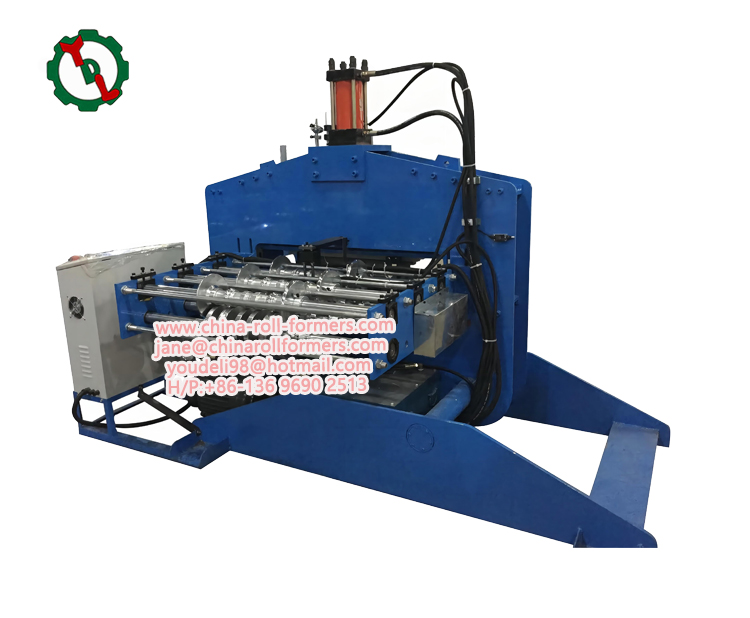

- Standing Seam Curving Machine

The Automatic Adjusted Smooth Curving Machine is a specialized industrial system designed to create precise, continuous curves in materials like metal, plastic, composites, or wood. Here's a structured overview of its key features, applications, and technology:

1、Core Functionality Automation: Operates with minimal human intervention, using programmed instructions or AI-driven algorithms to adjust parameters in real-time.

2、Adjustability: Dynamic Calibration: Sensors and feedback systems automatically modify force, speed, or temperature to maintain curve quality.

Material Adaptation: Adjusts for material thickness, elasticity, or hardness (e.g., aluminum vs. carbon fiber).

3、Smooth Curving: Seamless Results: Eliminates joints or imperfections via processes like hydroforming, stretch forming, or robotic grinding.

Precision Control: Uses CNC (Computer Numerical Control) or robotic arms for micro-adjustments, ensuring consistent curvature.