Slitting Machine: A Must-Have Equipment for Precision Cutting

Slitting machine is a versatile piece of equipment used in various manufacturing industries. It is designed to cut large rolls of materials, such as paper, plastic, metal, and fabric, into smaller, more manageable sizes. The machine is commonly used in the packaging, printing, paper, and textile industries to produce rolls of different widths and lengths. In this article, we will discuss the features, benefits, and applications of a slitting machine.

Features of a Slitting Machine

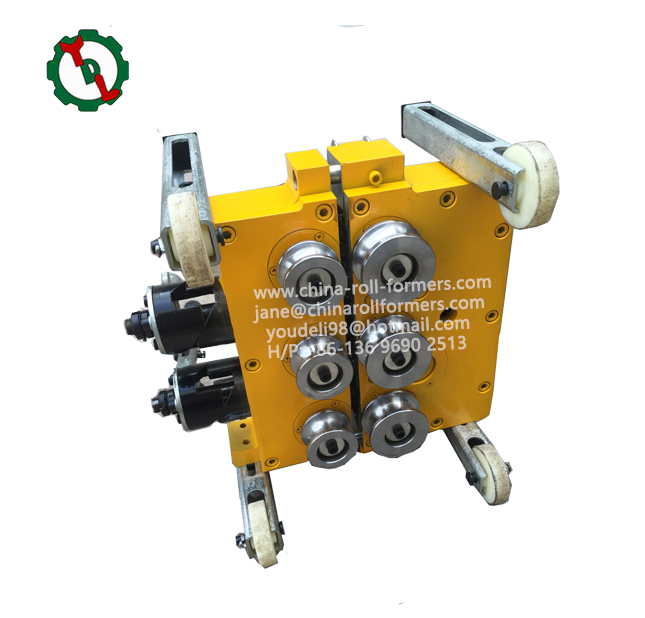

A slitting machine is a precision cutting tool that is designed to handle a wide range of materials. It consists of several components, including a unwinder, slitting head, rewinder, and control panel. The slitting head contains razor blades or circular knives that are used to cut the material into the desired width. The unwinder feeds the material into the slitting head, and the rewinder collects the slitted strips into smaller rolls.

The machine’s cutting accuracy and speed depend on the type of material, blade type, and machine specifications. Modern slitting machines are equipped with advanced features, such as automation, computer control, and adjustable tension, to enhance their performance.

Benefits of a Slitting Machine

A slitting machine provides many benefits to manufacturers, including:

1. Efficient Production: With a slitting machine, manufacturers can produce large volumes of rolls quickly, accurately, and with minimal waste.

2. Versatile: The machine can handle a wide range of materials, including paper, plastic film, fabric, metal foils, and adhesive tapes.

3. Cost-Effective: The machine’s high precision cutting minimizes waste, reduces labor costs, and improves production efficiency, leading to significant cost savings.

4. Customizable: The machine’s settings can be customized to produce different widths, thicknesses, and lengths of material.

Applications of a Slitting Machine

Slitting machines have a broad range of applications, including:

1. Packaging: Slitting machines are used to produce rolls of different widths and lengths to create packaging materials, such as plastic films and cardboard.

2. Printing: The machine is used to produce paper rolls of different sizes for printing applications, such as newspapers, magazines, and books.

3. Textile: The machine can cut and rewind fabric rolls for various textile products, such as clothing, upholstery, and curtains.

4. Automotive: The machine is used to produce rolls of materials for automotive applications, such as insulation and soundproofing materials.

In conclusion, a slitting machine is an essential piece of equipment for precision cutting. It provides numerous benefits to manufacturers, including efficiency, versatility, cost-effectiveness, and customization. With its broad range of applications, the machine is a valuable investment for any manufacturing industry that requires precision cutting of large rolls of materials.