- Tile Roofing Machine

Roof Tile roll forming machine: A New Technology in Roofing Industry

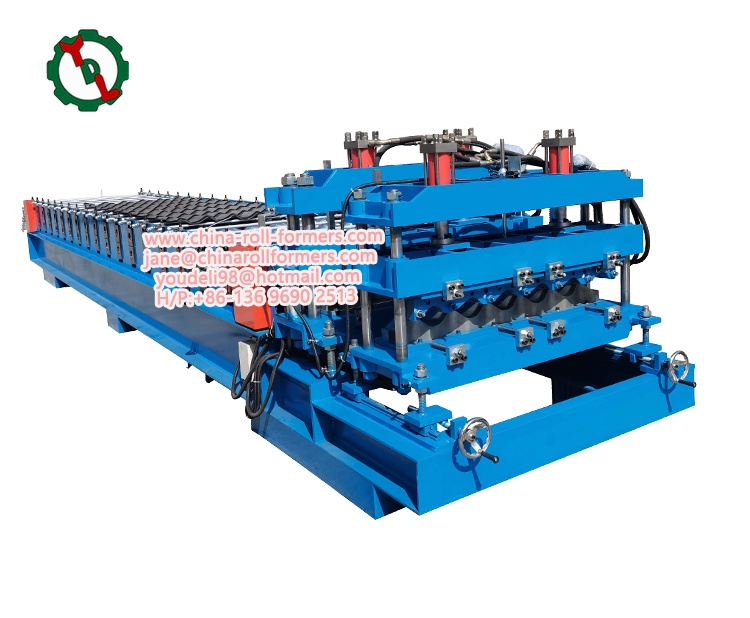

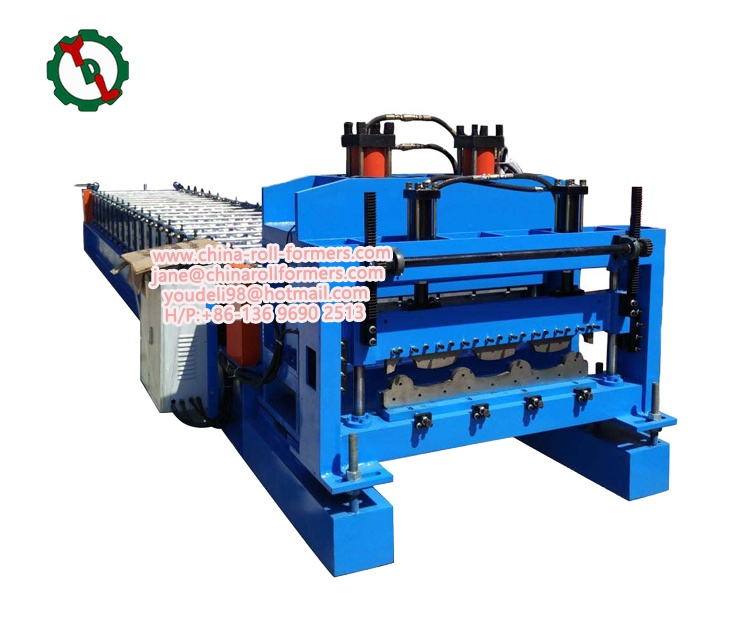

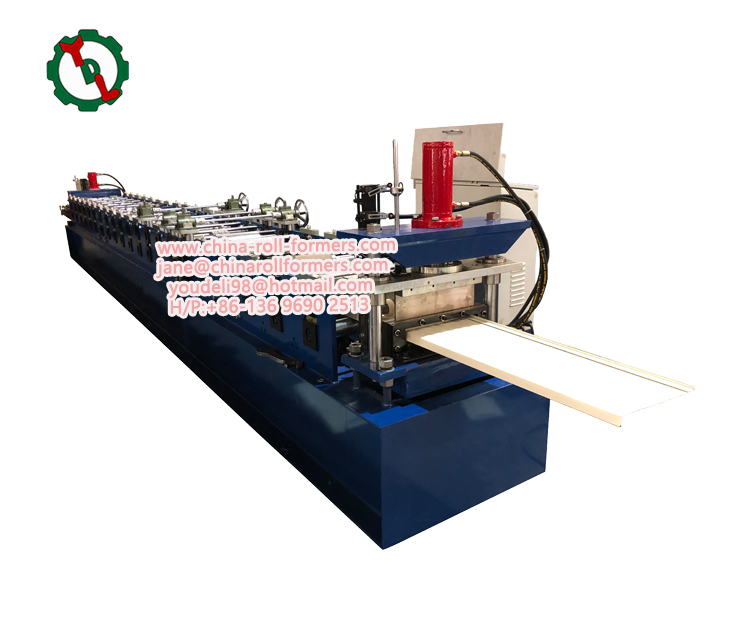

Metal sheets are shaped and cut into tile roofing panels using a type of roll forming equipment called a Roof Tile roll forming machine. This machine is frequently employed in the construction sector to produce roofing systems that are of excellent quality, durability, and aesthetic appeal.

The Roof Tile roll forming machine consistently shapes the metal sheets into the appropriate profile using a set of rollers. Using automatic shearing and cutting mechanisms, the machine precisely cuts the tiles to the necessary length and shape. The completed panels are then packaged and stacked for delivery to the installation location.