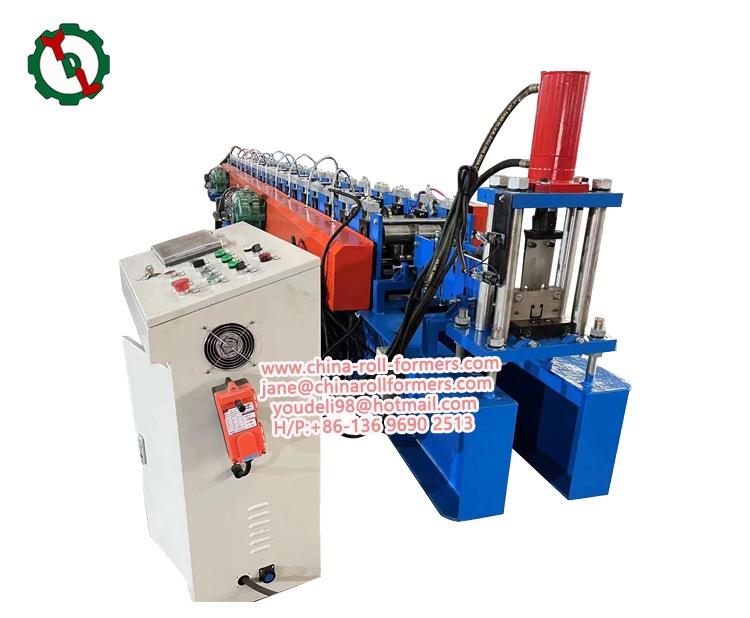

- Double Layer Roof Machine

Producing two different types of roofing sheets simultaneously is one of the double-layer roof machine's key benefits, which helps to boost output. Compared to conventional machines, the machine can create twice as many roofing sheets thanks to cutting-edge technology. Other roofing sheet profiles, such as IBR, Corrugated, and others, can also be produced using the machine.

This machine also has the advantage of producing roofing sheets from a range of materials, such as zinc, aluminum, and galvanized steel. When it comes to selecting roofing sheets with various levels of durability and visual appeal, this aspect is essential for making sure that customers have a wide variety of options.