Электрические шовные машины are critical in numerous industries due to their efficiency, precision, and reliability in creating durable seams. These machines automate the seaming process, ensuring consistency and quality, which is crucial in industries where precision and durability are paramount. This article will explore various industries that commonly use it, delving into their applications and the benefits they offer.

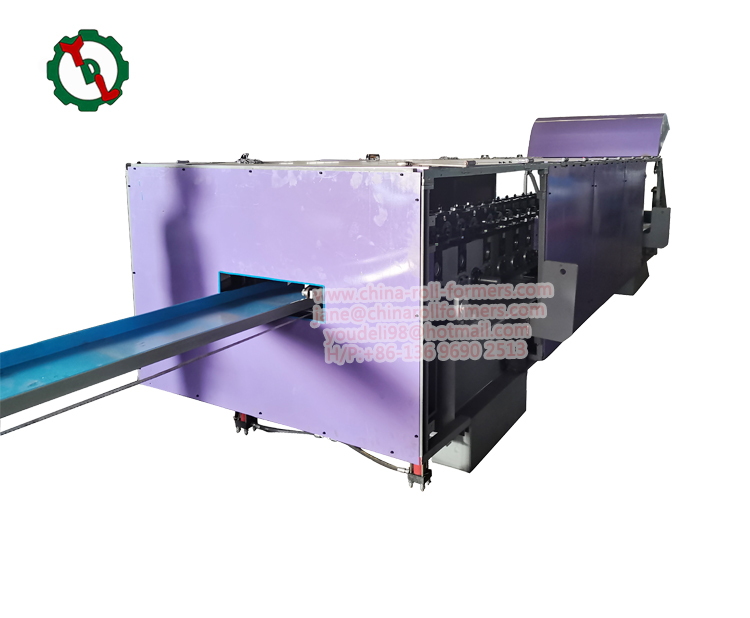

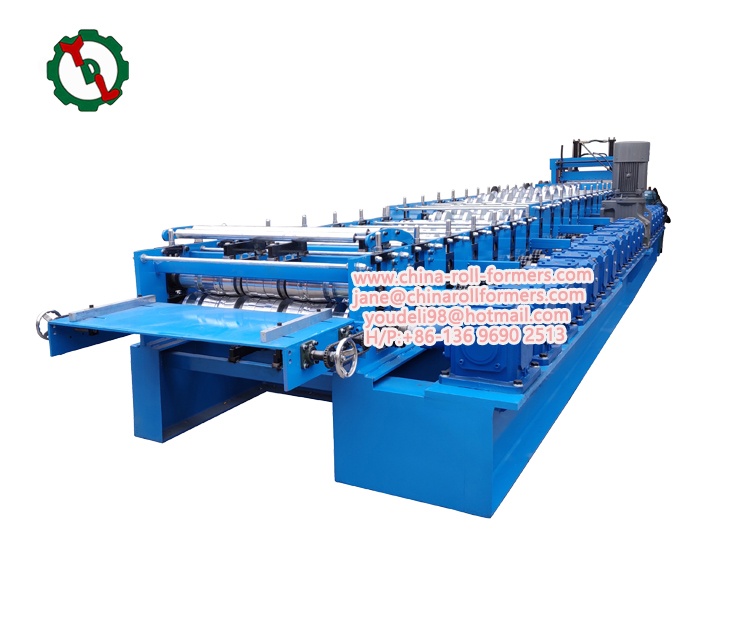

Overview of Electric Seaming Machines

An electric seaming machine is a device designed to join two pieces of material together by creating a seam. These machines are widely used in manufacturing and production lines where speed, accuracy, and consistency are essential. The technology behind electric closing machines allows them to handle various materials, including metal, fabric, plastic, and composites, making them versatile tools in many sectors.

Key Features of Electric Seaming Machines

- Precision: They offer high precision in creating seams, ensuring the joints are strong and consistent.

- Эффективность: These machines can significantly speed up the production process, reducing the time and labor required to create seams manually.

- Универсальность: They can handle different types of materials, making them suitable for various applications across multiple industries.

- Долговечность: The seams created by electric closing machines are typically more durable and reliable than those created by manual methods.

Industries That Commonly Use Electric Seaming Machines

1. Food and Beverage Industry

The food and beverage industry extensively uses electric seaming machines, particularly in the packaging sector. Seaming machines are crucial for sealing cans, bottles, and other containers, ensuring the products are airtight and preserving their quality.

- Canning: They are used to seal cans of food and beverages, providing an airtight seal that helps preserve the contents.

- Bottling: In the bottling process, these machines ensure the caps or lids are securely fastened, preventing contamination and spillage.

The precision and reliability of they are vital in this industry, as even a small defect in the seam can lead to contamination or spoilage of the product.

2. Automotive Industry

In the automotive industry, electric closing machines are used to join various components, particularly in the assembly of car bodies and parts. The precision and strength of the seams are crucial for the safety and durability of vehicles.

- Body Assembly: They are used to join panels and other components of the car body, ensuring they are securely attached.

- Part Fabrication: These machines are also used in the fabrication of smaller parts, such as fuel tanks and exhaust systems, where strong seams are necessary for performance and safety.

The automotive industry benefits greatly from the efficiency and precision of electric seaming machines, which help maintain high production standards and ensure the safety of the vehicles.

3. Textile and Apparel Industry

The textile and apparel industry utilizes electric closing machines to create strong and precise seams in various garments and fabrics. These machines are essential in ensuring the durability and quality of the final products.

- Garment Manufacturing: They are used in the production of garments, creating seams that are strong and neat.

- Home Textiles: In the production of home textiles such as curtains, bed linens, and upholstery, these machines ensure the seams are durable and aesthetically pleasing.

The versatility of electric seaming machines allows them to handle different types of fabrics, making them indispensable in the textile and apparel industry.

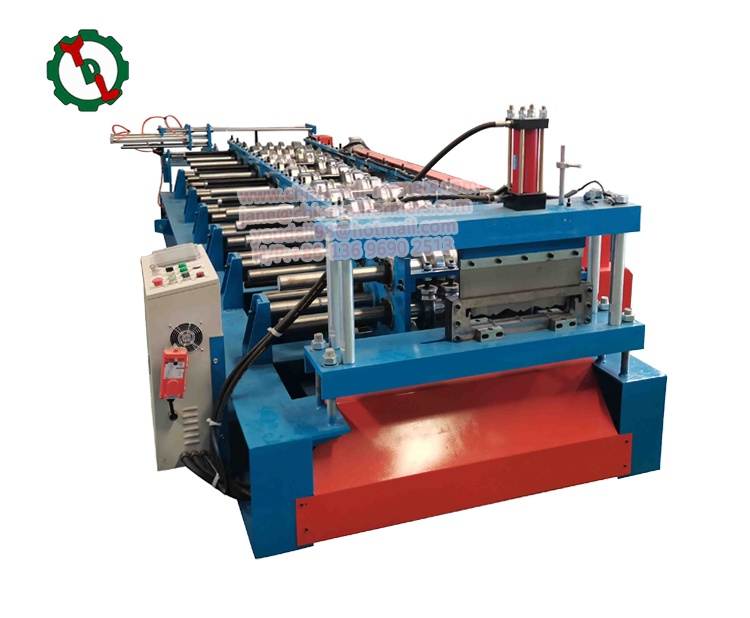

4. Metalworking Industry

In the metalworking industry, they are used to join metal sheets and components. These machines provide the precision and strength needed to create durable seams in metal products.

- Sheet Metal Fabrication: They are used to join metal sheets in various applications, such as ductwork, enclosures, and structural components.

- Container Manufacturing: These machines are also used in the production of metal containers, such as barrels and tanks, ensuring the seams are airtight and strong.

The ability to create precise and durable seams in metal makes electric closing machines valuable tools in the metalworking industry.

5. Aerospace Industry

The aerospace industry requires high precision and reliability in the assembly of aircraft components. They are used to join various parts of the aircraft, ensuring the seams are strong and precise.

- Aircraft Assembly: These machines are used to join panels and other components of the aircraft, ensuring they are securely attached.

- Component Fabrication: Electric seaming machines are also used in the fabrication of smaller components, such as fuel tanks and structural parts, where strong seams are necessary for performance and safety.

The aerospace industry benefits from the high precision and reliability of electric closing machines, which help ensure the safety and durability of aircraft.

6. Packaging Industry

The packaging industry relies heavily on electric closing machines to create secure and durable seams in various packaging materials. These machines ensure the products are properly sealed and protected.

- Flexible Packaging: They are used to create seams in flexible packaging materials, such as pouches and bags, ensuring they are securely sealed.

- Rigid Packaging: These machines are also used in the production of rigid packaging, such as boxes and containers, where strong seams are necessary for structural integrity.

The packaging industry benefits from the efficiency and precision of electric seaming machines, which help ensure the quality and durability of the packaging.

Benefits of Using Electric Seaming Machines in Various Industries

- Consistency: They provide consistent results, ensuring the seams are uniform and reliable.

- Speed: These machines can significantly speed up the production process, reducing the time and labor required to create seams manually.

- Precision: The high precision of electric seaming machines ensures the seams are accurate and strong, which is crucial in industries where safety and durability are paramount.

- Экономическая эффективность: By automating the seaming process, these machines can reduce labor costs and increase efficiency, leading to cost savings in the long run.

- Универсальность: They can handle different types of materials and applications, making them suitable for various industries.

Заключение

Electric seaming machines are indispensable tools in many industries, including food and beverage, automotive, textile and apparel, metalworking, aerospace, and packaging. Their ability to create precise, durable, and consistent seams makes them essential for maintaining high production standards and ensuring the quality and reliability of the final products. By understanding the various applications and benefits of electric closing machines, businesses can make informed decisions about investing in these versatile and efficient tools.

In summary, the widespread use of electric seaming machines across multiple industries underscores their importance in modern manufacturing and production processes. Their efficiency, precision, and versatility make them valuable assets in ensuring the quality and durability of products, ultimately contributing to the success and competitiveness of businesses.