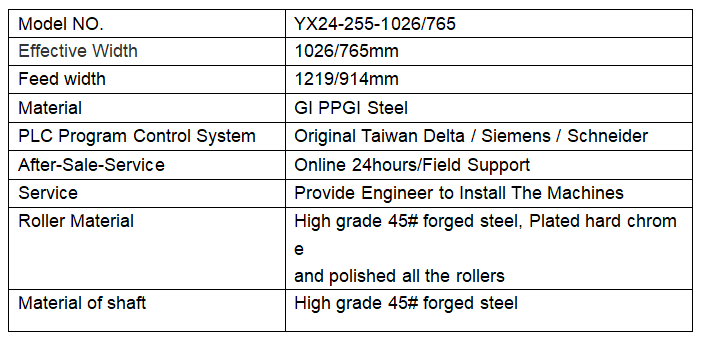

Working principle of the machine

Trapezoid Rib Roofing Roll Forming Machine, which is Trapezoid Rib Roofing Roll Forming Machine, is frequently produced using corrugated roll forming machines. These machines mold flat metal into a corrugated, wave-like form using a succession of rollers.

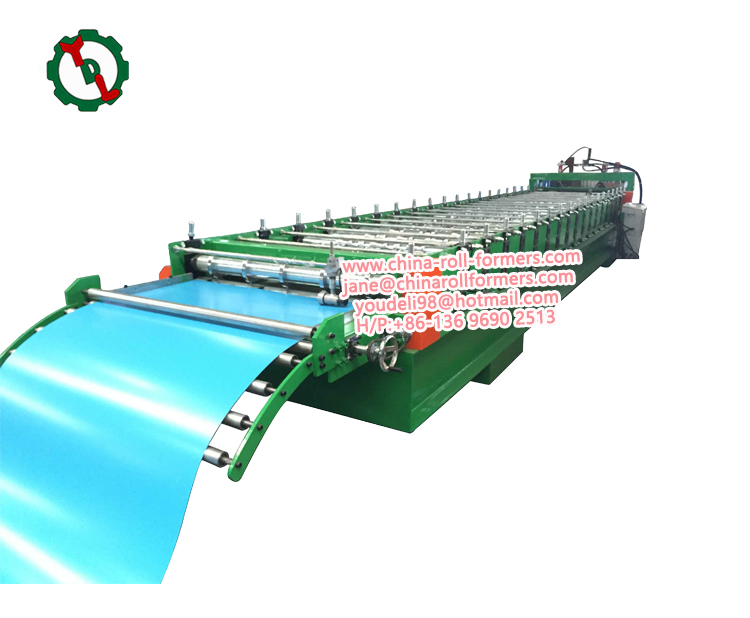

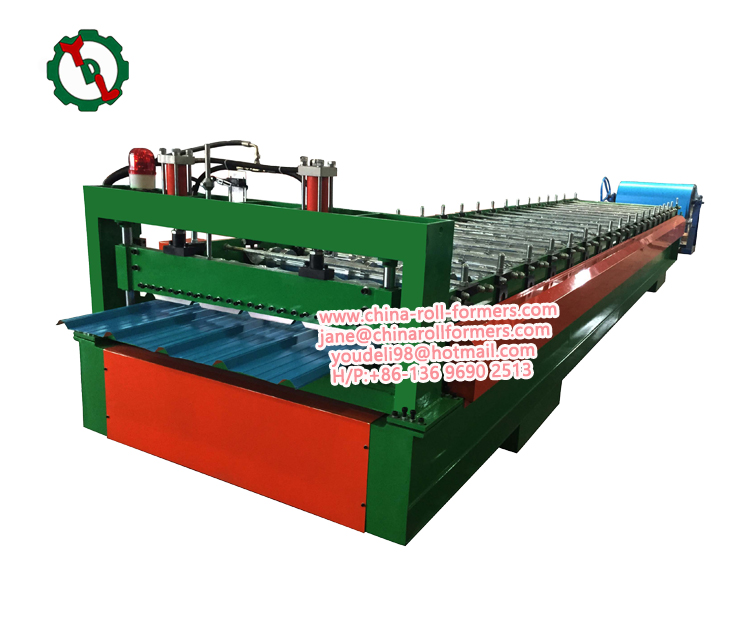

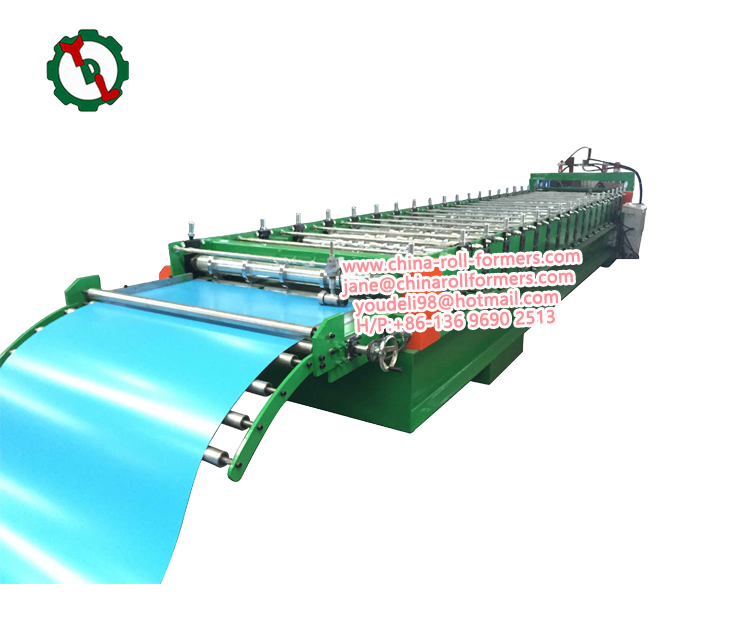

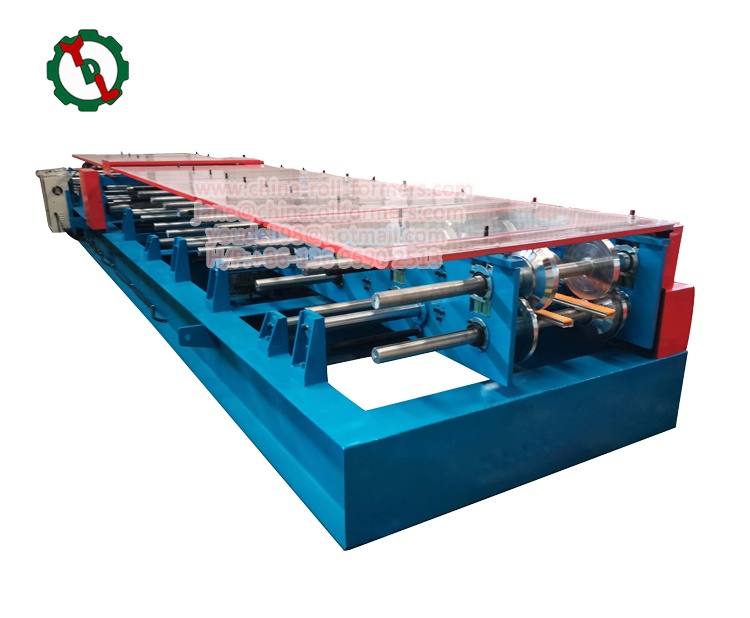

The essential components of a corrugating machine are an uncoiler, a feeding device, a shaping machine, a cutting device, and a stacking system. A coil of metal is first supplied into the uncoiler, and the uncoiler then feeds the metal into the roll forming machine through the feeding device.

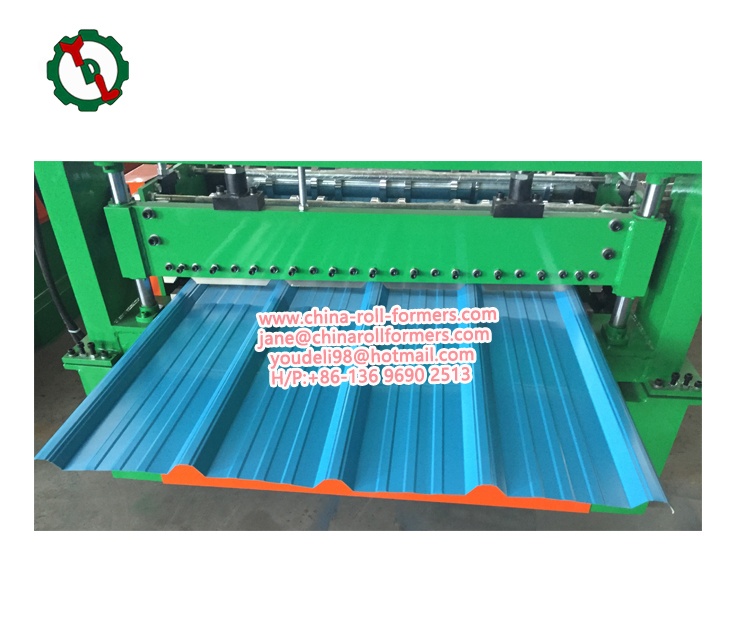

A roll forming machine’s several rollers progressively bend and shape the metal. As it travels through the machine, the metal becomes a corrugated profile. By varying the number of rollers and their spacing, several corrugated profiles may be generated.

Advantages of trapezoid rib roof roll forming machine

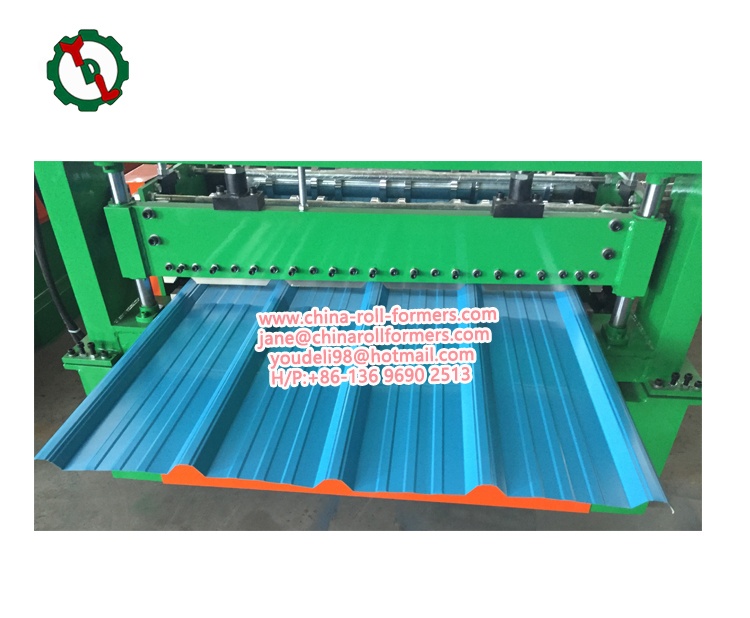

- Our equipment is very efficient and can produce large quantities of roof panels quickly. They are also dimensionally precise, ensuring a constant and uniform profile for each roof or wall panel.

- trapezoid rib roll formers are capable of fabricating panels from a variety of materials, including galvanized steel, aluminum and stainless steel. Therefore,

- our company is able to offer its customers various solutions depending on your requirements.

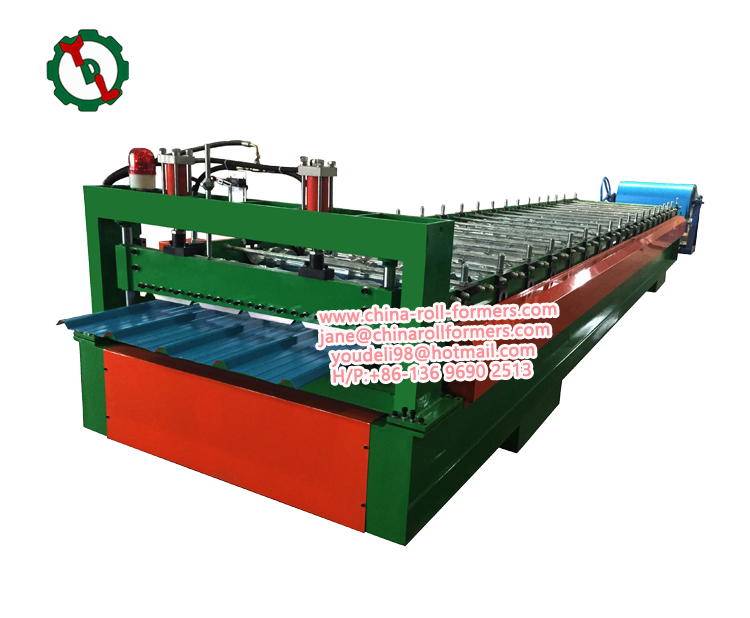

- Trapezoid rib sheets are a great choice for roofing and siding applications for construction projects because they are lightweight, yet strong and durable. They require little maintenance and have a very long service life.

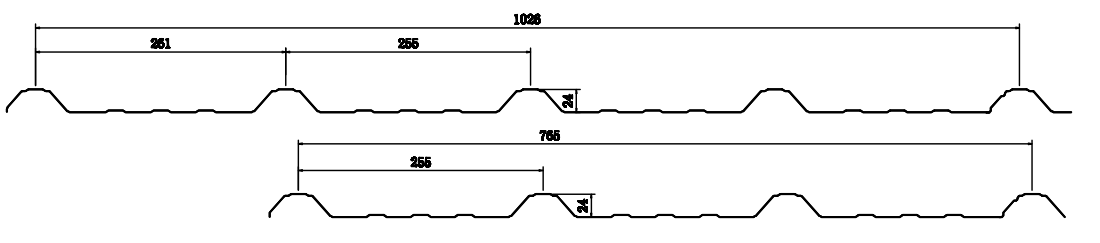

We can manufacture trapezoid rib roof sheets according to your usage specifications, and the plate shape can also be designed and customized according to your needs. Our company is a professional manufacturer of roofing roll forming machines, which can meet your customized needs, and our factory has more than ten years of experience in mechanical production, which can meet your requirements.

Galvanized roof sheet roller machine high speed trapezoid rib roof sheet press machine has several significant advantages:

Galvanized roof sheet roller machine high speed trapezoid rib roof sheet press machine has several significant advantages:

Customization accepted, high precision and high speed: This machine can be customized according to the specific needs of customers to ensure the production of corrugated metal roof panels with high precision and high speed. No matter what specification and size of roof slab you need, we can meet your requirements.

Fully automatic computer control, easy to operate: the machine adopts fully automatic computer control system, which is very convenient to operate. This means operators can easily set up and monitor the operation of the machine, ensuring stable and efficient production processes.

HIGH QUALITY MATERIALS AND PRECISION MANUFACTURING: This machine’s rolls and shafts are manufactured with precise specifications and controls to ensure their durability and stability. The drum material is heat-treated with CR12 MOV, and the heating temperature is strictly controlled and can be in the range of 58°C to 62°C, which helps to improve the durability and quality of the product.

This galvanized roof sheet roller machine high speed trapezoid rib roof sheet press machine from youdeli not only has a high degree of customization performance, but also has an advanced fully automatic computer control system and high-quality manufacturing materials to ensure the quality and longevity of the product. These advantages make it an ideal tool for the manufacture of corrugated metal roof panels, capable of meeting high-precision and high-efficiency production demands.

This galvanized roof sheet roller machine high speed corrugated metal roof sheet press machine from youdeli not only has a high degree of customization performance, but also has an advanced fully automatic computer control system and high-quality manufacturing materials to ensure the quality and longevity of the product. These advantages make it an ideal tool for the manufacture of corrugated metal roof panels, capable of meeting high-precision and high-efficiency production demands.

Our company advantage

- Effective quality control

- Extremely aggressive pricing

- Cutting-edge technology products

- Top employees for lifestyle consumer electronics professionals.

- Effective communication

- Reliable OEM&ODM support

Device composition:

Man-made uncoiler, molding machine, computer control system, hydraulic control system, cutting.

The products are widely used in the manufacture of various industrial plants, civil buildings, warehouses and simple steel structure buildings, with the characteristics of beautiful appearance and durability.

- Good carrying capacity: it has the advantages of easy operation and maintenance, and easy replacement of molds

- Its components include: mainly composed of loading rack, feeding platform, upper computer control box and so on

- Stable structure: automatic control software is adopted to realize software to realize production information management

- Excellent selection of materials: various hidden roof panels produced by this machine solve the problem of leakage of conventional series roofs。