L angle steel forming machine is a computer-controlled hydraulic roll forming machine, which is mainly used to form high-strength steel into the required profile. It can manufacture L angle irons of different lengths and thicknesses. L angle steel is a shape like Structural steel with L and right angles is mainly used for frame and support in various industries such as construction and manufacturing. The bending process adopted by the angle steel roll forming machine produced by our company can be applied to different types of steel materials, and we can meet the individual needs of customers.

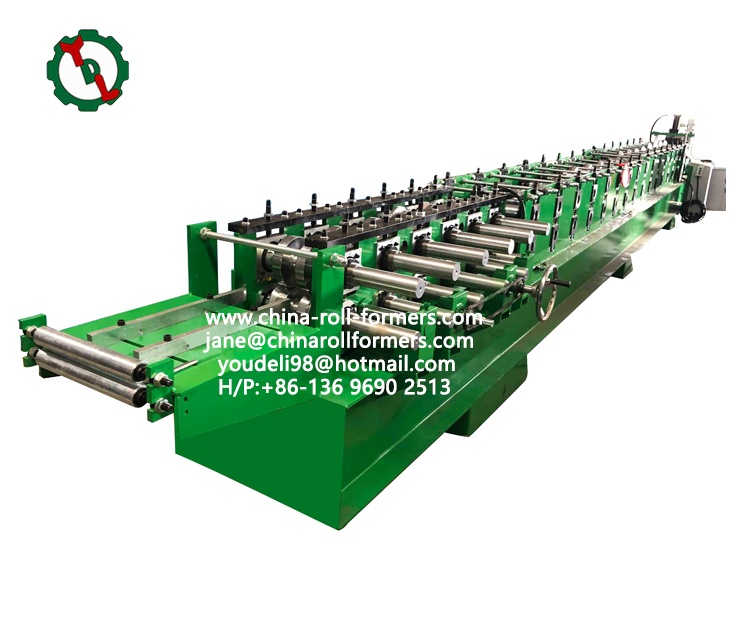

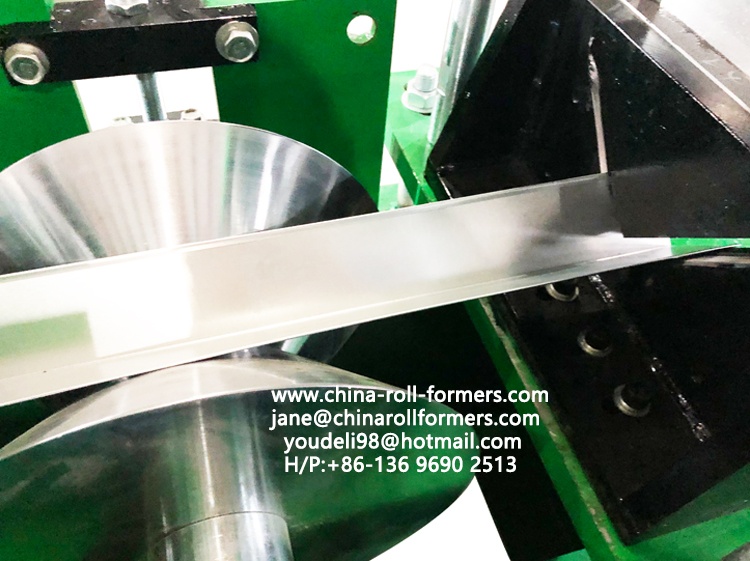

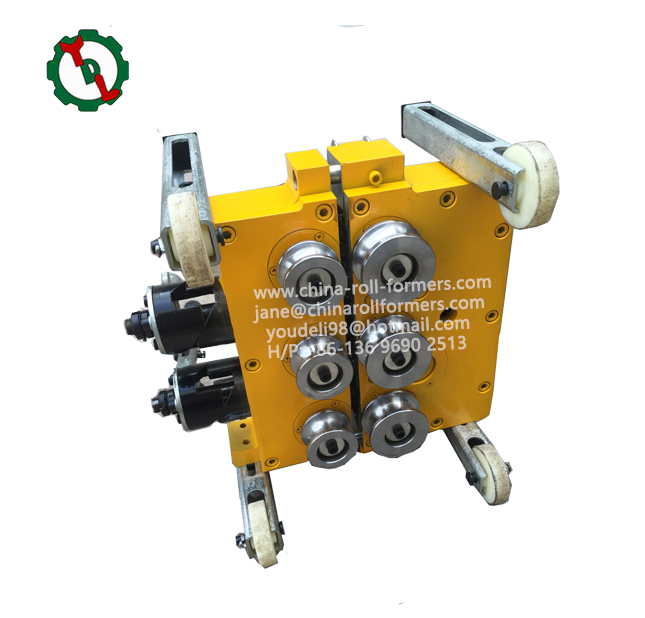

L angle steel roll forming machine is composed of several parts such as uncoiler, feeding system, punching system and cutting system. The uncoiler is used to uncoil the steel coil and feed it into the machine. The feeding system ensures that the steel passes through the machine smoothly and accurately. Punching systems are used to punch holes or grooves in steel as required. The cutting system is responsible for separating the finished L angle iron from the remaining coils.

In addition to precision and versatility, L angle iron forming machines are also highly productive. It can produce large volumes of L Angle Iron quickly and efficiently, which is essential for companies with high demand. In addition, the machine is designed to optimize material usage and minimize waste. This is very important for companies trying to reduce the costs associated with material waste.

Main Technical Parameter

| No | Item | Data |

| 1 | Model NO. | L25-75 |

| 2 | Size | 10000*1000*1200mm |

| 3 | Weight | 4000KGS |

| 4 | Voltage | 220V/60HZ/3PH |

| 5 | Motor Power | 5.5KW |

| 6 | Hydraulic Power | 2.2KW |

| 7 | Forming Steps | 21 |

| 8 | Working Speed | 25m/min not including cutting |

| 9 | Size of L Angle | 25mm to 140mm |

| 10 | Feeding Material Width | 50mm to 305mm |

| 11 | Thickness | 0.3-1.0mm |

| 12 | Cutting, Forming Tolerance | ±2mm |

Master Diagram

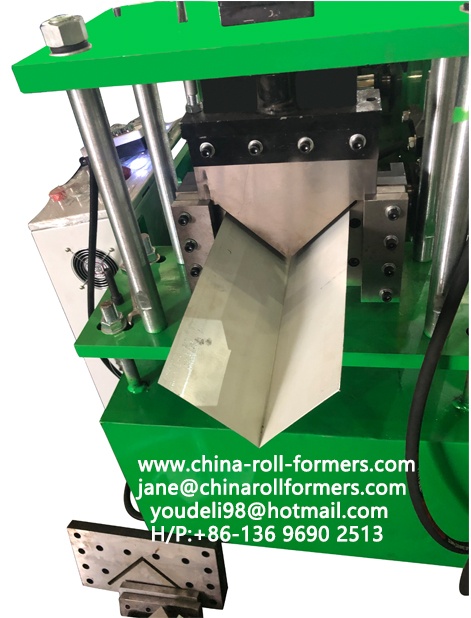

L angle iron forming machine is a crucial equipment in the manufacturing industry. It is used to create L-shaped metal products with high accuracy and precision. The machine is designed to bend and shape flat metal sheets into a right angle, and can be set to any angle between 0 and 180 degrees. This makes it a versatile piece of equipment that can be used for a variety of applications, such as creating metal frames and supports, as well as the fabrication of metal roofs and wall cladding.

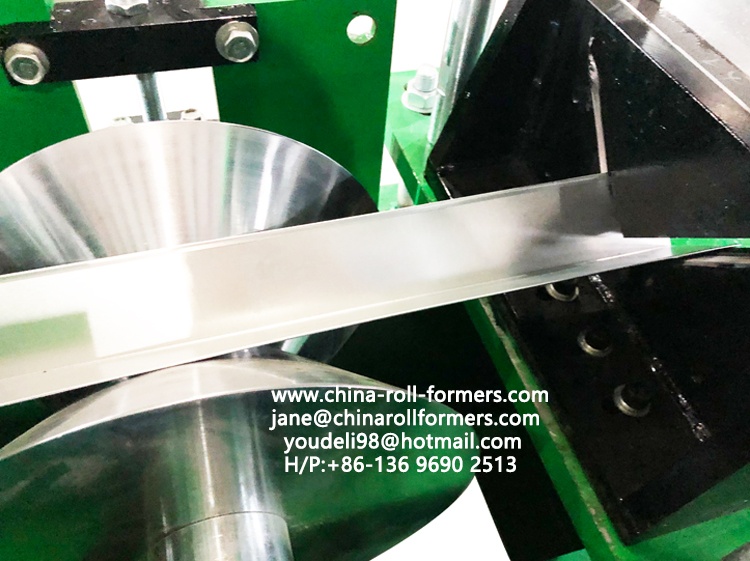

The L angle iron forming machine is typically made up of two main components: the roller and the hydraulic system. The roller is responsible for bending the metal sheet, while the hydraulic system controls the force applied to the roller. The size of the machine can vary depending on the application, but typically ranges from small, bench-mounted units to large, industrial-sized machines. The machine can also be equipped with various additional features, such as digital readouts, back gauge systems, and safety guards.

One of the main advantages of the L angle iron forming machine is its accuracy and consistency. The machine can bend metal sheets to within a fraction of a degree, ensuring that the final product is of the highest quality. This makes it ideal for use in the production of high-precision engineering components, where accuracy and consistency are critical.

Another advantage of the L angle iron forming machine is its efficiency and productivity. The machine can bend large quantities of metal sheets quickly and easily, reducing production time and increasing productivity. This makes it an essential piece of equipment in high-volume manufacturing settings, where speed and efficiency are key.

n addition to its accuracy and productivity, the L angle iron forming machine is also highly versatile. It can be used to create a wide range of L-shaped metal products, from simple brackets and supports to more complex structural components. This makes it an ideal piece of equipment for a variety of industries, including construction, automotive, and aerospace.

The L angle iron forming machine is also highly economical. With low maintenance costs and high durability, the machine can provide a cost-effective metal shaping solution for many years. This makes it a valuable investment for any manufacturing business, regardless of size or industry.

Axes and rollers

Related Machinery

Our advantage

Cargo Loading