- Storage Rack Roll Forming Machine

When it comes to efficiently storing and organizing products in warehouses, storage racks play a crucial role. And the key to producing strong and durable storage racks lies in the quality of the roll forming machines used in the manufacturing process.

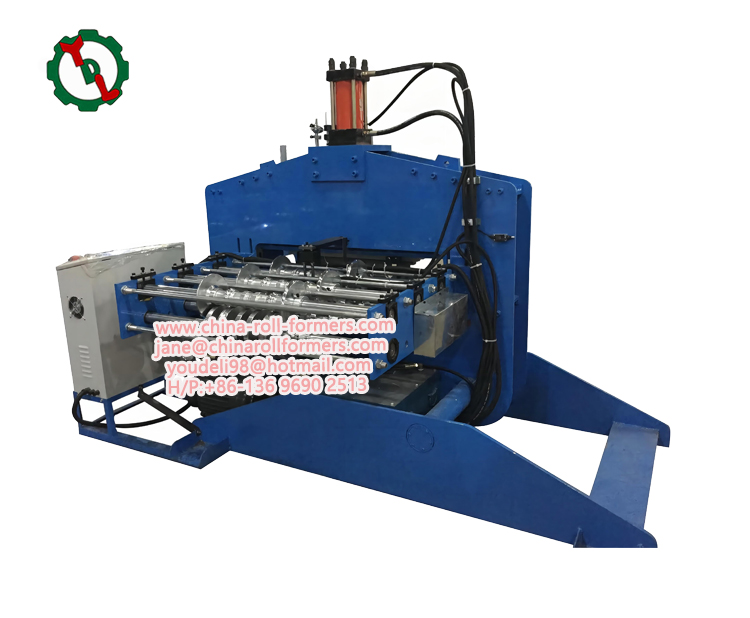

One popular type of roll forming machine used for producing storage racks is the P Girder Roll Forming Machine with Fly Cutting. This advanced machine is designed to efficiently and accurately produce P girder profiles that are commonly used in the construction of storage racks.

The P Girder Roll Forming Machine with Fly Cutting is equipped with cutting-edge technology that enables it to form P girder profiles with precision and speed. The fly cutting feature allows for continuous cutting of the profiles, ensuring a smooth and efficient production process.

The machine is also capable of forming P girder profiles with different dimensions and thicknesses, making it versatile and suitable for various storage rack applications. Whether you need to produce heavy-duty racks for storing large and heavy items or lighter racks for smaller products, this machine can handle it all.

In addition to its exceptional forming capabilities, the P Girder Roll Forming Machine with Fly Cutting is also designed for ease of operation and maintenance. Its user-friendly interface and intuitive controls make it easy for operators to set up and run the machine, while its sturdy construction ensures long-term durability and reliability.

By investing in a high-quality P Girder Roll Forming Machine with Fly Cutting, manufacturers can produce storage racks that are not only structurally sound and durable but also cost-effective and efficient. With the ability to produce racks of various sizes and configurations, this machine offers the versatility and performance needed to meet the demands of modern warehouse storage solutions.

In conclusion, the P Girder Roll Forming Machine with Fly Cutting is an indispensable tool for manufacturers looking to produce strong and reliable storage racks. Its advanced technology, precision forming capabilities, and ease of operation make it a valuable asset for any warehouse or storage rack production facility.