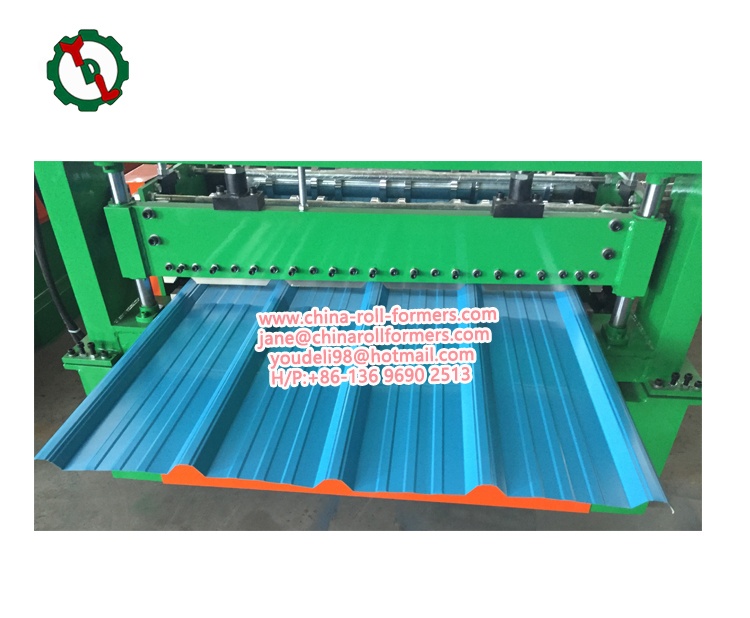

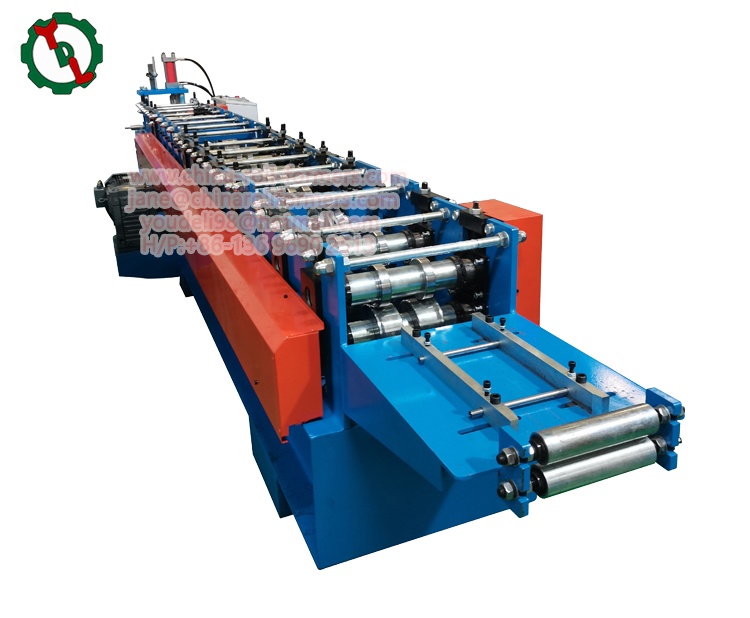

The double layer roll forming machine is ideal for producing metal roof panels, wall panels, and other custom metal profiles. With its advanced technology and dual-layer design, it can significantly increase production efficiency and reduce labor costs.

One of the key features of this machine is its versatility. It can easily switch between different profile types and sizes, making it perfect for small batch production or large-scale projects. The double layer design allows for continuous production without the need to stop and change the forming rollers, saving you time and effort.

In addition to its efficiency, this roll forming machine is also built to last. Constructed with high-quality materials and precision engineering, it can withstand the rigors of continuous use and deliver consistent results. This durability ensures that your investment will last for years to come, providing a reliable and cost-effective solution for all your metal forming needs.

Another benefit of the double layer roll forming machine is its ease of use. With intuitive controls and user-friendly interface, operators can quickly learn how to operate the machine and start producing high-quality metal profiles in no time. This ease of use can help to minimize training time and ensure that your production runs smoothly from the start.