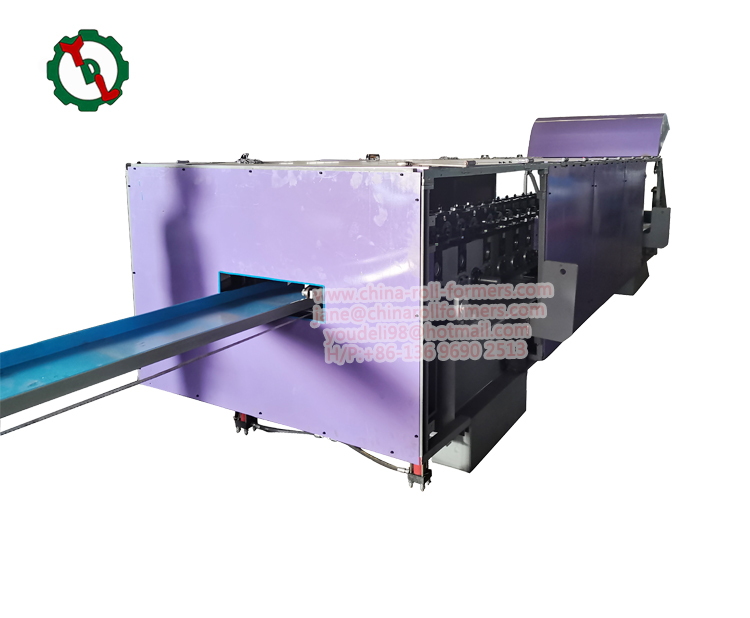

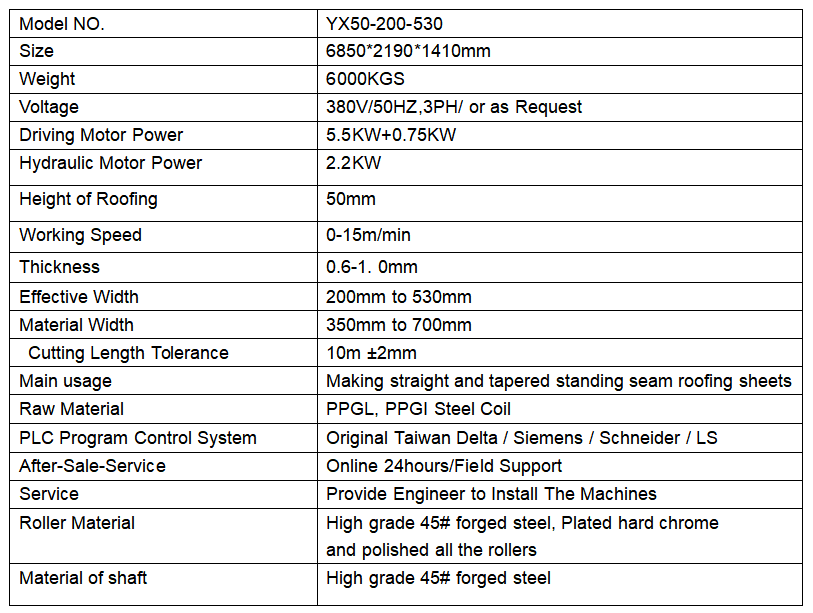

The YX50-200-530 Portable Standing Seam Roofing Machine has an adjustable feature for quick, flawless self-adjustment. This machine is also lightweight and easily portable for convenient use on construction sites or other on-site settings. The following are some features and applications of portable standing seam roofing machine:

Особенности:

- Portability: Lightweight for easy transportation.

- Adaptability: Applicable to different types and specifications of metal materials, so it is suitable for many different roofing projects.

- Quick Setup: The machine is highly automated, easy to set up and adjust to meet the needs of different sizes and shapes of metal roofing panels.

- Efficient production: It can efficiently produce standing seam metal roofing panels, improving production efficiency.

application:

Construction Sites: Portable standing seam roofing machines are often used on construction sites for the manufacture and installation of metal roofing panels. Because of their lightness and adaptability, they are suitable for use in different construction projects.

Repair and maintenance: In addition to new construction projects, these machines are also used for metal roof repair and maintenance work. They can quickly fabricate replacement metal roof panels to repair damaged roofs.

Emergency Repair: In the event of a natural disaster or other emergency, a portable standing seam roof panel machine can be quickly deployed to repair damaged roofs, providing emergency protection.

In summary, the portable standing seam roofing machine is a flexible and efficient piece of equipment that can be used to manufacture and install standing seam metal roofing panels for a variety of construction projects and maintenance jobs. Its portability makes it ideal for high-quality metal roofing fabrication on a variety of job sites.

ОПИСАНИЕ ПРОДУКТА

ВЫКЛАДКА ПРОДУКЦИИ

ГЛАВНАЯ ОСОБЕННОСТЬ

- The plate is flat and has slick lines.

- After conducting technical research, it was found that the precise and reasonable overlapping of the plate shape and the small side with no wave effectively block water and rain.

- Cutting-edge technology: The line uses continuous coil material to produce precise and long-cutting parts with good shape, regular length, and perfect consistency after cold bending and forming. The finished product is quite sturdy and has a nice appearance.

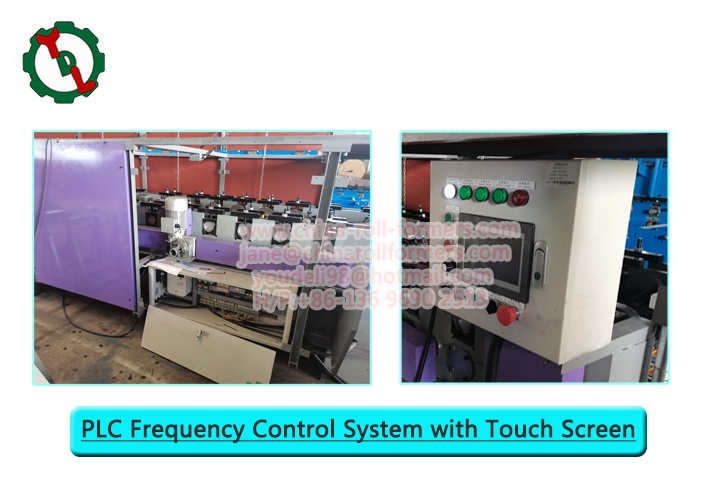

- High productivity: The line only requires 1-2 people to operate it, and the labor intensity is minimal. The running speed of the line is typically 20 meters per minute, but the production pace can be altered indefinitely between 0 and 20 meters per minute.

СЕРТИФИКАТ

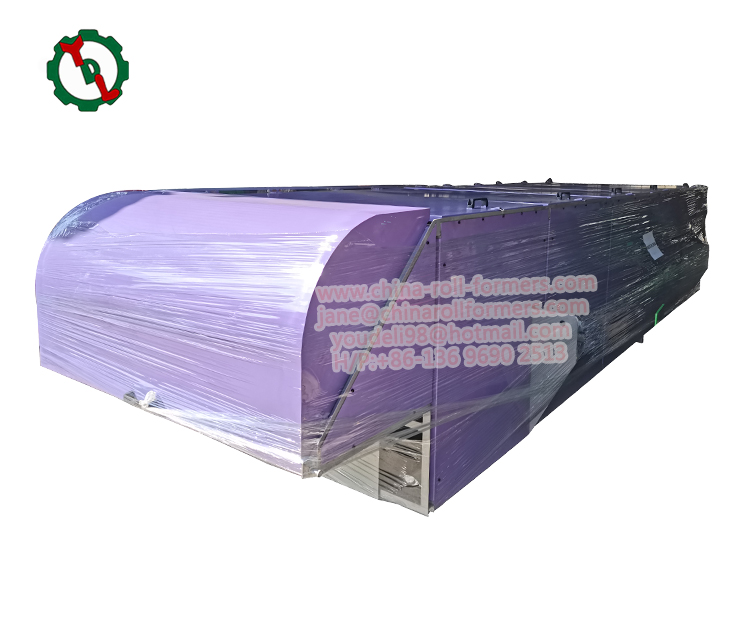

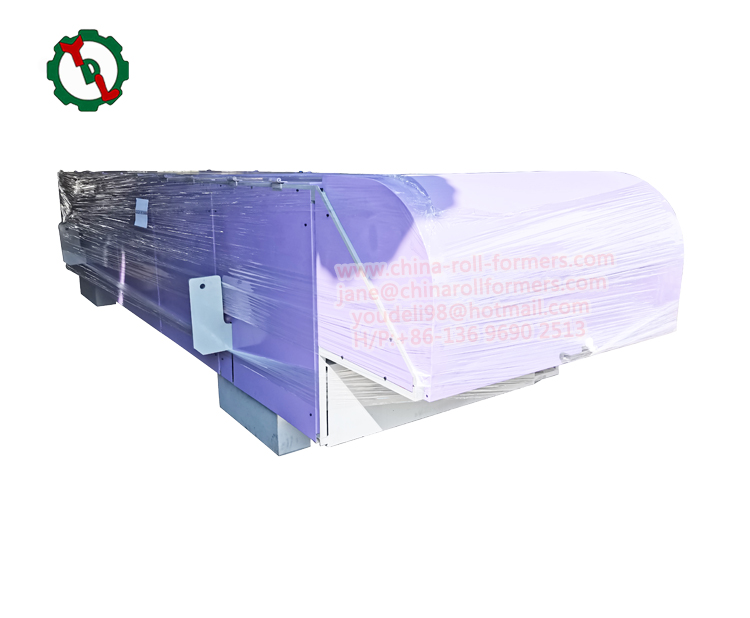

ПОГРУЗКА ГРУЗОВ

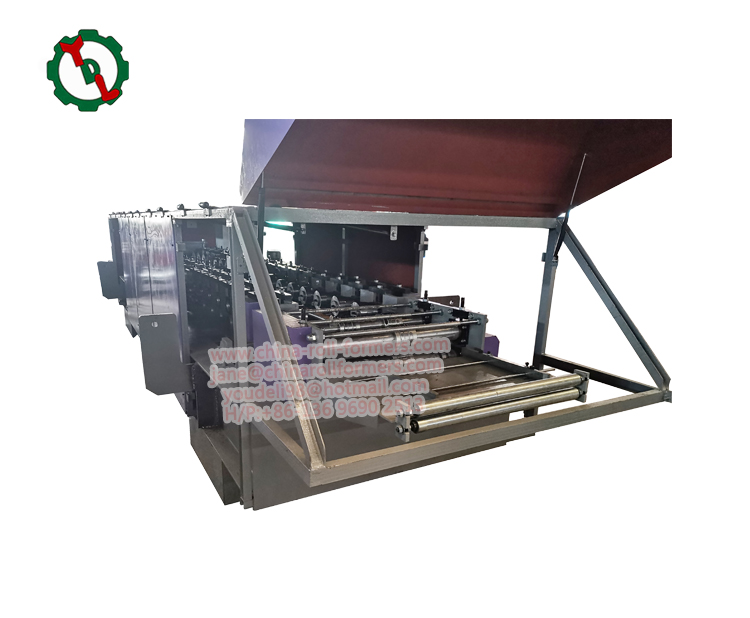

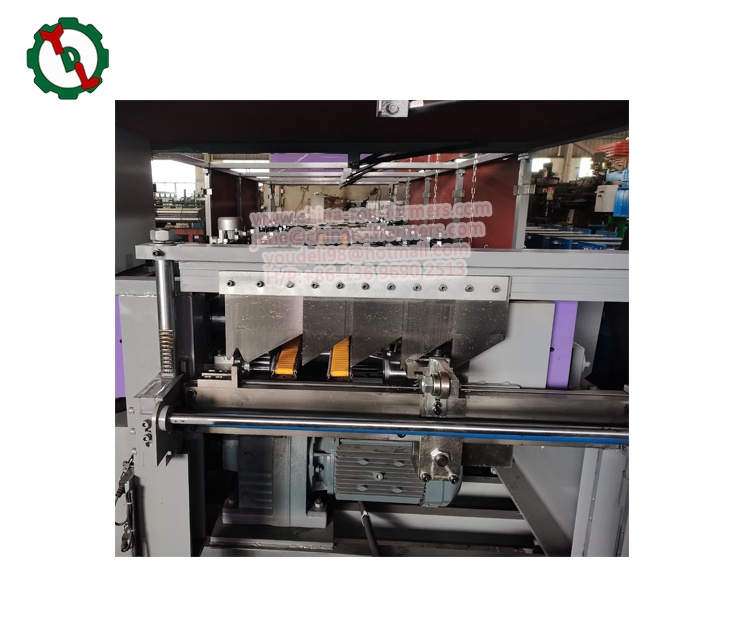

ОСИ И РОЛИКИ

MG-MN ALLOY ALLOY ENCLOSURE SHEET PROPERTIES

- Light weight: Because the substructure is light in weight, the prefabricated parts can be positioned higher. On-site lifting is simple and doesn’t require expensive lifting machinery.

- Corrosion resistance: Aluminum is a material with great corrosion resistance by nature, and this property is enhanced by prefabrication. In this way, even if the molding’s thin aluminum sheet is used for a lengthy period of time in challenging circumstances, it won’t require costly maintenance.

- Strong: Aluminum is extraordinarily strong and may be utilized to create constructions that are both light and incredibly stable.

- Strong plasticity: Aluminum is a flexible and plastic material with limitless design possibilities. Numerous processing techniques, including shaping, welding, riveting, and cutting into dynamic 3-D geometry, are possible.

- Simple bonding: You can utilize techniques like welding, riveting, fastening, and direct fixed connection in addition to the connection methods often used in the building sector. These straightforward techniques can be used to connect building materials quickly and safely.

- Recyclable: Aluminum wall and roof panels can typically be recycled in a single step, which can save 95% of the energy used in initial production.

- It can be given different surface polishing and coating treatments, such as anodizing or coating, to match the high aesthetic standards of architects and perhaps increase the useful life of aluminum components.

ADVANTAGES OF ROOFING SYSTEM

- no connection, no screw hole; the exterior of the structure is finished.

- is capable of inner and outer arc bends.

- You can select various colors and materials.

- The drainage and general waterproofing of the structure.

- which can be applied on roofs with a 1.5° slope.

- The wind pressure resistance, which is best for typhoons and storms more places (with the base plate).

- the pressure caused by heat expansion and contraction is eliminated by the river.

- Convenient and cost-effective construction, quick and easy machine winding.

- An insulating and sound-absorbing layer glue.

- free of pollution, no chemical caulking glue.

- The aging issue can be produced at the site and the roof does not require maintenance.

What is Portable standing seam roof panel machine

A tool used to produce standing seam metal roofing panels is a portable standing seam roof panel machine. On the job site, this equipment is utilized to convert flat metal sheets into roof panels that are specifically sized and shaped. The end product is a locking, high-quality metal roof that is more resilient to the elements than conventional roofing materials.

Transportability is one of the main advantages of a portable standing seam roof panel machine. On the back of a pickup truck or trailer, the machine can be readily carried to a job location. With no need for pre-fabrication or additional shipping expenses, roofers can now build panels on-site.

The machine itself has a very straightforward design and is made up of a cutting mechanism that cuts the panels to the right size and a roller system that bends the metal sheets into the desired shape. A seaming tool is another component of some machines that binds the panels together to form a watertight seal.

A portable standing seam roof panel machine can be used to create panels with greater precision, which leads to a more effective use of resources and less waste. Additionally, it makes installation faster, which lowers labor expenses and expedites the completion of more projects.

Portable standing seam roof panel makers may also be used to create metal cladding for walls and other architectural elements in addition to the roofing business. Because of their adaptability, they are an excellent choice for companies and contractors wishing to increase their skills and service offerings.

Overall, a portable standing seam roof panel machine is an important piece of equipment for the building sector since it increases the efficiency, accuracy, and adaptability of the production of metal roofing panels.