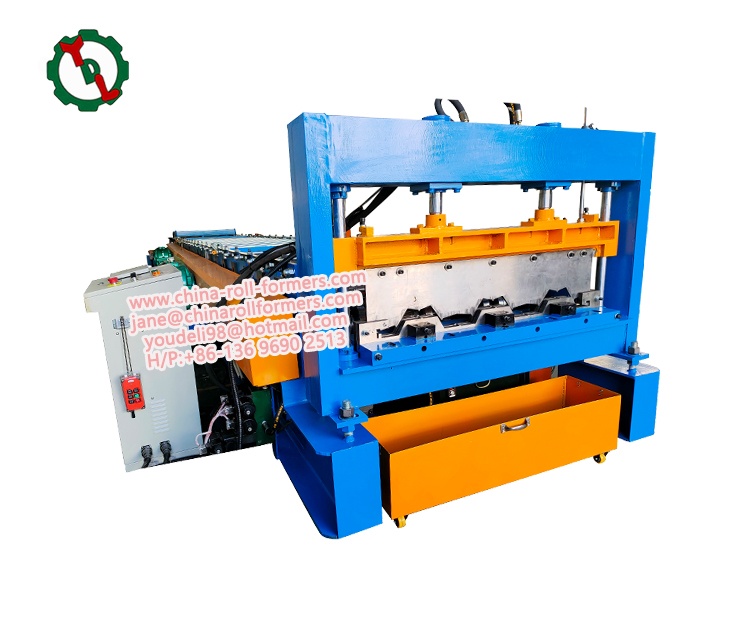

- Floor Decking Roll Forming Machine

For industrial and commercial structures, tough, long-lasting raised floor decks are made using cutting-edge steel floor decking roll forming machinery. These tools are employed in the building sector to produce a variety of waterproof, fireproof, and energy-efficient deck profiles and designs.

Modern technology in the steel floor decking roll forming machine allows it to form metal sheets into different shapes, widths, and thicknesses. Sheet feeder, adjustable guide rail, roll forming system, hydraulic cutter, control system, and run-out table make up this machine. The steel sheet enters the roll forming system after passing via the sheet feeder, which uses a hydraulic mechanism to modify the guide rail.

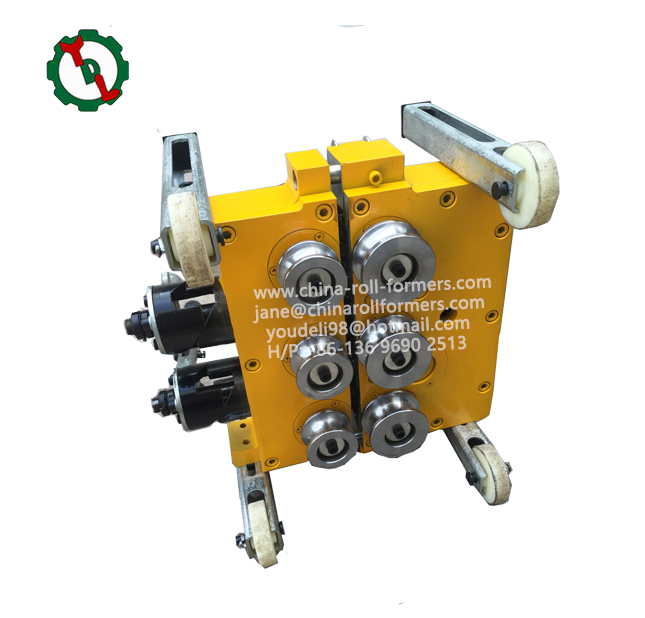

Multiple sets of rollers make up the roll forming system, which shapes the metal sheet into the desired pattern and contour. The run-out table then gathers the finished product after the metal sheet has been cut to the required length by the hydraulic cutter. Because the entire process is mechanized, the steel floor decks that are manufactured are of consistently high quality.

The roll forming machine's steel floor decks have significant benefits over conventional concrete decking. They save money and speed up construction since they are lightweight, simple to install, and require less concrete. The decks can be employed in a variety of structures, including commercial buildings, industries, and warehouses.