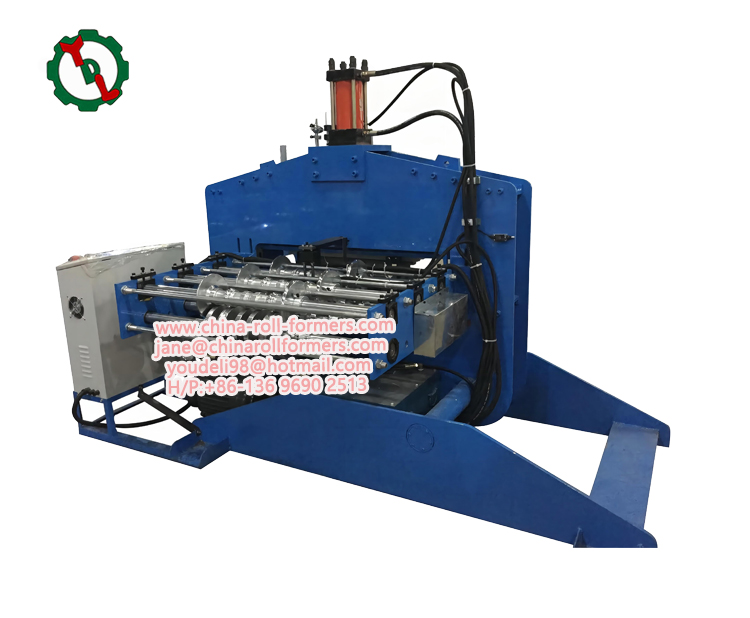

This innovative machine combines the power of hydraulic pressure with cutting-edge technology to quickly and accurately crimp and curve metal materials. Whether you are working on roofing, siding, gutters, or any other metal fabrication project, this machine is a game-changer.

The Automatic Hydraulic Crimping Curving Machine is designed to streamline the metal forming process, saving you time and labor costs. With its automatic operation, you can easily adjust the crimping and curving settings to meet your specific project requirements. This machine is perfect for both high-volume production runs and custom fabrication projects.

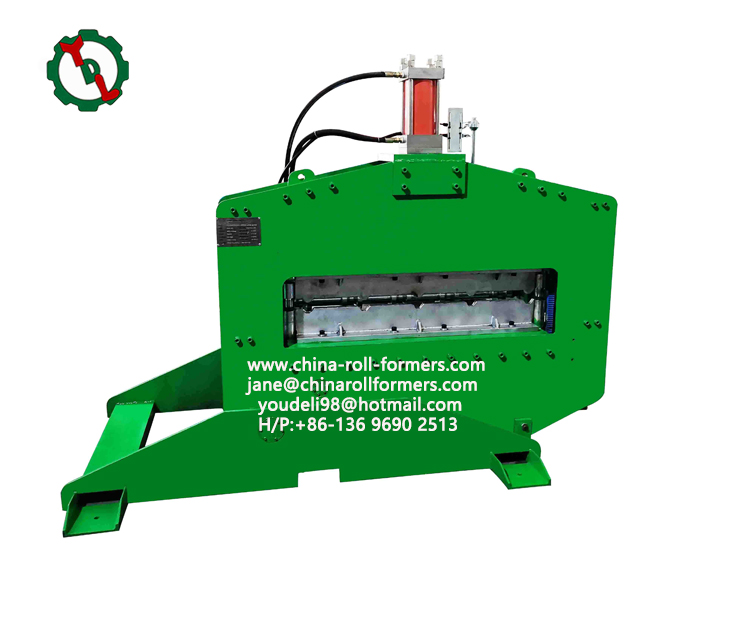

One of the key benefits of this machine is its precision and consistency. By using hydraulic pressure to crimp and curve the metal materials, you can achieve a perfect finish every time. This ensures that your products are of the highest quality, meeting or exceeding industry standards.

Another advantage of the Automatic Hydraulic Crimping Curving Machine is its versatility. It can work with a wide range of metal materials, including steel, aluminum, copper, and more. This means that you can use it for a variety of applications, from roofing and siding to architectural accents and decorative elements.

In addition to its efficiency and accuracy, this machine is also easy to use and maintain. With its user-friendly interface and durable construction, it will quickly become an essential tool in your workshop or manufacturing facility. Plus, with regular maintenance and servicing, you can keep it running smoothly for years to come.