Introduction

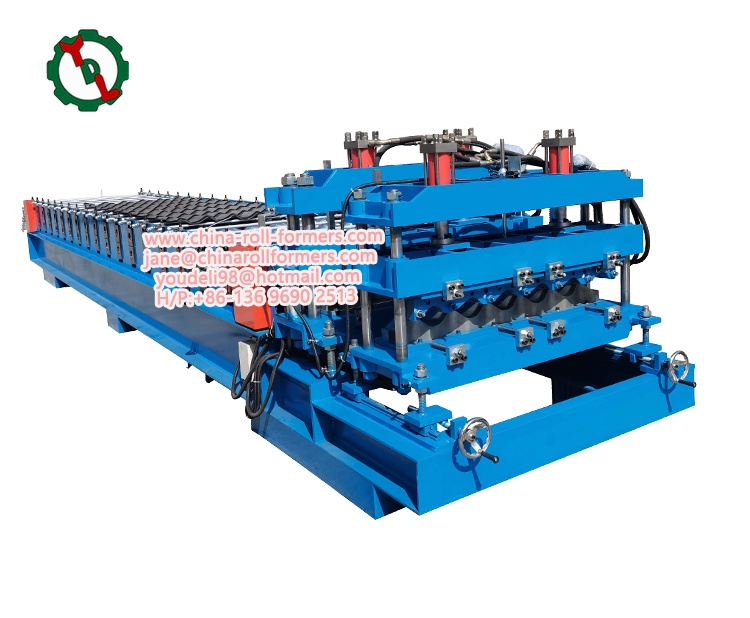

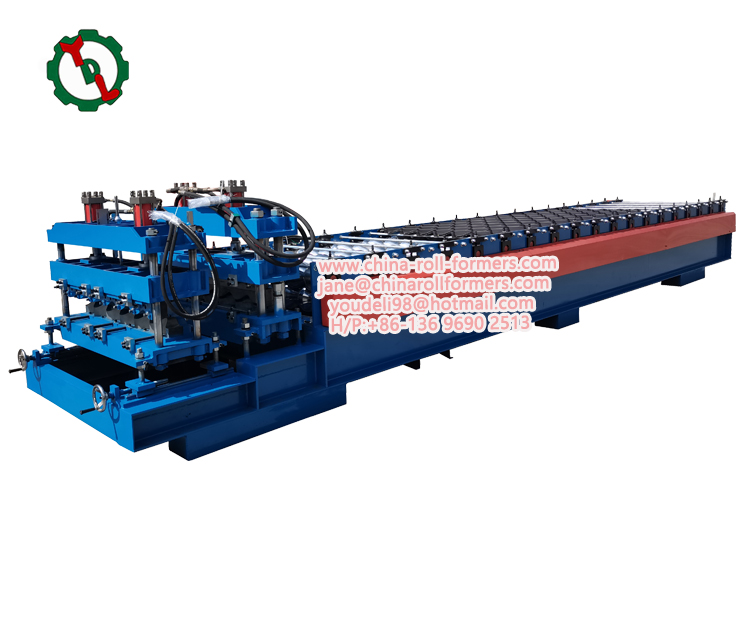

Step Tile Roll Forming Machine is a professional machine used to produce metal roof tiles with stepped patterns. The machine uses advanced roll forming technology to process metal sheets through a series of forming rollers to form roof tiles with regular stepped shapes. This type of tile has excellent waterproof performance and durability, and is suitable for roof decoration in various construction projects. Step Tile Roll Forming Machine can not only improve production efficiency, but also ensure the stability and consistency of product quality. It is one of the indispensable equipment in the modern construction industry.

Features and Advantages of the Step Tile Roll Forming Machine:

Step Tile Roll Forming Machine is a professional equipment for producing metal roof tiles. It has the following features and advantages:

- Efficient production: They can quickly and efficiently produce metal roof tiles of various specifications, greatly improving production efficiency.

- Versatility: The machine can customize roof tiles of different specifications, shapes and lengths according to customer needs to meet various construction needs.

- Automatic control: It adopts advanced PLC control system and touch screen operation interface, which is easy to operate, and the production process can be fully automated, which improves production efficiency and product quality.

- High-precision forming: Through precise roller design and adjustment, Step Tile Roll Forming Machine can produce metal roof tiles with precise size and regular shape, ensuring stable product quality.

- Reliable stability: The machine adopts high-quality materials and strict manufacturing process, with good durability and stability, ensuring long-term stable operation of the equipment.

- Cost saving: Step Tile Roll Forming Machine can reduce labor costs and waste generation, thereby reducing production costs and improving corporate competitiveness.

- Wide application: It is suitable for various construction projects, such as residential, commercial and industrial buildings, etc., providing an efficient and reliable roof tile production solution for the construction industry.

In general, Step Tile Roll Forming Machine is an efficient and reliable metal roof tile production equipment with wide application prospects and market demand.

Roof Tile Roll Forming Machine

The roof tile roll forming machine’s great efficiency and ability to reduce labor expenses and time spent on the job are two of its main benefits. Because of its complete automation, the device can run constantly without requiring human involvement. This guarantees that the manufacturing procedure is quick and effective, improving the machine’s overall output.

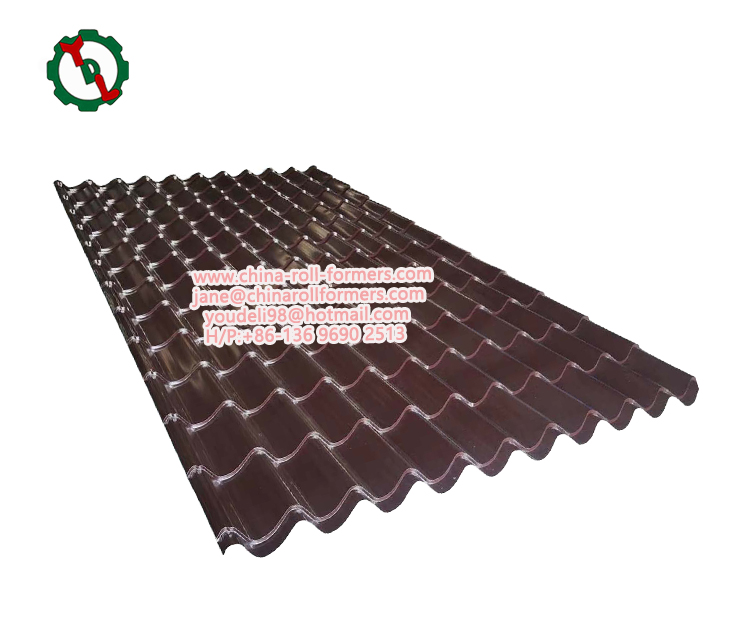

The roof tile roll forming machine creates high-quality tile roofing panels that are resilient to the elements and aesthetically beautiful, in addition to being effective. High-quality components used in the panels’ construction, including galvanized steel, aluminum, and copper, offer great resistance against corrosion and rust.

The roof tile roll forming machine also has the benefit of requiring little maintenance. Because they are constructed with high-quality components and are intended to survive intensive use, the cutting blades and rollers don’t need to be replaced or repaired very often.

The roof tile roll forming machine is a piece of roll forming machinery that is extremely effective, long-lasting, and low-maintenance. It has many advantages, including greater productivity, high-quality output, and no need for maintenance. The Shape Shearing Tile Roofing Roll Forming Machine is the best option if you require a productive and dependable machine to meet your needs for producing roofing panels.

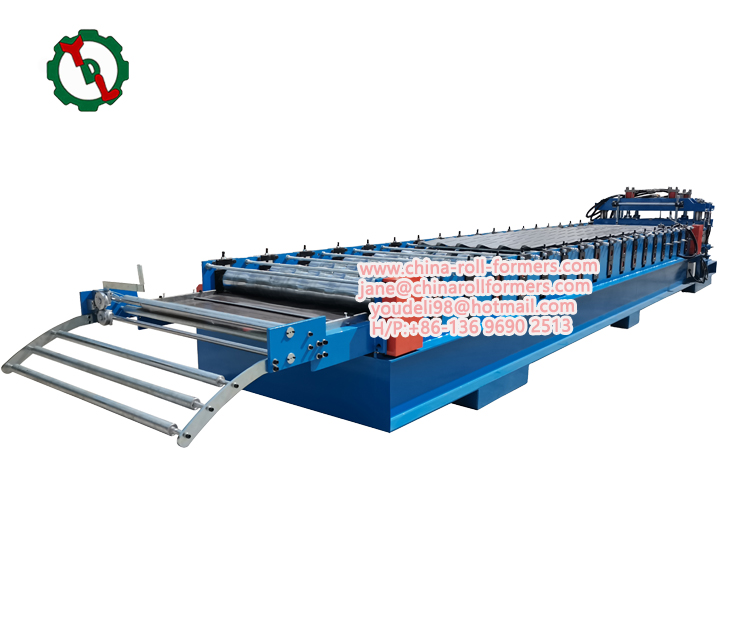

The machine is used to build exterior roofing and wall panels for homes, as well as interior panels or ceilings to improve the look and durability of the roof or walls.

The machine is used to build exterior roofing and wall panels for homes, as well as interior panels or ceilings to improve the look and durability of the roof or walls.

With the development of the computer controller, numerous sets of various data can be set up, making it simple to run, and the machine can adjust the tile length in accordance with the needs. The machinery is automatically adjusted to produce final items of various lengths based on computer data.

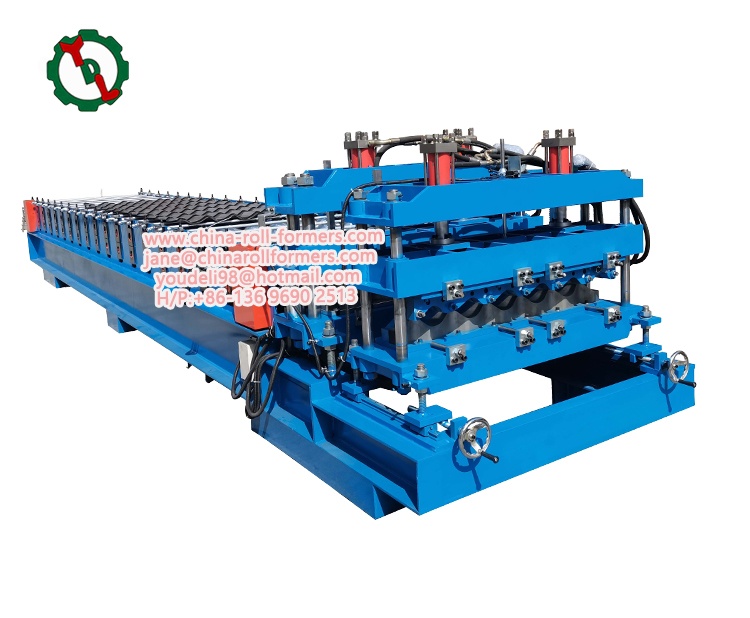

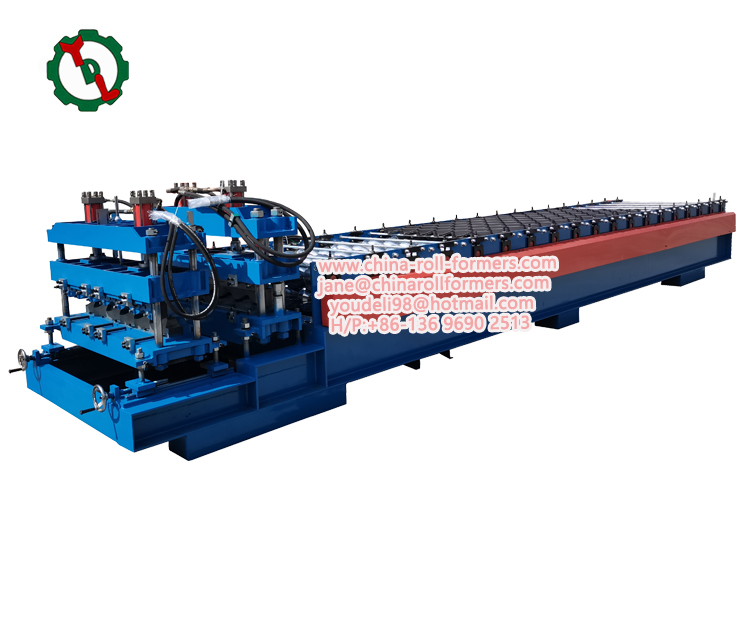

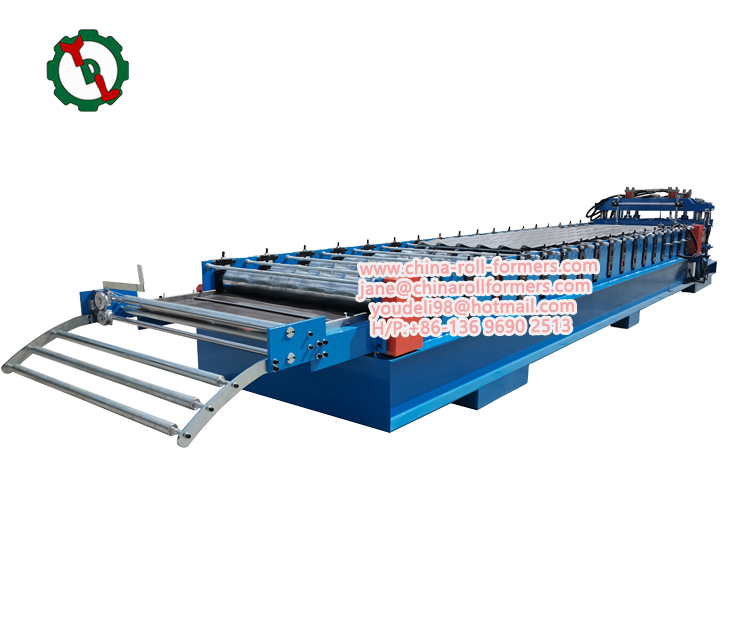

The decoiler, roll forming machine body, hydraulic cutting, PLC control system, main motor, pump station, and receiving table are among the parts of the glazed tile roof roll forming machine.

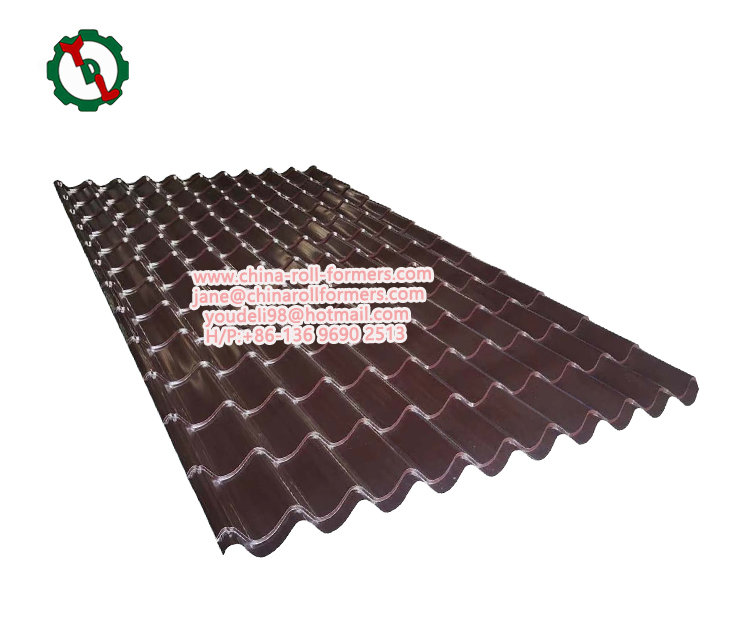

PRODUCT DISPLAY

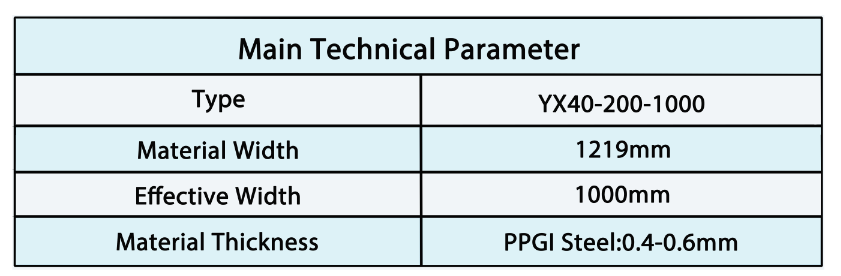

Step tile roll forming machine, glazed tile making machine, and machine for rolling out glazed tiles

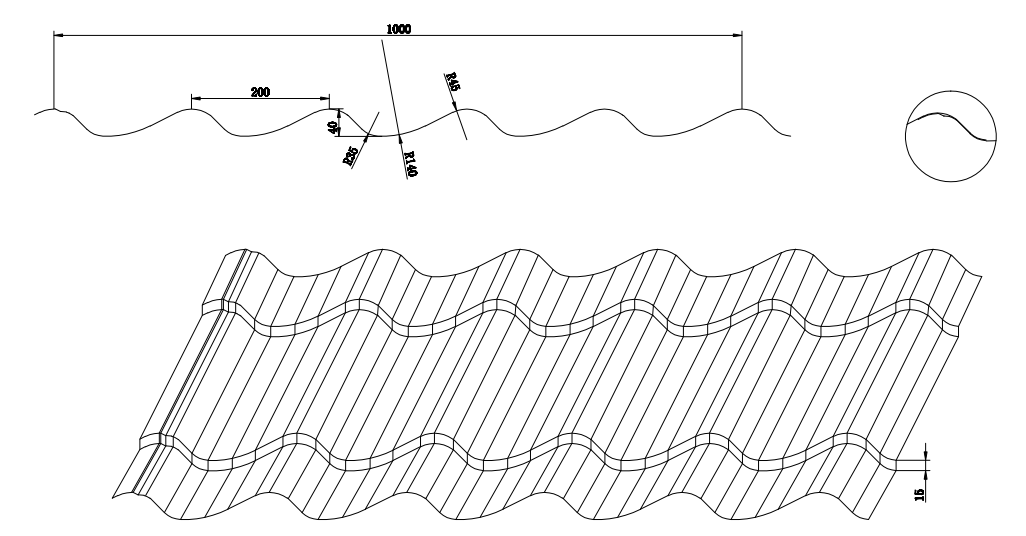

The raw material feeding width for our company’s glazed tile roll forming machine is 1000mm/1200mm/1250mm/1220mm, and the material is PPGI/GI, with a thickness that is always between 0.3 and 0.8. We export our machines to countries around the world, including India, South Africa, Pakistan, Brazil, and others, and we can also make other roof sheet roll forming machine widths to suit your needs.

Shape Shearing Tile Roofing Roll Forming Machine: A New Technology in Roofing Industry

The roofing industry has been revolutionized by the latest addition to its machinery – the Shape Shearing Tile Roofing Roll Forming Machine. With an aim to meet the changing demands of consumers, companies in this industry are constantly looking for innovative ways to manufacture roofing materials. This new technology uses advanced roll forming techniques to create roofing materials with a unique and aesthetically pleasing appearance. The machine is capable of producing tiles of different shapes and sizes, giving homeowners a wide range of options to choose from for their homes.

What sets this technology apart from others is its shearing station, which allows for precise shaping and cutting of tiles to ensure that they fit perfectly and are resilient. Its focus on water resistance and durability is crucial, as poorly cut tiles can easily damage the overall roofing structure. Not only is this roll forming machine efficient and cost-effective, but its output is also environmentally friendly. The tiles produced by this machine are made of high-quality materials, designed to withstand even the harshest weather conditions.

Manufacturers have reported a significant decrease in waste and labor costs since implementing this technology into their production processes. The Shape Shearing Tile Roofing Roll Forming Machine is automated, speeding up the production process and increasing overall efficiency. As a result, roofing companies can provide more options for consumers to choose from while improving upon the quality of the products that they produce.