PU (Polyurethane) sandwich panels are widely used in the construction industry for their excellent thermal insulation properties and lightweight yet strong structure. These panels consist of two outer metal sheets (typically steel or aluminum) and a core material made of PU foam. The manufacturing process of PU sandwich panels involves the use of specialized equipment known as a PU sandwich panel machine. In this article, we will explore how a PU sandwich panel machine works and discuss the key features to consider when buying one.

I. Working Principle of a PU Sandwich Panel Machine

A PU sandwich panel machine is designed to automate the production process of PU sandwich panels. The machine consists of several components that work together to produce high-quality panels efficiently. Here is an overview of the working principle of a typical PU sandwich panel machine:

- Material Feeding: The process begins with the feeding of the core material (PU foam) and the outer metal sheets into the machine. The metal sheets are typically unwound from coils, while the PU foam is supplied in the form of liquid chemicals that react to form the foam.

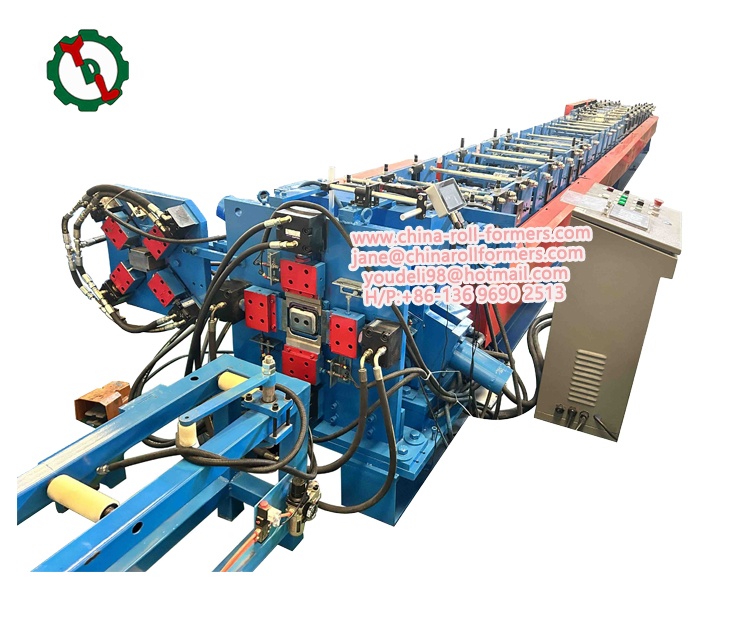

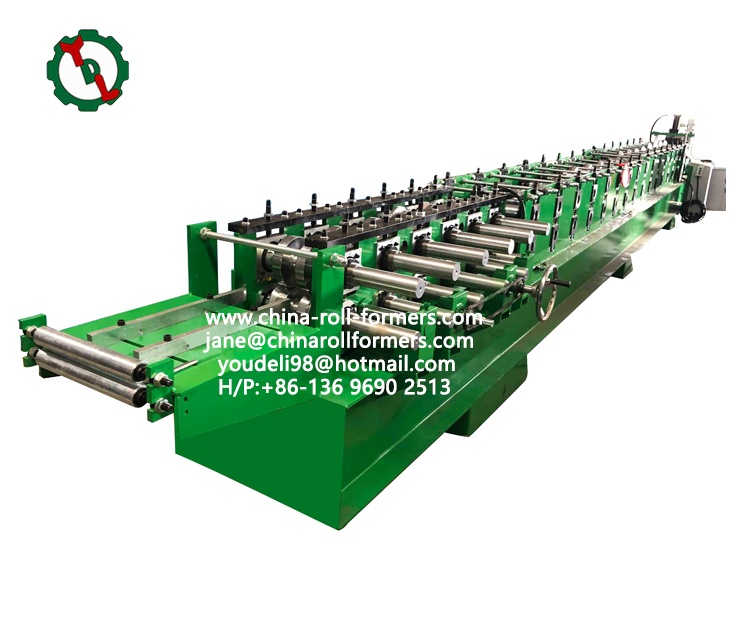

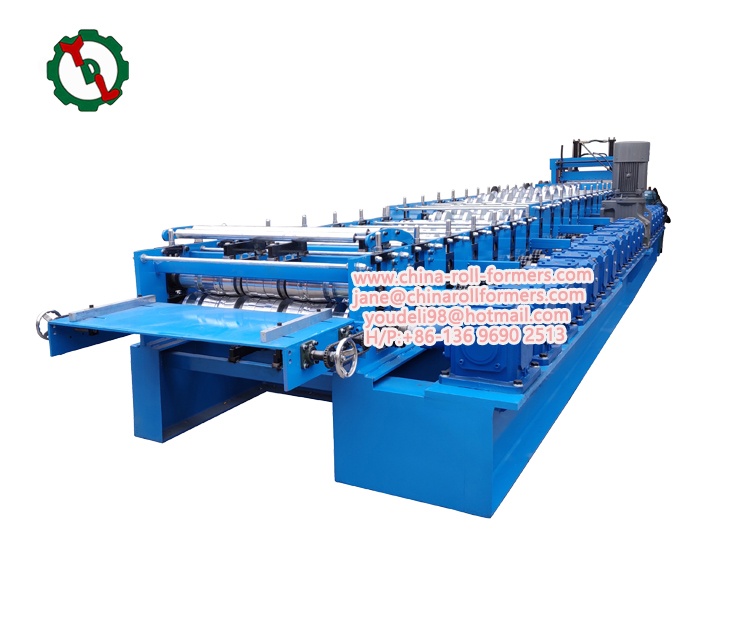

- Roll Forming: The metal sheets pass through a series of rollers that shape them into the desired profile. This process is known as roll forming and is crucial for ensuring the panels have the correct dimensions and geometry.

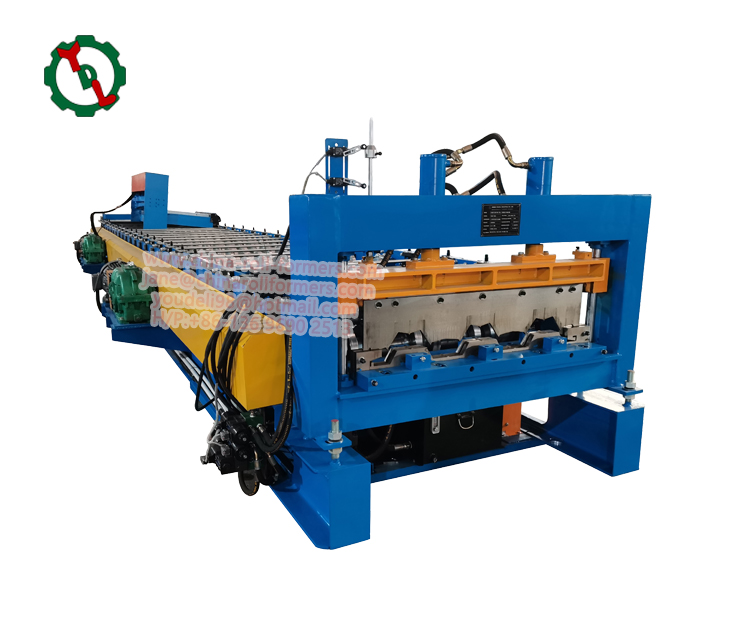

- Panel Assembly: Once the metal sheets are formed, they are combined with the PU foam core to form a sandwich panel. The core material is injected between the two metal sheets, and the panel is assembled under pressure to ensure a strong bond between the layers.

- Curing: After assembly, the panels are moved to a curing oven where they are subjected to heat and pressure. This process helps the PU foam to cure and bond with the metal sheets, resulting in a rigid and stable panel structure.

- Cutting and Stacking: Once the panels have cured, they are cut to the desired length and stacked for further processing or packaging.

II. Key Features to Consider When Buying a PU Sandwich Panel Machine

When investing in a PU sandwich panel machine, it is important to consider several key features to ensure that you choose the right machine for your specific needs. Here are some essential features to look for:

- Production Capacity: The production capacity of the machine determines how many panels it can produce in a given timeframe. Choose a machine that can meet your production requirements without compromising on quality.

- Panel Dimensions: Consider the maximum and minimum panel dimensions that the machine can produce. Ensure that the machine can accommodate the panel sizes you need for your projects.

- Material Compatibility: Check the compatibility of the machine with different types and thicknesses of metal sheets and PU foam. A versatile machine that can work with a variety of materials will offer more flexibility in your production process.

- Automation Level: The level of automation of the machine can significantly impact its efficiency and ease of operation. Look for a machine that offers a high degree of automation, including features such as automatic material feeding, panel assembly, and cutting.

- Energy Efficiency: Consider the energy efficiency of the machine, as this can impact your operating costs. Look for features such as energy-efficient heating systems and optimized production processes.

- Ease of Maintenance: Choose a machine that is easy to maintain and service. Look for features such as easy access to components, user-friendly controls, and reliable performance.

- Safety Features: Ensure that the machine is equipped with adequate safety features to protect operators and prevent accidents. Look for features such as emergency stop buttons, safety guards, and interlock systems.

- Supplier Reputation: Finally, consider the reputation of the machine supplier. Choose a supplier with a proven track record of providing high-quality machines and excellent customer support.

- Material Handling System: The material handling system of a PU sandwich panel machine is critical for ensuring smooth and efficient production. Look for a machine with a reliable material feeding and handling system that can accommodate different types and thicknesses of metal sheets and PU foam. A well-designed material handling system will minimize downtime and maximize productivity.

- Panel Thickness Control: Consistent panel thickness is essential for ensuring the structural integrity and thermal insulation properties of PU sandwich panels. Choose a machine with precise panel thickness control mechanisms, such as adjustable rollers or pressure sensors, to ensure uniform panel thickness throughout the production process.

- Quality Control Features: Quality control is paramount in the manufacturing of PU sandwich panels to ensure that the final products meet industry standards and customer requirements. Look for a machine equipped with quality control features such as real-time monitoring systems, defect detection sensors, and automated rejection mechanisms to identify and address any issues during production.

- Customization Options: Depending on your specific production needs, you may require customization options such as the ability to produce panels with custom profiles, sizes, or surface finishes. Choose a machine that offers customization options to meet the unique requirements of your projects and clients.

- User-Friendly Interface: An intuitive and user-friendly interface is essential for optimizing machine operation and minimizing operator errors. Look for a machine with a modern and easy-to-use control panel that allows operators to monitor and adjust production parameters efficiently.

- After-Sales Support: Investing in a PU sandwich panel machine is a significant decision, and you’ll want to ensure that you have access to reliable after-sales support and technical assistance. Choose a machine supplier that offers comprehensive after-sales services, including installation, training, maintenance, and spare parts availability.

- Cost and Return on Investment: While the initial cost of purchasing a PU sandwich panel machine is an important consideration, it’s essential to evaluate the long-term return on investment (ROI). Consider factors such as production efficiency, material savings, labor costs, and potential revenue generation when assessing the overall cost-effectiveness of the machine.

III. Conclusion

A PU sandwich panel machine is a complex piece of equipment that plays a crucial role in the production of PU sandwich panels. When buying a PU sandwich panel machine, it’s essential to consider a range of key features to ensure that you invest in a machine that meets your production requirements and delivers high-quality panels consistently. By evaluating factors such as production capacity, panel dimensions, material compatibility, automation level, energy efficiency, ease of maintenance, safety features, supplier reputation, customization options, user interface, after-sales support, and cost-effectiveness, you can make an informed decision and maximize the success of your PU sandwich panel manufacturing operation.