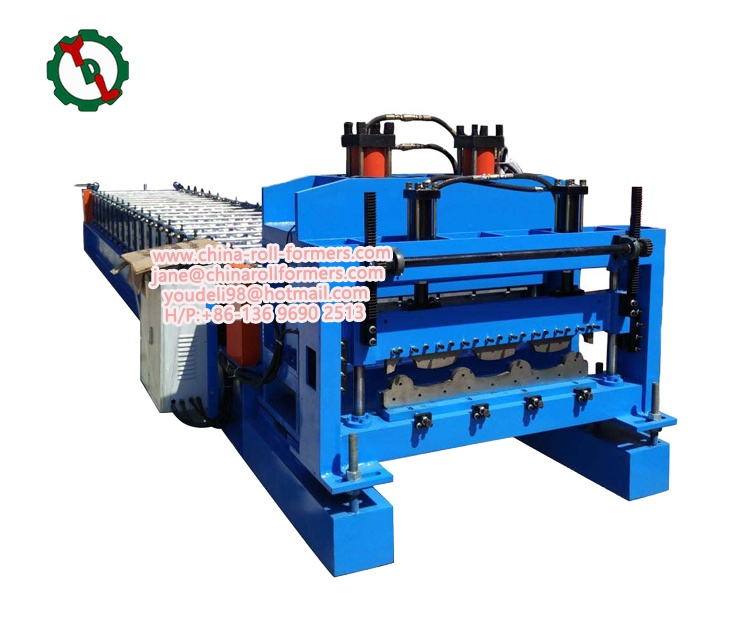

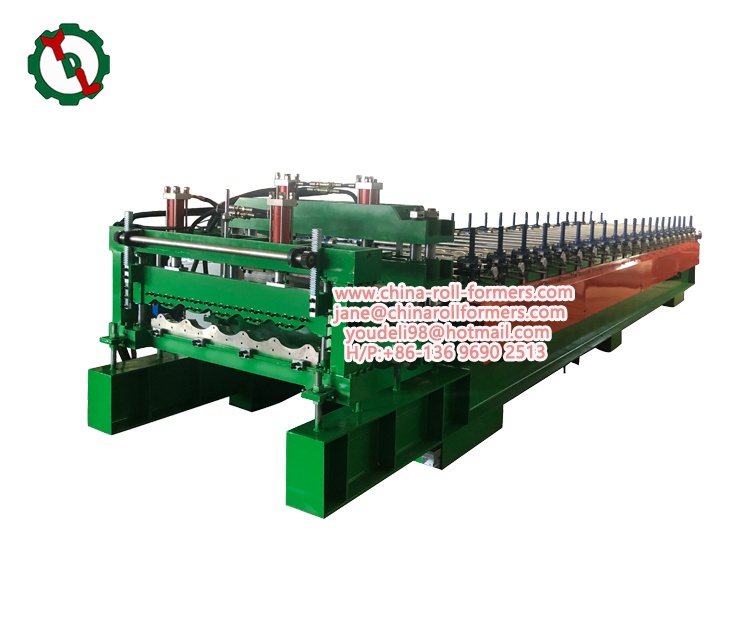

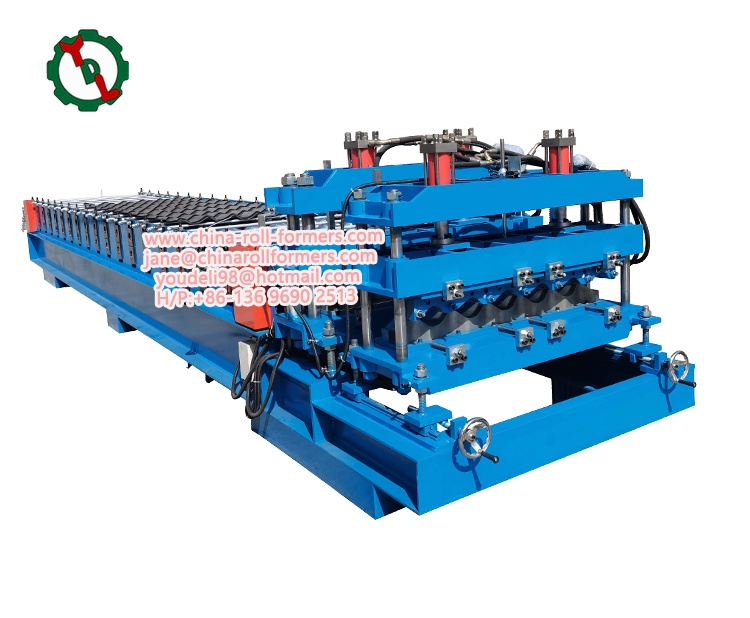

- Tile Roofing Machine

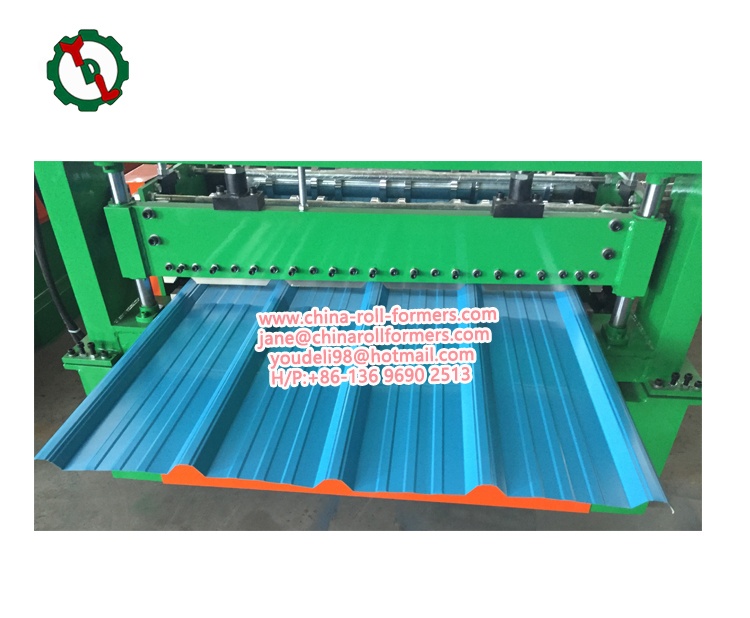

Due to its toughness and attractive appearance, tile roofing is a preferred option among homeowners. However, if you don't have access to a dependable tile roofing equipment, installing tile roofing can be difficult.

A gadget called a tile roofing machine is made to make the process of molding and shaping tile roofing sheets easier. This equipment can create premium tiles that can survive inclement weather. It is a crucial tool for skilled roofers who want to build long-lasting, high-quality roofing.

Manual labor, which can be physically and mentally taxing, is avoided by using a tile roofing machine. You will have enough roofing tiles to completely cover your roof in a short amount of time thanks to the machine's quick manufacturing capability.