Floor Deck Machine Introduction

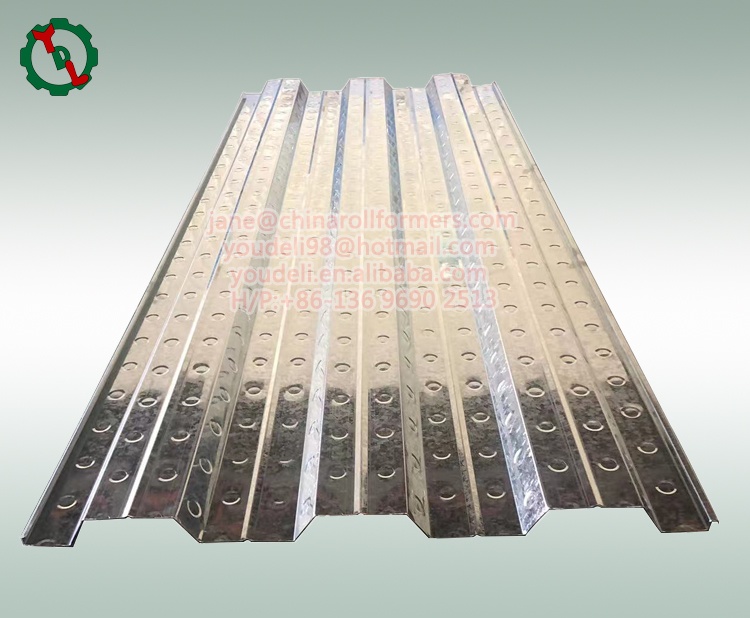

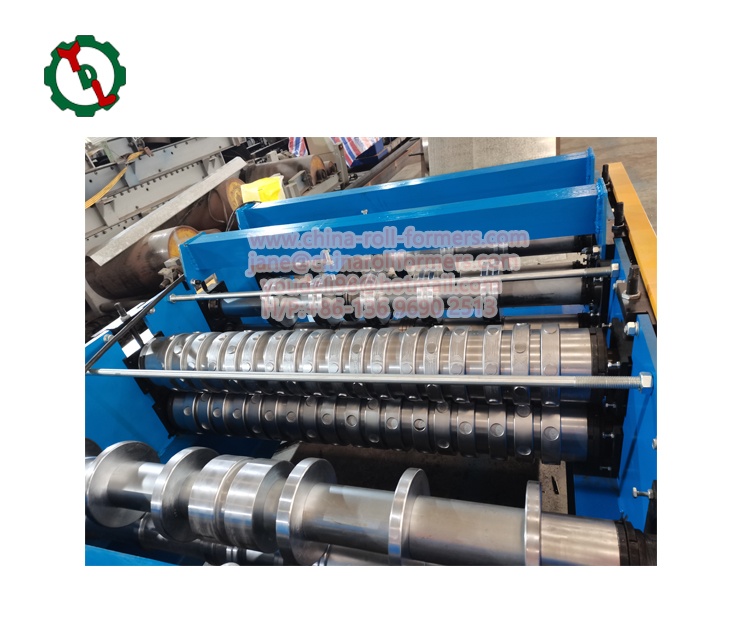

The floor deck machine is a specialized piece of equipment used in the construction industry to produce metal floor decking panels. These panels are commonly used in composite steel deck construction, providing structural support and acting as a formwork for concrete floors. The machine typically consists of a series of rollers and dies that shape the metal sheets into the desired profile. It is essential for efficiently producing high-quality floor decking panels that meet the specific requirements of construction projects.

The floor roll forming machine is a vital piece of equipment in the floor production process. The main task of this plant is the precise and long-lasting conversion of base materials such as galvanized steel coils into floor panel profiles. Floor Roll Forming Machines use continuous roll forming technology to ensure high quality output to meet the needs of various construction projects.

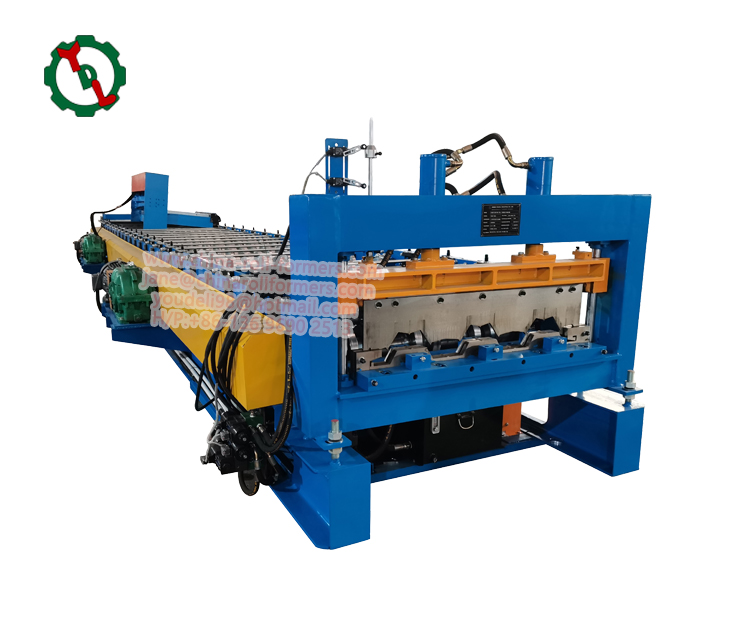

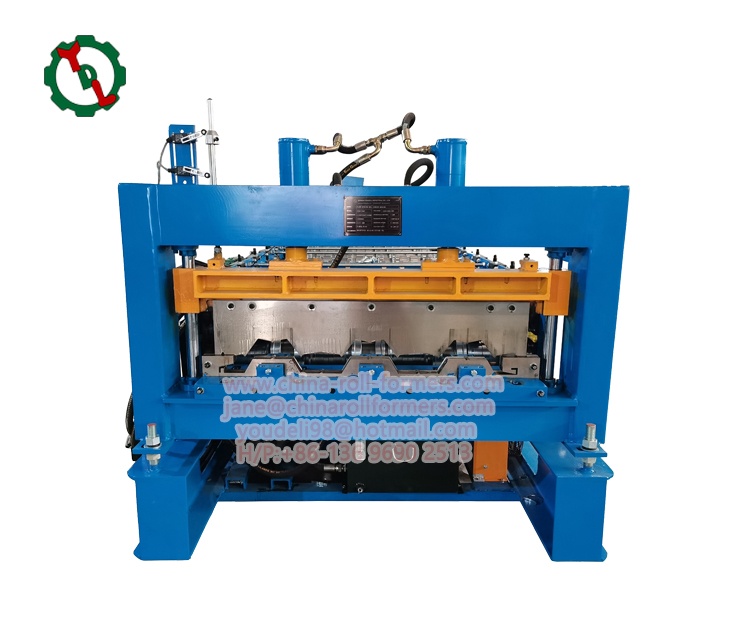

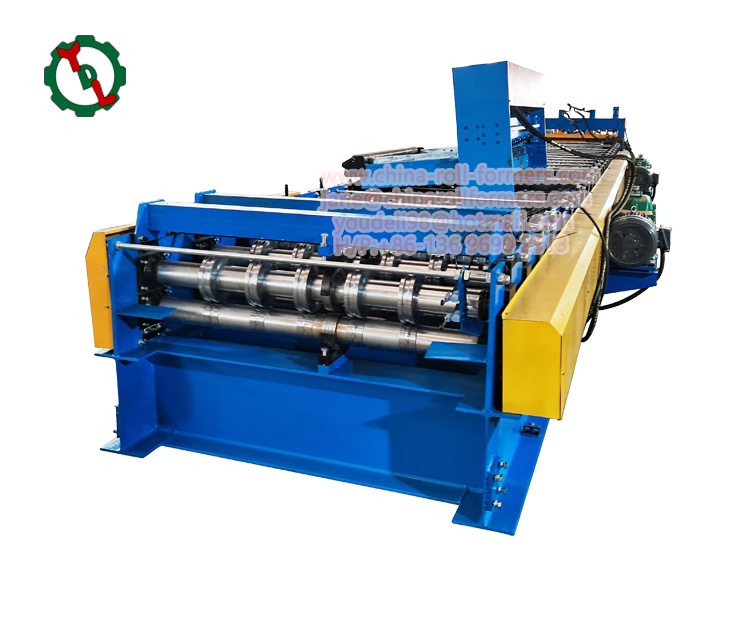

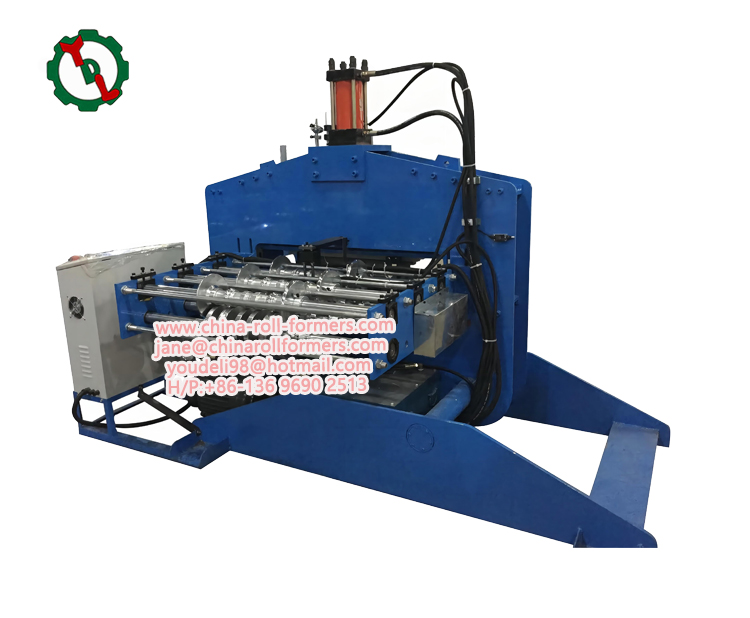

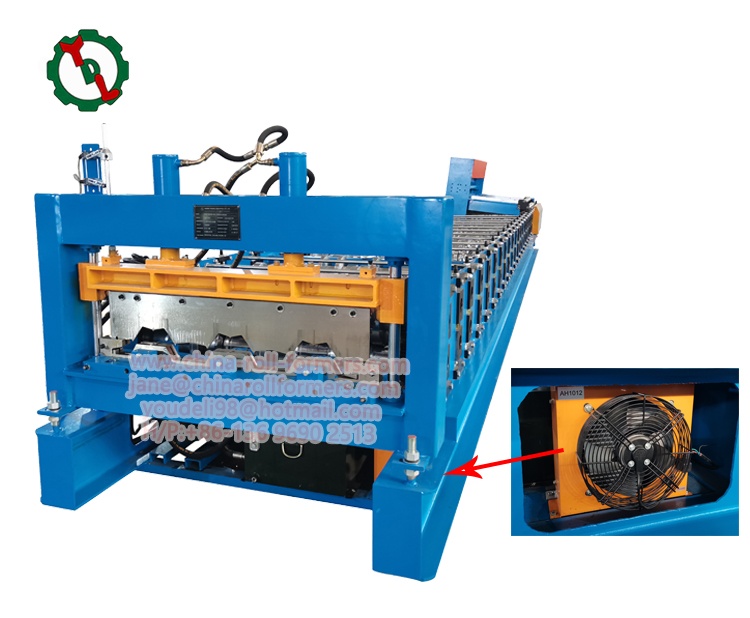

Our YX50-1000 decking machine includes several key components such as uncoilers, roll forming systems, cutting tools, hydraulic systems and control panels. Simple to operate, the manufacture of floor panels is achieved by feeding raw material rolls into a roll forming system and using cutting equipment to cut to precise lengths. The control panel provides easy machine control and adjustment, while the hydraulics provide the necessary power.

Advantage

- Efficient production:

Our machines have a high production speed, which can complete large orders on time. Its automated functions reduce labor input and increase production efficiency, resulting in cost savings.

- Accuracy and Consistency:

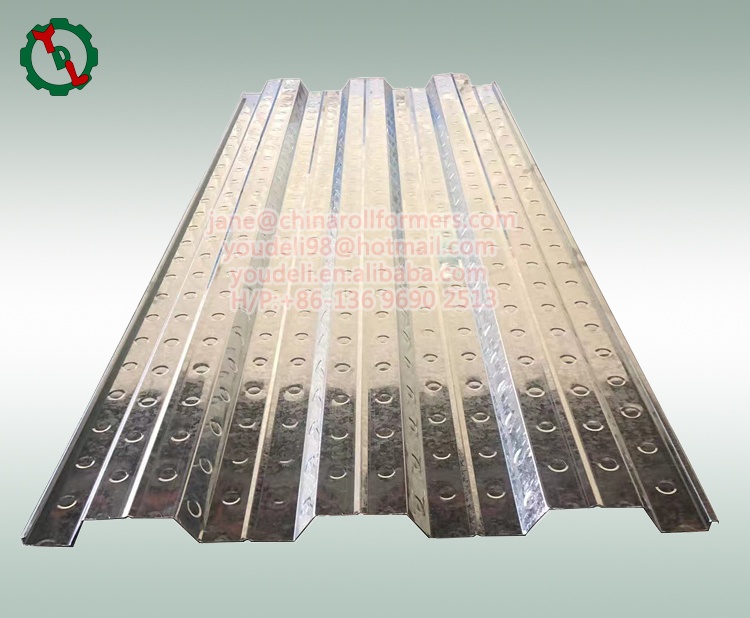

Floor roll forming machines ensure accurate and even contours of floor panels by eliminating variances and imperfections. This helps ensure the floor’s compatibility with other building elements, ensuring consistent dimensions, smooth surfaces and precise perforations.

- Flexibility:

The machine has a wide range of applications and can produce various floor finish profiles to meet the needs of different design specifications. It allows you to customize in terms of thickness, width and shape to meet the unique needs of various customers.

- Durability:

The floor produced by the floor roll forming machine has excellent durability. Galvanized steel as the main raw material is not only strong in load bearing capacity but also resistant to corrosion, combined with the roll forming process to ensure long-term reliable performance.

Floor roll forming machines have a wide range of applications in the construction sector to manufacture various types of floors, such as infrastructure projects, residential complexes, commercial and industrial buildings. Floor panels play an important role in construction because of their stability, fire resistance, and sound insulation, which act as a solid foundation for concrete slabs. Floors of different designs, such as laminate floors, steel roof panels and mezzanine floor systems, etc., can be produced with floor roll forming machines.

To ensure long-term efficient operation of your floor roll forming machine, regular maintenance is required, including cleaning debris, checking electrical connections and lubricating mechanical parts. At the same time, in order to ensure the safety of the workplace, operators should observe safety precautions, wear appropriate protective equipment, and receive appropriate training and supervision. Floor roll forming machines are an integral part of the floor manufacturing process, increasing productivity, quality control while reducing downtime, ideal for the construction industry.

Machine Features

- Time-saving: The floor deck machine is very efficient and can produce metal flooring in a short time. This means you can complete your construction project and move on to the next phase of your project faster. In the long run, this could save you a lot of time and money.

- Cost-effective: Flooring machines are cost-effective because they can produce high-quality metal floors at a lower cost than traditional construction methods. This is because they require less labor and materials, saving you a lot of money in the long run.

- Strong and Durable: The metal floors produced by the floor covering machines are very durable and strong. They can withstand heavy loads and are resistant to fire, water and other environmental elements. This makes them an ideal choice for commercial and industrial buildings that require strong, durable floors.

- Customizable: The floor paving machine can produce metal flooring in various sizes and shapes. This means that you can customize your metal deck to meet your specific construction needs. This helps you achieve your goal building goals more efficiently and effectively.

- Easy to install: The metal floor produced by the flooring machine is easy to install. They can be installed quickly and easily on the job site, saving you a lot of time and money in the long run.Types of floor covering machines

Application of Floor Deck Machine

Metal decks are created using floor deck machines and are utilized as structural elements in multi-story buildings. This device can be used in a variety of construction projects, including those involving industrial, residential, and commercial structures.

The speed and efficiency that a floor deck machine adds to the construction process is one of the main advantages. This device makes it possible to build metal decks on-site and as-needed, cutting down on long lead periods and high transportation expenses.

The versatility it offers in terms of design options is an additional advantage of employing a floor deck machine. To satisfy the particular requirements of a project, the machine may build decks in a variety of sizes and shapes.

Numerous structural designs, such as composite beams, concrete topping slabs, and precast slabs, can be accomplished through modification.

A high standard of quality control is also ensured while using a floor deck machine. In order to ensure that the finished product is of the highest caliber and durability, the machine is built to make metal decks that adhere to rigid industry requirements. As a result, the building will last longer and require less regular upkeep.

The amount of waste produced during construction is also greatly reduced by floor deck machines, making them environmentally beneficial. Floor deck machines generate decks with minimal to no waste materials, in contrast to conventional techniques, which frequently require cutting and shaping metal sheets.

The floor deck machine is a useful device that can greatly enhance the building process. It offers a high level of quality control, accelerates the manufacture of metal decks, and allows for flexible design. The construction sector benefits from this since it enables quicker, more effective, and environmentally friendly construction projects.

Parameter:

| Model NO. | YX50-1000 |

| Size | 11700*2200*1200mm |

| Weight | 12000KGS |

| Voltage | 220V/60HZ,3PH/ or as Request |

| Electric Motor Power | 11KW*2pcs |

| Servo Motor Power | 7.5KW |

| Thickness | 0.8-1.6mm |

| Forming Steps | 24 |

| Forming Speed | 0-18m/min |

| Rib Height of Decking | 50mm |

| Effective Width | 1000mm |

| Material Width | 1219mm |

| Tolerance for cutting | ±2mm |

| Material | GI PPGI Steel |

| PLC Program Control System | Original Taiwan Delta / Siemens / Schneider |

| After-Sale-Service | Online 24hours/Field Support |

| Service | Provide Engineer to Install The Machines

|

video

(1) 5MT*1250MM Manual Uncoiler;

(2) Main Roll Forming Machine for Web Decking;

(3) Feeding Table;

(4) Hydraulic System( Solenoid Valve Brand: YUKEN );

(5) PLC Computer Controlling System with Touch Screen; ( Brand: Delta for Frequency Changer, PLC, Touch

Screen and other parts, Omron for Encoder );

(6) Hydraulic Flat Pre-Cutting Device( Flat Cutter, with encoder for counting length and quantity);

(7) Hydraulic Post Cutting Device( Blade Material: Japan Import SKD11 Steel, Stop Scrap Cutting );

(8) Run Out Tables ( 4pcs );

(9) Tools;

(10) Operation Manual.

OUR SERVICES

1、Installation and instruction

A. If customers come to our facility to inspect the equipment, we’ll show them how to install and operate it. We’ll also personally train your employees’ technicians.

B. In lieu of an in-person visit, we will email you an installation manual and a video tutorial.

C. If the buyer requires our specialist to travel to your local factory, kindly make arrangements for board, lodging, and any other necessities.

2、second. AFTER SERVICE

A. The entire machine has a one-year warranty.

B. Telephone or email technical help available 24/7.

C. We will fix the machine for free if there is ever a problem within a year.