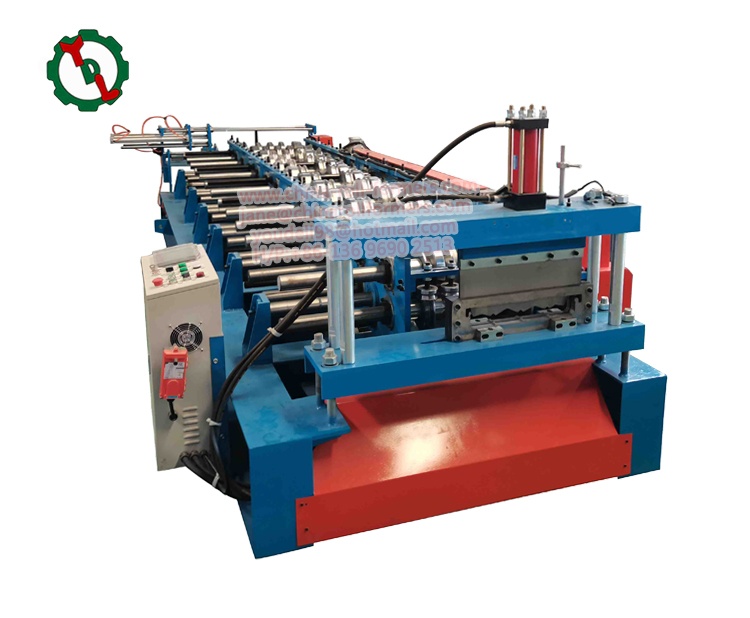

- 65MM Standing Seam Roofing Machine

This machine is easy to install and can be set up in a short period of time. It is also compact and can be easily moved from site to site. It is made of high-quality materials that ensure long-lasting durability, and all parts and components are sourced from reputable suppliers.

The Metal Roof Tile Making Panel Standing Seam Roll Forming Machine is an indispensable machine for anyone in the metal roofing industry. It is efficient, reliable, cost-effective and easy to use, and is capable of producing high-quality metal roof tiles and panels with a standing seam that meet the requirements of any roofing project.

The Metal Roof Tile Making Panel Standing Seam Roll Forming Machine is designed for ease of use and is user-friendly. It comes with an easy-to-use control system that allows operators to set parameters for each of the profiles they want to create. This machine also has an automatic lubrication system that ensures smooth and efficient operation, reduces wear and tear and increases longevity.

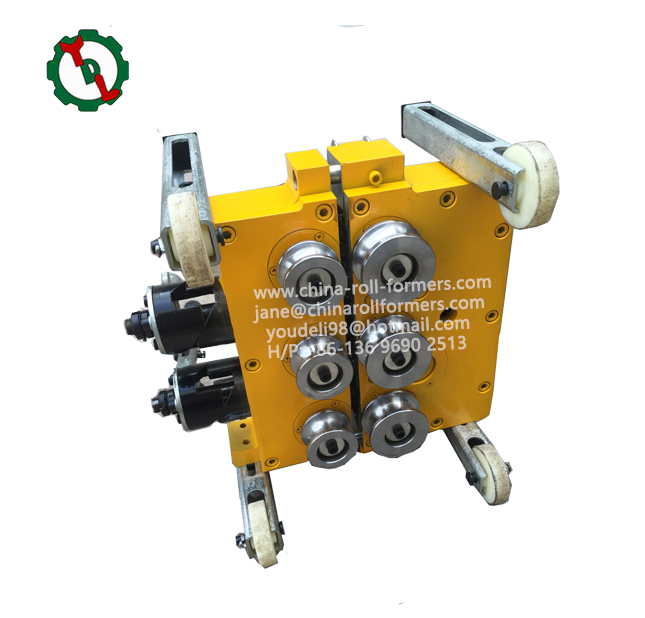

The standing seam profile produced by this machine is ideal for roofing applications, as it creates a strong and watertight seal that is easy to install and maintain. The machine can produce standing seam panels of various widths and spans, making it suitable for both residential and commercial roofing applications.

The Metal Roof Tile Making Panel Standing Seam Roll Forming Machine is a high-quality and efficient machine that is perfect for those who want to roll form metal roof tiles and panels with a standing seam. This machine is designed to produce a range of metal roof tiles and panels of different sizes and thicknesses with ease and precision.

The machine has a number of impressive features that make it stand out from the crowd. It is powered by a robust motor that is reliable and durable, and can roll form metal sheets of up to 1.5mm in thickness. The machine has a high-quality roller system that ensures accurate and consistent profile shapes, and a hydraulic cutting system that cuts metal sheets to the required size and shape.