A portable standing seam machine is a piece of equipment used to make standing seam shingles on metal roofs or walls. This KLS25 portable standing seam machine manufactured by our company has a light and compact design, which makes it easy to carry and use in different job sites. Their main function is to convert metal coil or sheet through a series of processing steps into roof or wall cladding panels with standing seam characteristics.

The portability of the KLS25 Portable Stand Seamer makes it suitable for a variety of different construction projects and maintenance jobs. They can be rapidly deployed to sites where metal roofs or walls need to be fabricated or repaired, and produce sheet metal with standing seam characteristics in a short period of time. These machines are invaluable for tasks that require fast, efficient, and high-quality metal roofing fabrication and maintenance.

Main components of portable stand-sewing machine

- Coil Feeding System: This is the part that introduces the metal coil into the machine for subsequent processing. A coil feeding system usually includes a coil device, guide and tension control to ensure that the coil remains smooth and stable during processing.

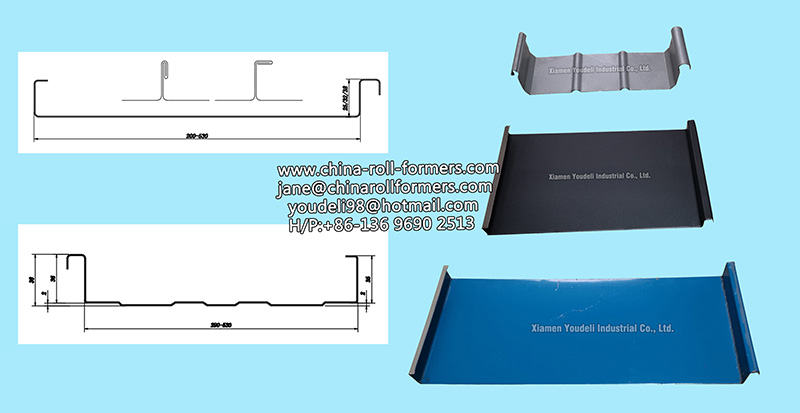

- Roll forming system: This is the core part of the standing seam machine, including a series of rolling rollers. These rolls apply pressure and bend the metal to form the flat sheet material into specific contours with standing seams. The design of the roll forming system determines the final roof or wall panel shape and standing seam specifications.

- Cutting system: Once the metal material has been roll formed, the cutting system cuts it to the exact length required to create panels with the correct dimensions.

- Control system: Portable standing seam machines are usually equipped with a control panel or computer numerical control (CNC) system to monitor and adjust the operation of the machine to ensure that high-quality panels are produced.

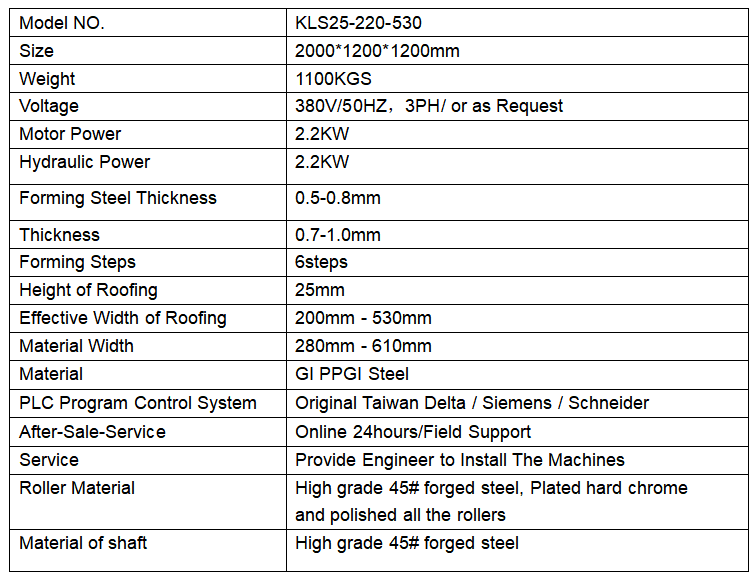

PRODUCT DESCRIPTION

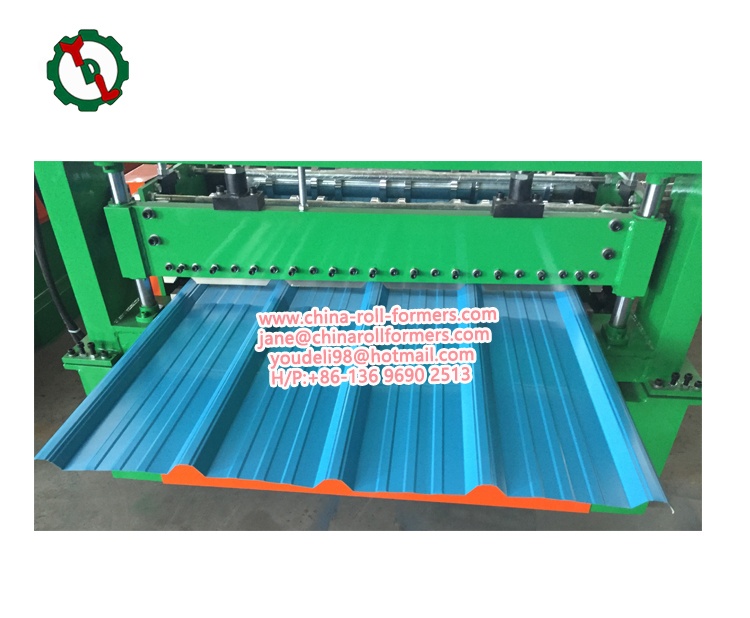

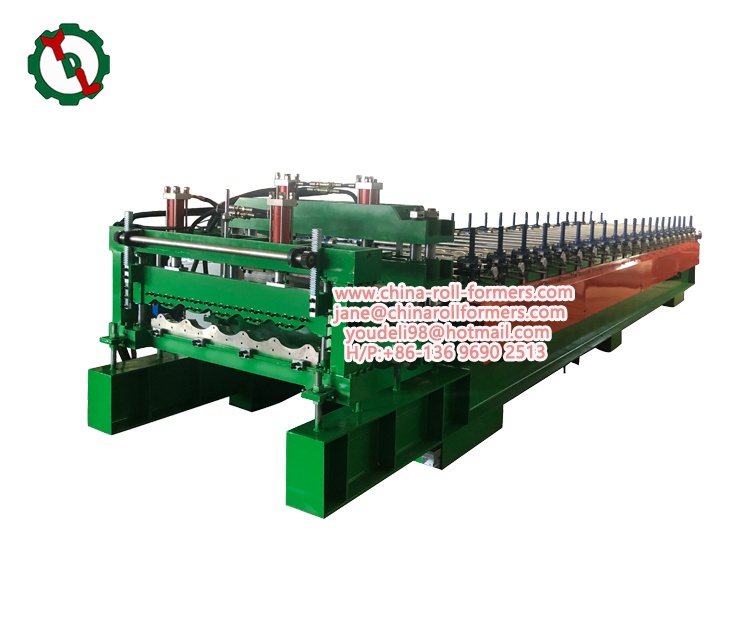

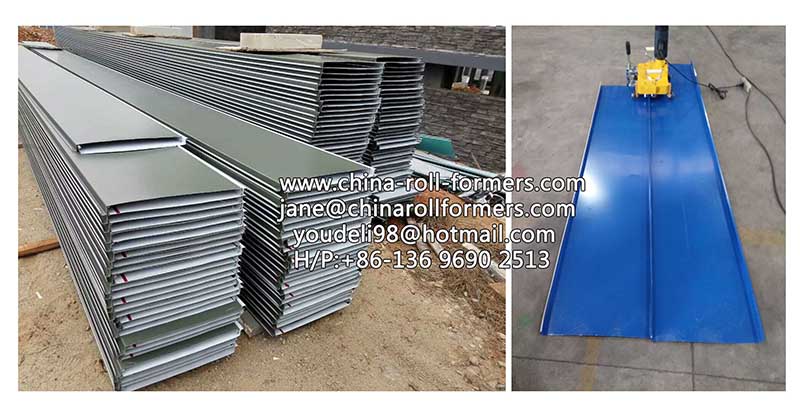

PRODUCT DISPLAY

CERTIFICATE

Working principle of Portable Standing Seam Machine

A common option for roofing applications on both commercial and residential structures is the standing seam roof system. Long, straight panels with elevated interlocking seams that extend vertically up the roof are what give it its distinctive appearance. These roofs are sleek and contemporary and offer good wind resistance. A portable standing seam machine, a specialized piece of machinery used to bend the metal roof panels into the necessary forms for placement on a roof, is used to produce the standing seam roof. This article examines how a portable standing seam machine operates.

What is a Portable Standing Seam Machine?

A hydraulically powered tool called a portable standing seam machine is used to form and crimp roofing panels locally. It is made up of a number of parts, including the power supply, shear, forming and crimping rolls, and hydraulic control system. Compact and light in weight, portable standing seam machines are simple to move from one location to another.They can be swiftly set up on a flat surface and have a relatively small footprint.

Working Principle

The feeding stage, the shaping stage, and the crimping stage are the three phases that make up a portable standing seam machine’s operation.

Feeding Stage

In the feeding step, the desired roofing material’s metal coil is loaded into the machine and fed through it at a predetermined pace. Depending on the desired panel width, the operator changes the spacing between the forming rolls before manually feeding the coil into the machinery.

Forming Stage

In order to protect the material from roller scratches during the feeding stage, protective coatings must also be applied. In the forming stage, the metal coil is worked with forming rolls to create the standing seam profile.

The forming rolls are propelled by a hydraulic system, which bends the metal to the required angle and shape. Depending on the required standing seam shape, the forming rolls’ profiles can be modified.

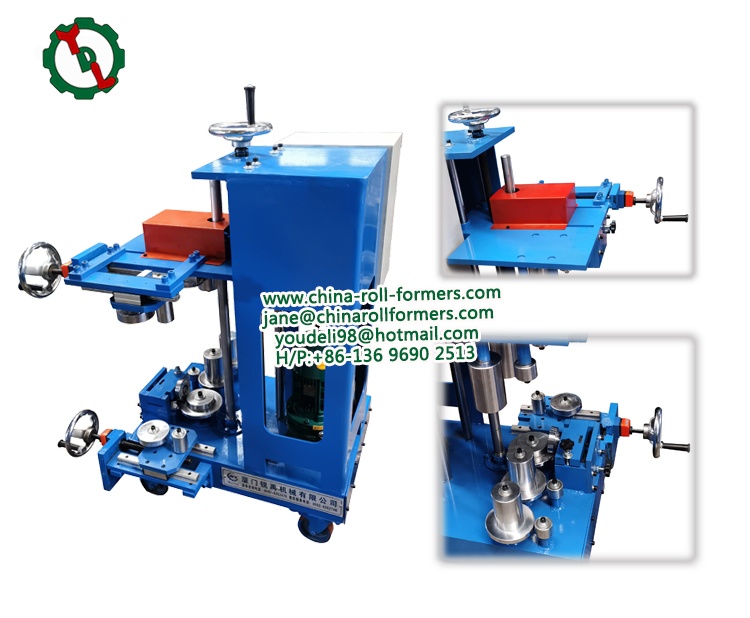

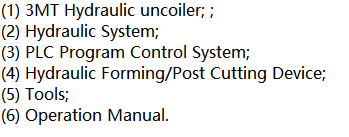

ACCESSORIES

CUSTOMER ENGINEERING

Crimping Stage

The two panels are interlocked together, and any gaps between them are sealed using a crimping roller during the crimping stage. The raised seams that distinguish standing seam roofs are also produced by hemming rollers. Advantages of Portable Vertical Seaming Equipment High productivity, cost-effectiveness, and flexibility are just a few of the advantages that portable vertical seaming machines provide. Here are some of the benefits of using the device:

- Higher efficiency: the standing seam machine can quickly produce roof panels, reducing labor costs and project duration.

- Cost Efficiency: By using a standing seam machine, there is no need to contact suppliers for prefabricated panels, which reduces shipping and handling costs.

- Flexibility: Portable standing seam machines can be used to make panels on site, enabling more precise measurements and customization.

A portable standing seam machine is a vital piece of equipment for roofing contractors who need to produce standing seam panels on site. The basic operation of these machines consists of three processes of feeding, forming and curling. These machines offer a number of benefits including increased flexibility, cost-effectiveness and efficiency. The success of any roofing project depends upon selecting the ideal standing seam machine.

AXES AND ROLLERS

RELATED MACHINERY

PRODUCT STRUCTURE FEATURES

- Strict material selection: stringent installation requirements, meticulous material selection, and a refusal to cut corners.

- Simple operation: it’s simple to set up, operate, and utilize.

- Consistent performance: solid structure, well-developed technology, and a long service life.

- Stable operation: The application of mature technology in conjunction with the current state of domestic and international manufacturing.

CARGO LOADING