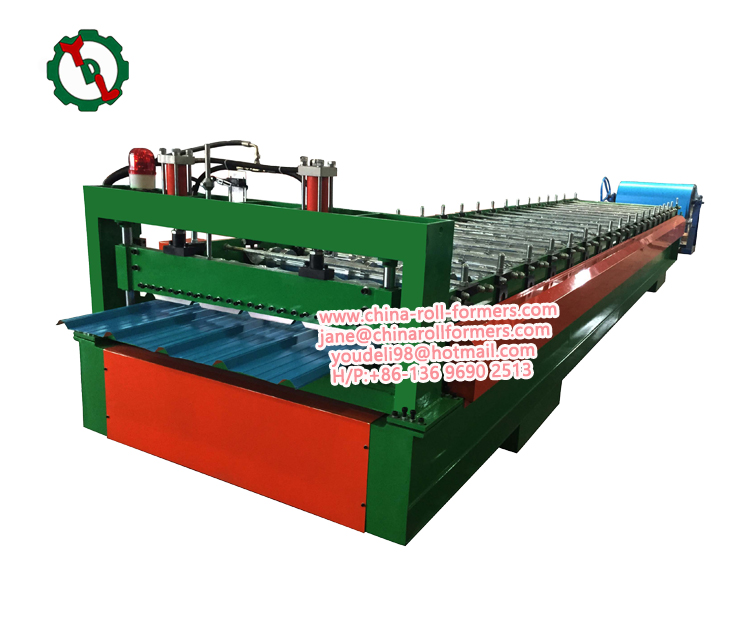

A specialized piece of equipment is used to produce steel plate concrete slab floor decking panels for use in construction, and it is called a roll forming machine. The machinery is versatile, effective, and dependable, and it is frequently used in the construction sector to quickly make high-quality floor decking panels.

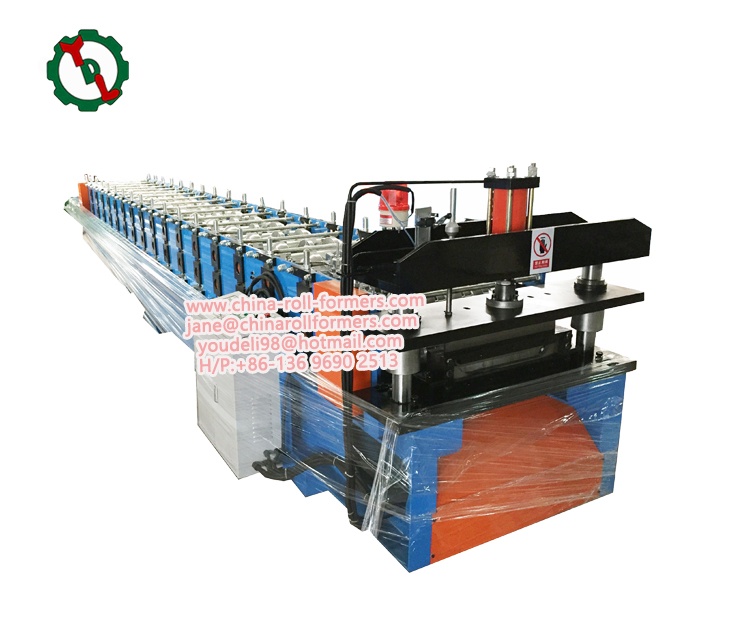

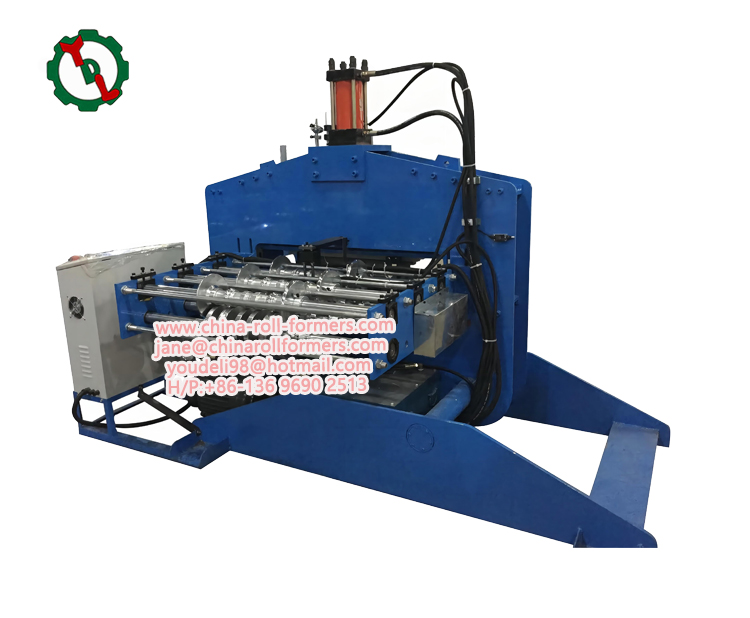

The machine's cutting-edge technology enables it to shape steel coils into floor decking panels with a consistent thickness and precise measurements. A number of rollers in the machine shape and mold the steel coil into the appropriate shape. The result is a floor decking panel that is trustworthy, sturdy, and able to endure the demands of contemporary construction.

There are many uses for the steel plate concrete slab floor decking panel roll forming machine. It can be utilized to make floor decking panels for steel constructions, multi-story buildings, and several other building projects. The device is intended to form various floor decking panel shapes, such as trapezoidal and wave varieties.

Fully automated and with little need for supervision, the device. It has a user-friendly interface that makes it simple for operators to manage and keep an eye on the production process. In addition to being safe to operate, the equipment has a number of safety mechanisms that shield the operators from potential risks.