- Door Jamb Machine

First, I need to explain what a Door Jamb Roll Forming Machine is. It's a specialized type of roll forming equipment designed to produce door jambs efficiently. I should mention the materials it works with, like steel, aluminum, or maybe even vinyl, depending on the application.

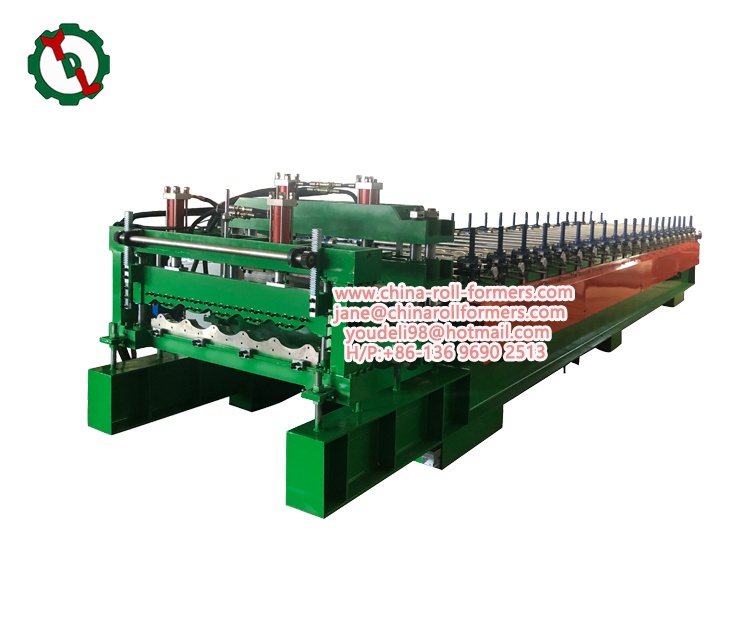

Next, the structure of the machine. Roll forming machines typically have a series of stands, each with rollers that progressively shape the metal. The number of stands can vary, but for door jambs, maybe around 10-15 stands? I should check typical configurations. Also, the machine might include a decoiler for feeding the metal coil, a straightener to flatten the material, and a cutoff system to shear the jambs to length.

Key components are important. The decoiler and straightener ensure the material is fed properly. The forming rollers are the heart of the machine, each stand contributing to the final shape. The cutoff press uses hydraulic or mechanical force to cut the jambs. Maybe mention PLC controls for automation, adjusting speed, and monitoring the process.