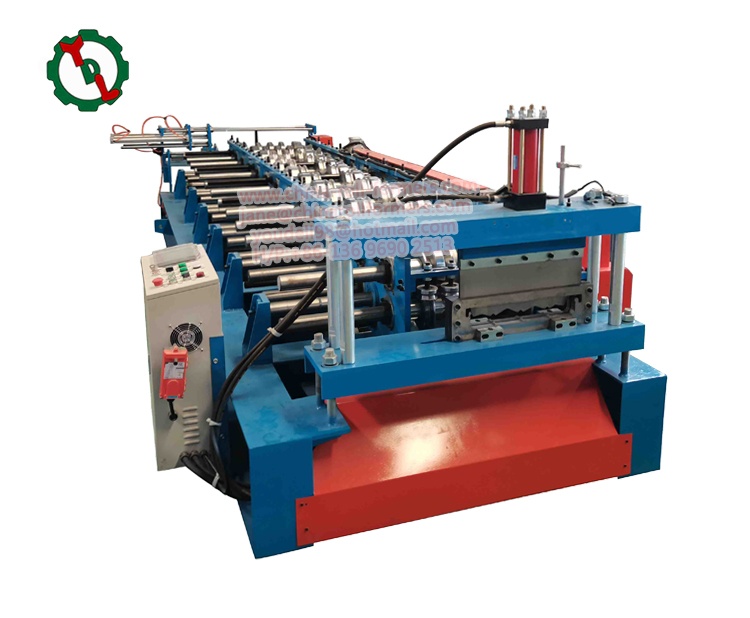

The roll forming device is very effective and simple to operate. The machine can create thousands of feet of standing seam panel each day because to its automated operation. Additionally, it is effortlessly portable from one job location to another because to its compact form.

The Automatic Portable Standing Seamless Panel Sheet Metal Mobile Roll Forming Machine Roof Seamer's capacity to create seamless panels is one of its main benefits. This indicates that there aren't any fasteners or joints, which helps to prevent leaks and ensures long-lasting durability.

Additionally, the machine is able to create standing seam panels that are exactly sized to fit the roof. This guarantees that the roof is totally watertight and that there are no gaps or overlaps.

This equipment is not only efficient and long-lasting at producing standing seam roofs, but also environmentally beneficial. By using seamless panels instead of caulking, roofing activities produce less waste and have a less negative environmental impact.

The automatic mobile roll forming machine for sheet metal standing-seam panels The invention of Roof Seamer has revolutionized the roofing sector. Its cutting-edge technologies and inventive design have completely changed how we think about roofing. This machine is rapid and effective in producing seamless panels thanks to becoming the go-to choice for roofing contractors across the world.