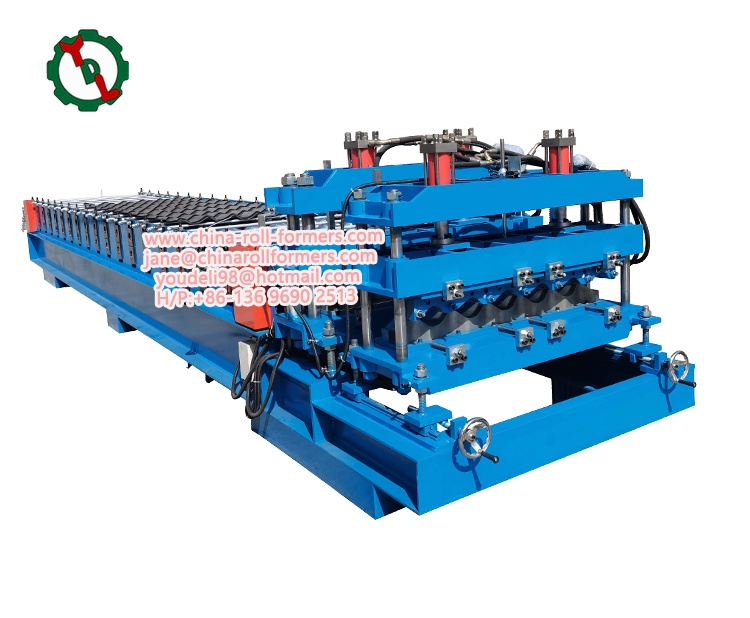

- Eave Gutter Machine

A ground-breaking piece of manufacturing machinery called the Eave Gutter Machine is intended to make seamless eaves gutters with astounding efficiency and accuracy. Because of this cutting-edge technology, it is now possible to manufacture seamless gutters that exactly fit against the roofline, revolutionizing the eaves gutter industry.

The eaves gutter manufacturing industry has altered as a result of Eave Gutter Machine's innovative technology. Aluminum, copper, and steel are just a few of the materials that can be used to make gutters. Because of its adaptability, it may be used by all sizes of roofing manufacturers and builders.

Eave Gutter Machine manufactures superior-quality eaves gutters that are free of leaks, blockages, and other flaws using specialized software and advanced manufacturing techniques. The gutters are likewise precisely cut.lengths, ensuring they fit perfectly into the eaves spaces of any roof.