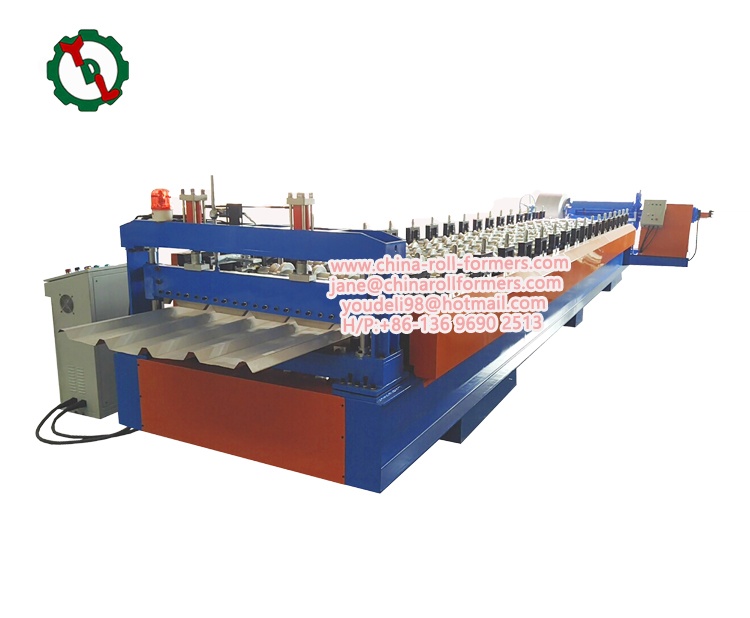

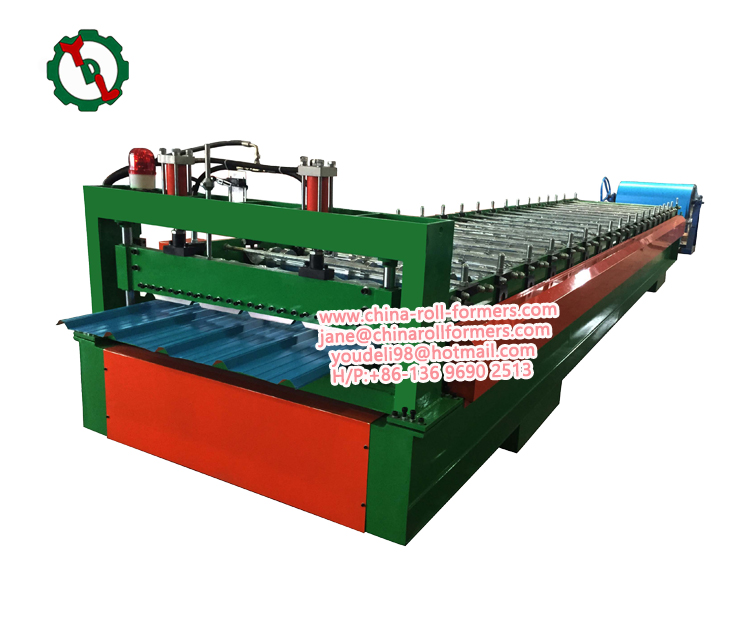

- Trapezoidal Roofing Machine

With its high-quality output and user-friendly features, the Trapezoid Roof Machine is attracting interest in the construction industry. The production of roofing sheets with trapezoidal ribs is being revolutionized by this equipment, giving roofing manufacturers a more effective and affordable option. The roll forming procedure produces roofing sheets that are uniformly sized, properly formed, and of a constant quality. The Trapezoid Roof Machine is outfitted with cutting-edge technology that improves its accuracy and dependability, such as PLC control systems and automatic cutting systems. Any roofing manufacturer aiming to maximize their revenues and optimize their production process should use this equipment.