- Floor Decking Roll Forming Machine

Floor decking roll forming machines are essential equipment for producing high-quality metal floor decking sheets used in construction projects. These machines are designed to efficiently and accurately transform raw materials, typically steel coils, into customized floor decking profiles with precision and consistency. They play a crucial role in the manufacturing process by ensuring the production of durable and structurally sound floor decking panels.

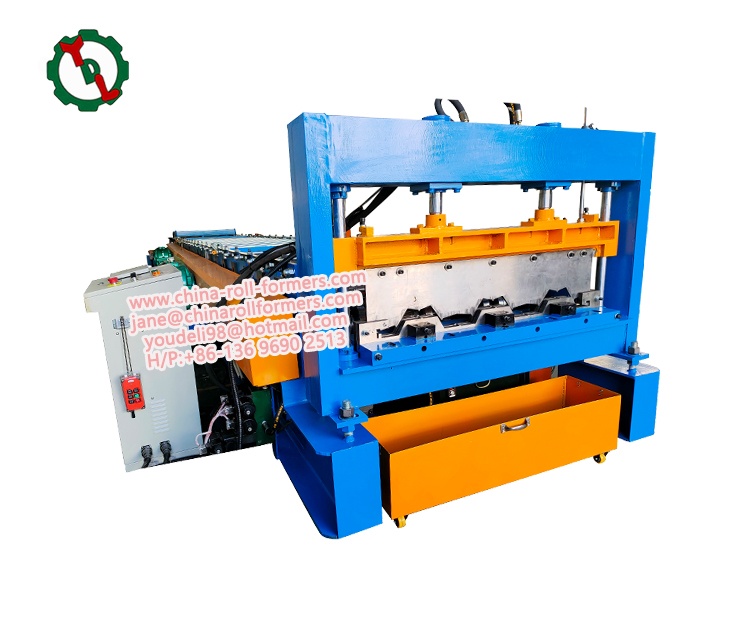

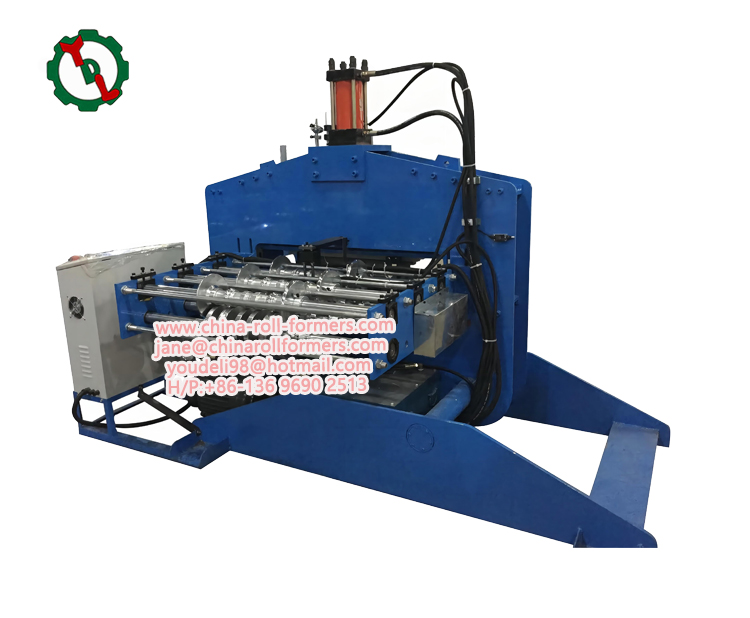

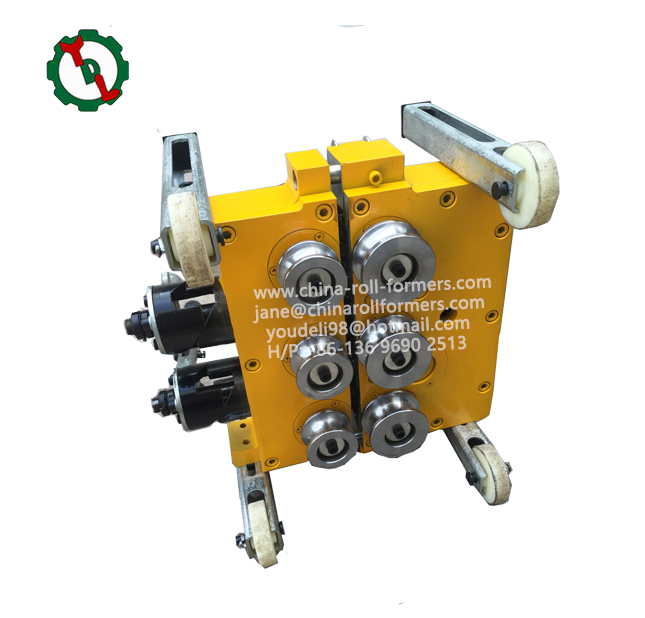

The floor decking roll forming machine operates by passing the metal coil through a series of rollers and dies that gradually shape and cut the material into the desired profile. The machine is equipped with various components such as decoilers, leveling units, roll forming stations, cutting mechanisms, and control systems that work together seamlessly to produce consistent and accurate results.

One of the key advantages of using a floor decking roll forming machine is the ability to customize the design and dimensions of the floor decking panels to meet specific project requirements. This flexibility allows construction companies to produce floor decking sheets of varying lengths, widths, thicknesses, and shapes, ensuring a perfect fit for each application.

In addition to customization options, floor decking roll forming machines are known for their high production efficiency and cost-effectiveness. These machines are capable of producing large quantities of floor decking panels in a short amount of time, reducing labor costs and increasing productivity. They also require minimal maintenance and can operate continuously for extended periods, making them a reliable and dependable solution for manufacturers.

Furthermore, floor decking roll forming machines are designed to deliver exceptional accuracy and precision in the production process. The precise control systems and advanced technology incorporated into these machines ensure that each floor decking panel is manufactured with consistent dimensions and quality, meeting the highest industry standards for performance and durability.