Introduction

A standing seam roll forming machine is a mechanical device used to manufacture standing seam metal roof or wall panels. Its main function is to process flat metal materials, such as steel plates, aluminum plates or copper plates, into panels with specific shapes and structures through a series of processes, which are used for roofs, walls or other external covering parts of buildings.

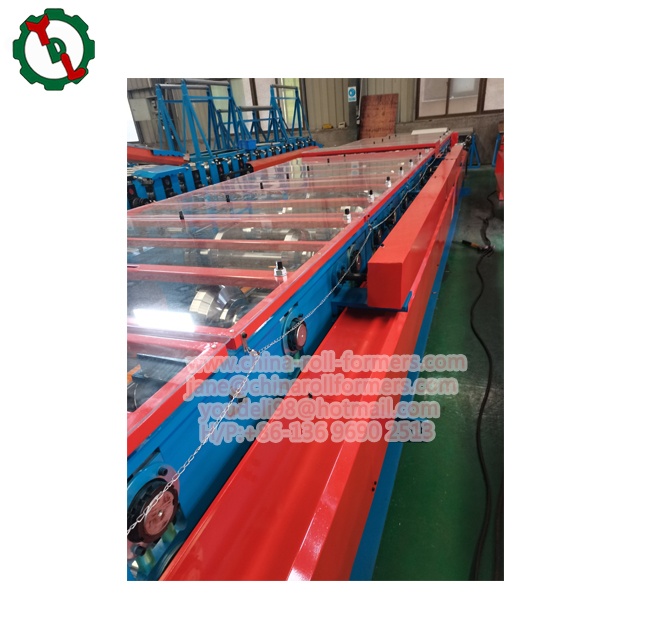

We are a professional manufacturer of rolling equipment that we can customize to specific design requirements and specifications to produce various types of panels such as standing seam metal roofing, wall cladding panels, and more. Youdeli’s vertical seam roll forming machine is highly automated, which can greatly improve production efficiency and accuracy. They are widely used in the construction industry due to their ability to create strong, durable metal panels with good water-repellent properties used to protect buildings from the weather and other external factors.

Working Principle

- Material Feeding: Flat metal materials are loaded into the machine’s feeding system, supplied in the form of reels, and then introduced into the machine one by one.

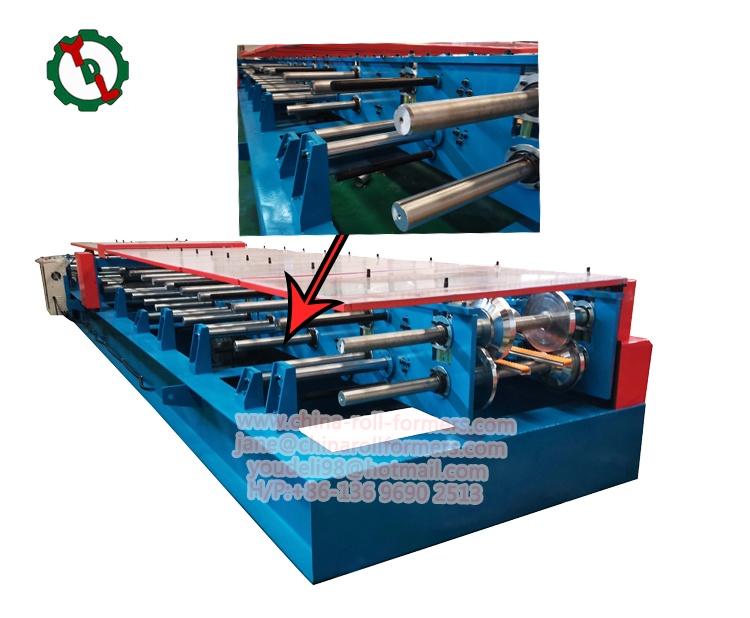

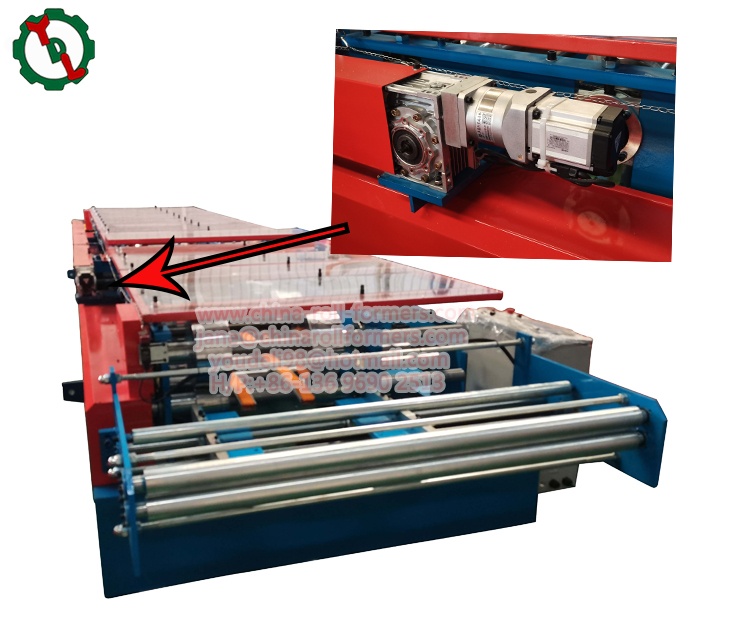

- Roll forming: After the metal materials enter the machine, they pass through a series of rollers and dies. Our communicatively designed rollers and dies are designed to machine the metal to the desired panel shape and specifications. This includes bending, curling and forming standing seams of the material.

- Cutting and sizing: After roll forming, the machine is often also equipped with a cutting device for cutting long rolls into the required length to fit specific building dimensions and designs. Our machines feature high precision to ensure the consistency of the panels.

- Output: The finished standing seam metal panel exits the output port of the machine ready for installation in the building.

Advantages of standing seam roll forming machine

Standing seam roll forming machines are effective tools for modern metal roofing and wall manufacturing, they provide an efficient, precise, high-quality production process that helps ensure that buildings have strong, durable and water-resistant exterior coverings. Standing seam roll forming machines are widely used in the field of metal roof and wall manufacturing, mainly because of the following advantages:

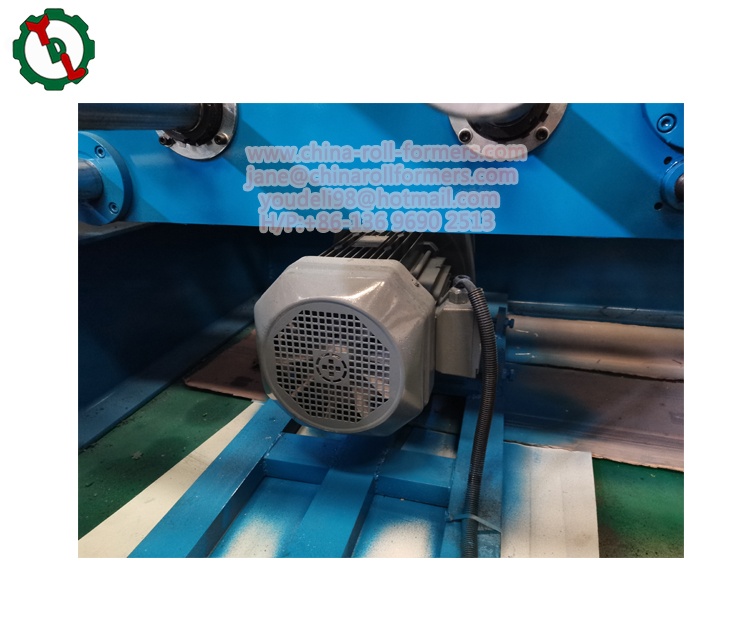

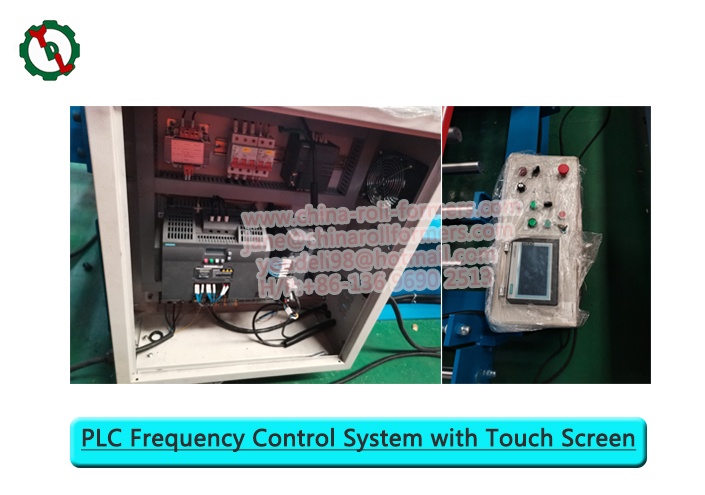

- Highly automated: Standing seam roll forming machines are highly automated production equipment capable of manufacturing a large number of panels in a short period of time. This reduces labor costs and increases productivity.

- Customization ability: In youdeli, we can customize according to customer’s requirements, and can meet the customization needs of various construction projects. We can produce metal panels of different types, specifications and lengths according to different application scenarios.

- High Accuracy and Consistency: Standing seam roll forming machines use precise rollers and die to machine the metal, so panels are manufactured with a high degree of accuracy and consistency. This helps to ensure that the panels fit together tightly when installed, increasing the waterproofing of the roof or wall.

- Reduced scrap: Due to its high-precision manufacturing process, standing seam roll forming machines can minimize the generation of scrap. This helps reduce costs and reduce resource waste.

- Improved Product Quality: Automated manufacturing processes reduce the possibility of human error, ensuring the manufactured metal panels are of a consistently high quality. Panels are manufactured for long life, durability and good performance.

- Improved safety: Compared with manual processing, the standing seam roll forming machine can reduce workers’ exposure to dangerous working environments and improve the safety of the production process.

- Applicable to a variety of materials: It can be used for different types of metal materials, including steel, aluminium, copper, etc., with strong applicability.

- Saves time: Standing seam roll forming machines can quickly and efficiently manufacture large quantities of metal panels, thus shortening production cycles and helping complete projects on schedule.

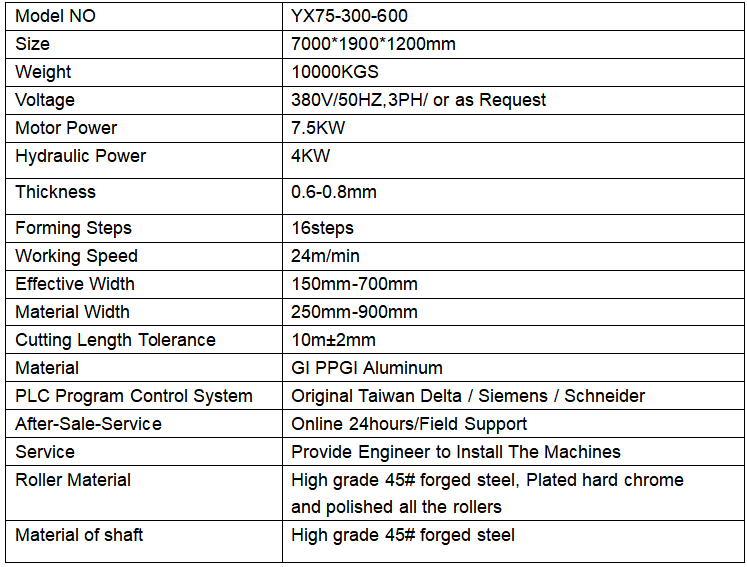

PRODUCT DESCRIPTION