All Product

Welcome to explore our comprehensive product lineup featuring cutting-edge machinery like the Double Layer Roll Forming Machine, Purlin Roll Forming Machine, Electric Seaming Machine, and more. Welcome your consultation and purchase, we look forward to providing you with a quality shopping experience!

All Product List

- PU Sandwich Panel Machine

PU sandwich panel machines are essential equipment in the construction industry, offering a wide range of benefits such as high efficiency, cost-effectiveness, and quality control. With their robust construction, precision engineering, and customization options, these machines are ideal for producing insulated sandwich panels for use in buildings.

- Hydraulic Uncoiler

Automatic Hydraulic Uncoiler: Compact and Efficient Coil Unwinding Solution

An automatic hydraulic uncoiler is a specialized industrial equipment used to unwind and straighten coils of metal sheets, cables, wires, and diverse materials. It features a hydraulic or motorized mandrel, a support structure, and a control system that automatically adjusts the speed, tension, and direction of the coil unwinding process.

This advanced equipment is designed to save time and labor while ensuring precise and safe unwinding of coils up to several tons in weight and width. It is widely used in manufacturing, construction, automotive, energy, and other industries that require high-quality and efficient coil processing.

One of the main advantages of an automatic hydraulic uncoiler is its compact design and easy installation. It can be customized to fit different coil sizes and shapes, and can be installed both indoors and outdoors, depending on the production needs and space availability.

Moreover, an automatic hydraulic uncoiler reduces material waste, minimizes downtime, and improves safety for workers, as it eliminates the need for manual handling and cutting of coils, which can be hazardous and time-consuming. With its advanced sensors, brakes, and controls, the hydraulic uncoiler maintains a constant and stable unwinding speed and tension, which ensures smoother and more consistent processing of the coils.

In addition, the hydraulic or motorized mandrel of the uncoiler can be easily operated with handheld or wireless remote controls, which increases the operator's mobility and productivity. The support structure can also be adjusted to accommodate various types of materials, from thin foils to thick plates.

- C Purlin Machine

The C channel roll forming machine is fully automated and requires limited manual intervention, making it an excellent option for large-volume production. Additionally, it is equipped with sensors that detect any abnormalities, minimizing wastage.

- Purlin Machine

Metal carrying channel roll forming machines are essential equipment in the construction industry, offering precision, efficiency, and versatility in producing metal carrying channels for various building applications.

- Roofing Sheet Roll Forming Machine

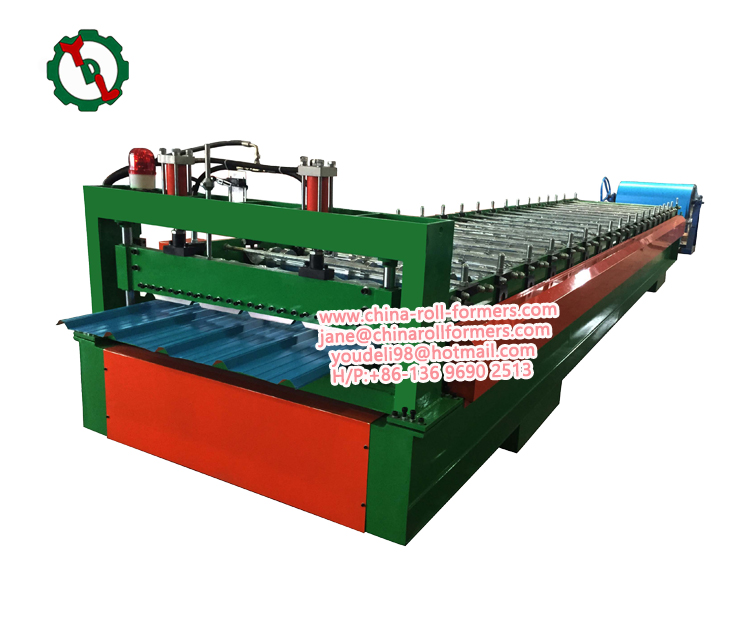

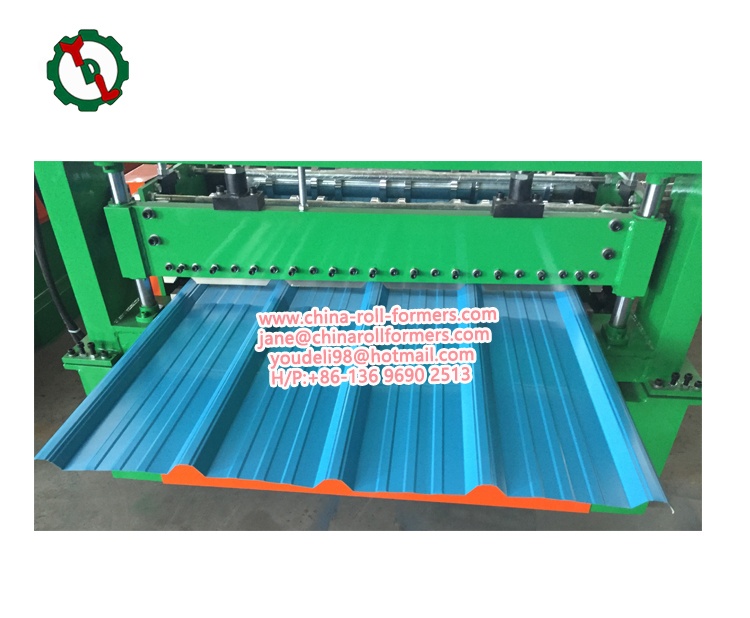

The twins cladding roll forming machine feeds two metal plates simultaneously, cutting them into various profiles such as standing seam panels, corrugated panels, and ribbed panels. These user-friendly machines require minimal maintenance, operate continuously, and feature advanced computer control systems for real-time monitoring and adjustment of production processes.

- Trapezoidal Roofing Machine

The most popular trapezoid rib roof tile forming machines in the construction equipment field. For structures of all sizes, both tools can be used to produce high-quality wall and roof systems.

The trapezoid rib roof tile forming machine is designed to produce trapezoid rib roof tiles. The machine produces exceptionally strong, weather-resistant shingles, ideal for use in locations where heavy rain and other inclement weather is common.

trapezoid rib Roof Tile Forming Machines are very efficient for developing high quality and long lasting wall and roof systems used in residential and commercial structures. Whether you are building a small residence or a large commercial complex, these tools will undoubtedly help you complete the task quickly and efficiently.

Product Categories

Hot Articles

Channel rolling machines are specialized for bending structural shapes like channels and angles, offering precision and efficiency for specific bending requirements in industries such as construction and manufacturing.

- March 11, 2024

- September 7, 2023

The roll forming of roll forming equipment uses sequentially configured multi-pass forming rolls to continuously bend metal sheets such as coils and strips laterally to form profiles with specific cross-sections. The roll forming process is suitable for producing long workpieces of equal cross-section in large batches, especially for large-volume products with an annual output of millions of pieces. The roll forming process is beneficial and has considerable economic benefits. At the same time, it can also be combined with various processes to form a continuous production line.