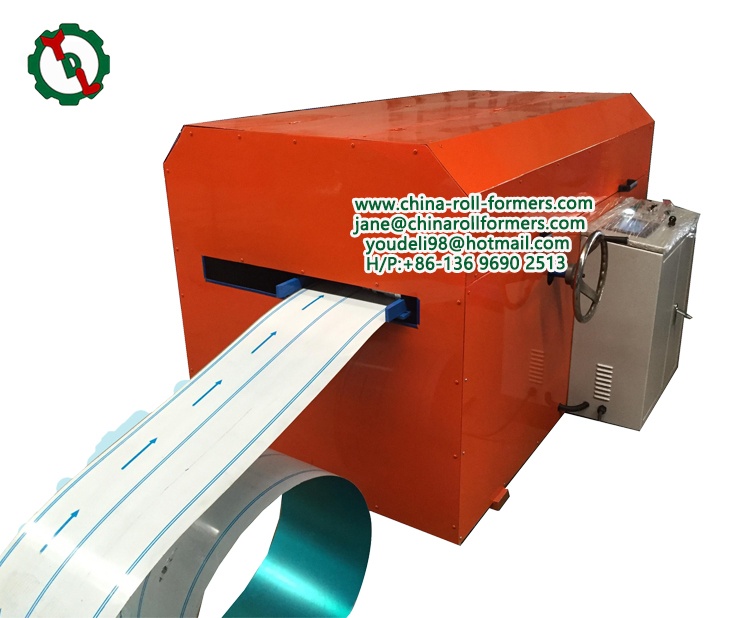

The Automatic Portable Vertical Seamless Panel Machine is a versatile piece of equipment that features portability, automation, and efficient production, making it ideal for the creation and construction of structures requiring seamless panels. This portable standing seam panel machine of our company is a highly portable and automated equipment, dedicated to making seamless panels. This machine combines advanced technology with portability and is designed to provide users with efficient panel manufacturing solutions.

Characteristics

- Automation: Automatic control system, users can easily control production process.

- Customization: The device can also create seamless panels in a variety of sizes and shapes. Additionally, the panel can be modified to meet certain customer needs.

- Portability: This machine has a compact design with wheels and handles for easy portability and movement. It can be moved from one location to another with ease, making it ideal for construction projects that require regular movement.

- Efficient production: Thanks to automated control and high-precision manufacturing processes, the machine is able to produce high-quality panels quickly and accurately, increasing productivity.

- Easy maintenance: The machine is also easy to use and maintain, reducing the likelihood of downtime due to malfunctions throughout the production process.

Parameter

- Size:2000*1200*1200mm

- Weight:1100KGS

- Voltage:380V/50HZ/3PH

- Motor Power:2.2KW

- Hydraulic Power:2.2KW

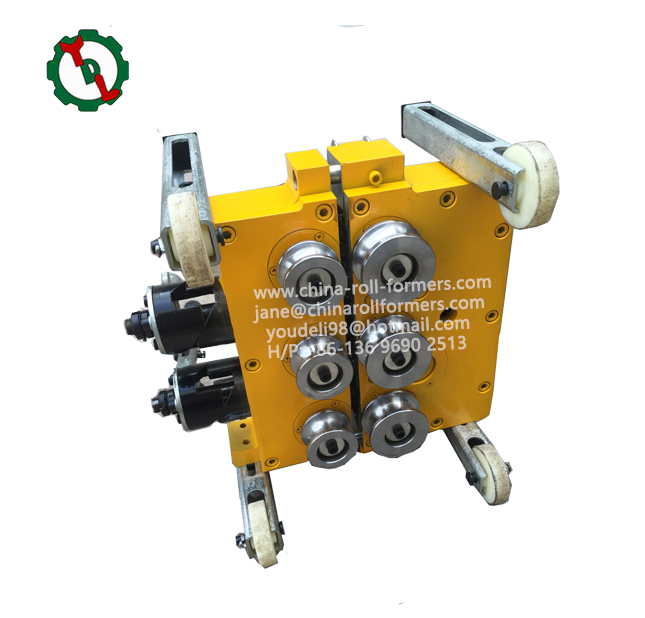

- Forming Steps:6steps

- Forming Steel Thickness:0.5-0.8mm

- Forming Aluminum Thickness:0.7-1.0mm

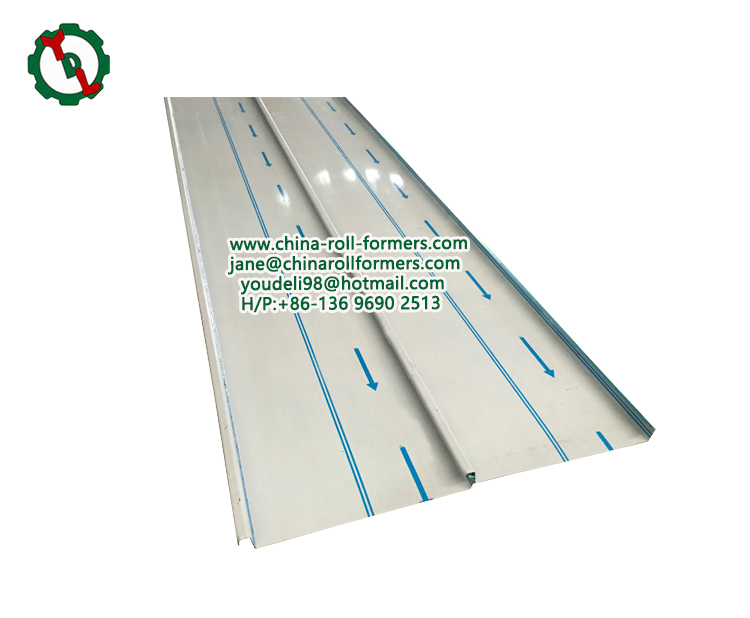

- Height of Roofing:25mm

- Effective Width of Roofing:200mm – 530mm

- Material Width:280mm – 610mm

- Tolerance:±2mm

- Roller material: High grade 45# forged steel, Plated hard chrome and polished all the rollers

- Material of principal axis:High grade 45# forged steel

- After-sales Service Provided:Engineers available to service machinery overseas

applications:

Automatic Portable Vertical Seamless Panel Machines are suitable for construction projects that require unique form and shape, as they can be customized according to the specific requirements of the customer. It can be applied to tasks such as constructing prefab homes, storage facilities and commercial buildings. Thanks to its versatility, it can be used in on-site and off-site construction projects. The machine is capable of producing a variety of panels including wall, roof and floor panels.

The workflow of portable standing sewing machine

The manufacturing process of portable standing stitch machines is automated, and the operation of the machine can be monitored and adjusted through a control panel or computer interface. Youdeli’s portable standing seam machines manufacture standing seam panels efficiently and accurately, making them suitable for a variety of construction applications. The working principle of our machine is as follows:

Material preparation: First, the roofing or wall covering material needs to be prepared, usually a metal coil or other suitable sheet. These materials are then loaded onto the machine, ready to go to the next stage.

Feed Material: The material is fed into the feed system of the portable standing seam machine. Typically, this system includes a roller that guides the material and ensures that it is in the correct position within the machine.

Forming the standing seam: Once the material is fed into the machine, it passes through a series of rollers and dies. The role of these rollers and dies is to bend and shape the material to create the desired standing seam. This step often requires high precision and pressure.

Cutting: After the standing seam has been formed, the machine is usually equipped with a cutting device. This cutting unit cuts the material to the desired length on demand to fit specific roof or wall dimensions.

Output products: After forming and cutting are completed, the standing seam panels are sent to the discharging system and discharged from the machine’s discharging port, ready for roof or wall installation.