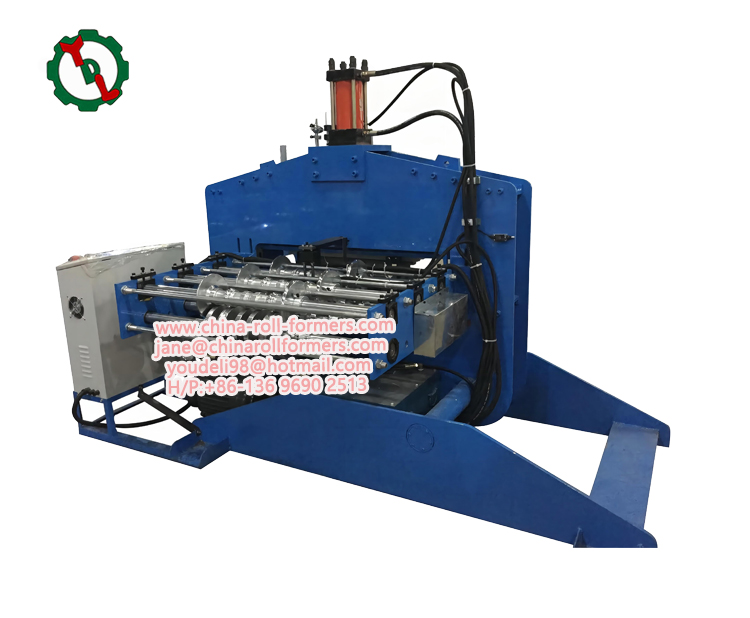

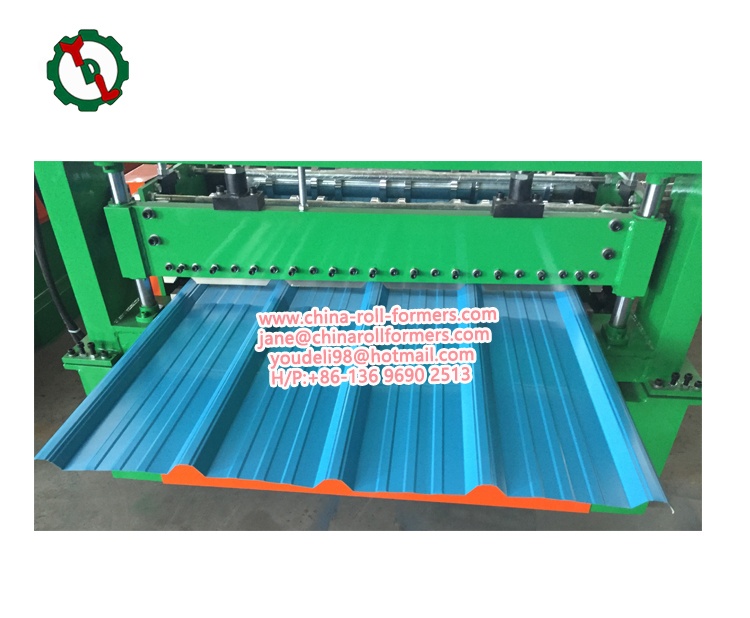

- Corrugated Roofing Machine, Roofing Sheet Roll Forming Machine

Ribbed roof sheet edge forming machine is mainly composed of edge forming system, cutting system, control system and so on. The working principle is to press raw materials (such as colored steel plates, galvanized steel plates, etc.) into roof panels with specific rib shapes through the rolling molding system, and then cut the fixed length through the cutting system, and finally realize the automatic control of the entire production process by the control system.