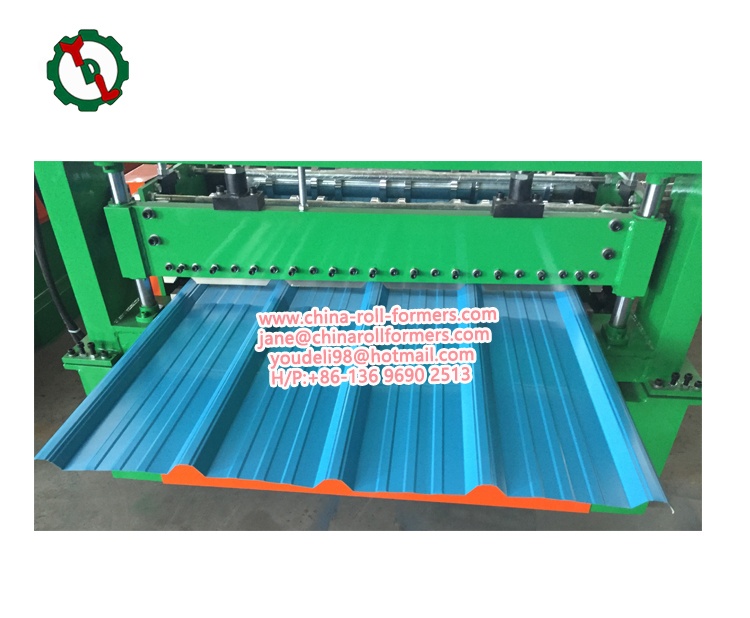

- Roofing Sheet Roll Forming Machine

A ground-breaking device that has revolutionized the global roofing business is the roofing sheet roll forming machine. The device use cutting-edge technology to create roofing sheets of the highest quality that are robust, corrosion-resistant, and available in a range of dimensions.

A highly educated and skilled group of engineers work to assure the precision and accuracy of the roofing sheet by operating the roll forming equipment for roofing sheets. This guarantees that each sheet generated is of a high level and adheres to the necessary requirements.

To enable the production of various roofing sheets, including corrugated, trapezoidal, IBR, and standing seam roofing sheets, the machine also includes a variety of different molds and equipment.The cost reductions that using a roofing sheet roll forming machine offers is one of its major advantages. The machine uses automated technologies to operate, which removes the need for a sizable crew and significantly lowers labor expenses.

The machine's operation speed is an additional benefit. It can quickly generate large quantities of roofing sheets, guaranteeing that deadlines are completed on time.

The roofing sheet roll forming machine is also eco-friendly because it generates less trash during production, minimizing its negative effects on the environment.