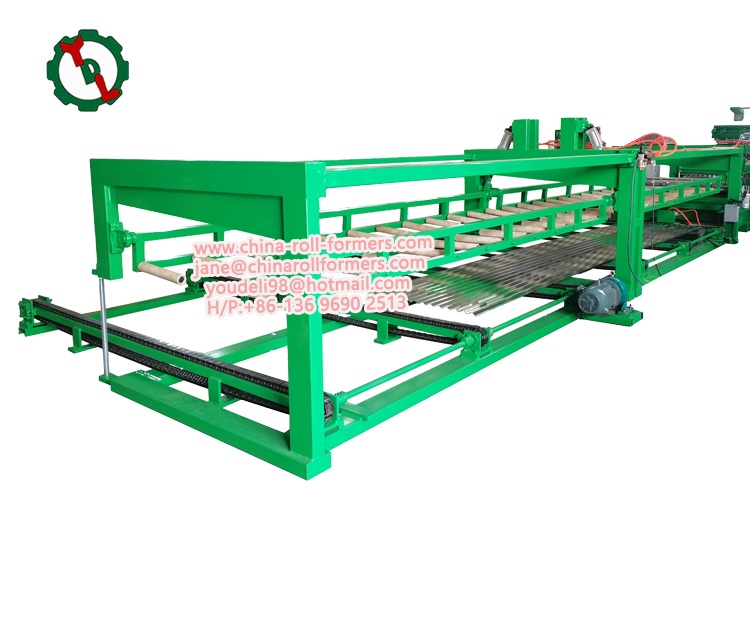

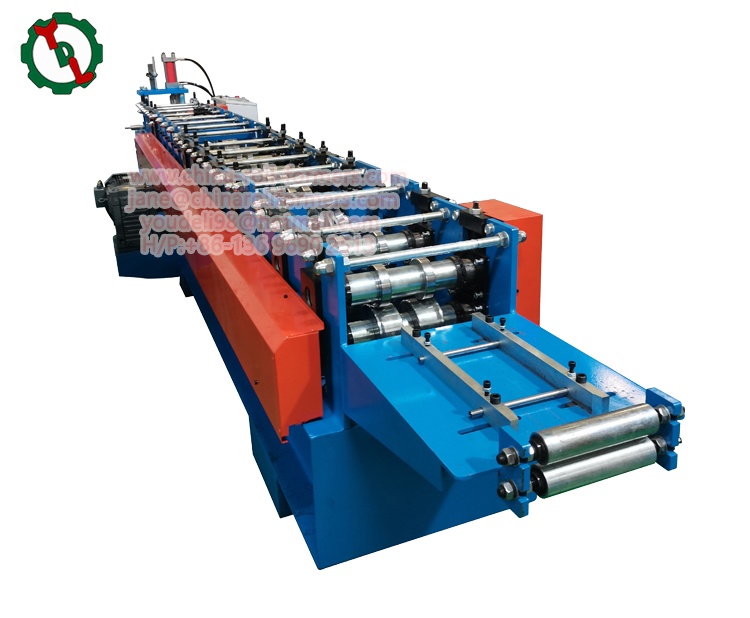

- Automatic Stacker

The functionality of these machines has been revolutionized by the introduction of a new Automatic Stacker for Double Furring Machines. The stacker, which can easily handle even the largest loads and is designed to streamline processes and boost efficiency, is the ideal complement to any production plant.

A sophisticated computer system that may be programmed to do a wide range of functions is included with the stacker. It is a great option for businesses trying to increase production and cut costs because it is simple to use and requires little training.

Numerous safety elements on the Automatic Stacker are also provided to guarantee worker safety while using the equipment. These comprise sensors that are capable of seeing any unexpected activity and instantly shutting down the system to avoid accidents.