In the construction and manufacturing industries, purlins play a crucial role in supporting roofing systems and structural frameworks. Among the various types of purlins, the C purlin is one of the most commonly used, particularly in commercial, industrial, and residential buildings. To produce C purlins efficiently and accurately, manufacturers rely on specialized equipment known as the Machine à panneresses C. In this article, we will explore what a C purlin machine is, how it works, and the benefits it offers in modern construction.

Qu'est-ce qu'une machine à fabriquer des pannes en C ?

A C purlin machine is a piece of automated equipment used to manufacture C-shaped steel purlins. Purlins are horizontal structural elements used to support the roof or walls of buildings, acting as beams that help distribute loads. The “C” shape refers to the cross-sectional profile of the purlins, which resemble the letter “C” and offer a balance of strength, flexibility, and cost-efficiency.

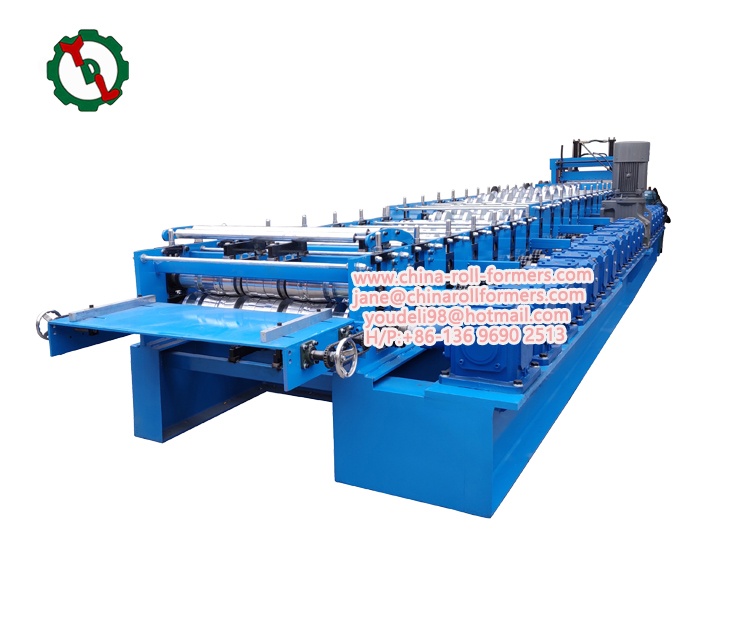

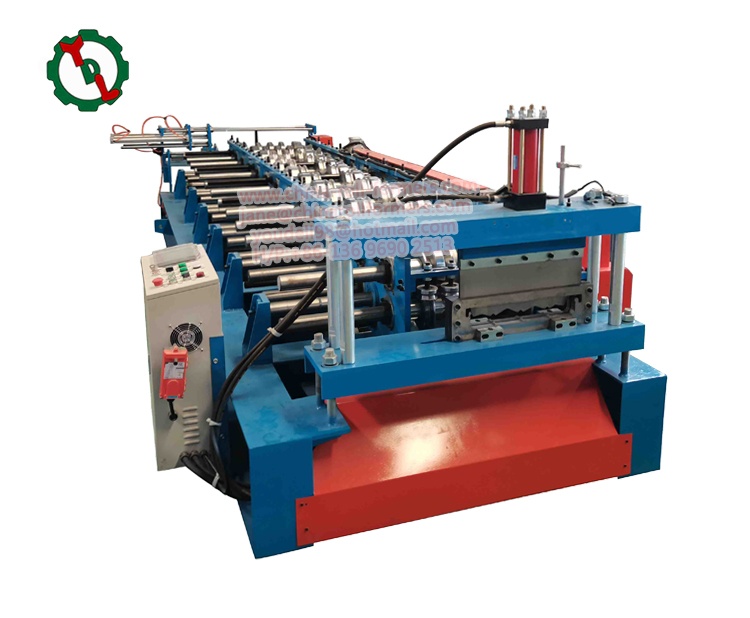

It is designed to convert raw steel coil or strip into precisely shaped C purlins by continuously forming, cutting, and punching the material. These machines are typically used in large-scale production environments, where speed and consistency are crucial for meeting high demand and maintaining structural quality.

How Does a C Purlin Machine Work?

The process of manufacturing C purlins with a C purlin machine involves several stages, all of which are carried out automatically. Here’s a breakdown of how the machine works:

- Feeding Raw Material

The process begins by feeding a coil of steel into the machine. This coil is typically made of high-quality galvanized or pre-painted steel to ensure durability and resistance to corrosion. The machine is equipped with a feeding system that unwinds and straightens the steel coil, preparing it for the next step in the forming process. - Formage de rouleaux

The straightened steel is then passed through a series of rollers, which gradually bend the material into the desired “C” shape. Roll forming is a continuous process where the steel passes through multiple sets of rollers that shape it without cutting, ensuring a smooth and precise profile. - Punching and Cutting

As the steel moves through the machine, it can be punched or drilled at specific intervals to create holes for bolts or fasteners. These holes are necessary for attaching the purlins to the roof or other structural elements. After punching, the machine uses a cutting tool to slice the purlin to the required length. - Output and Finishing

Once the purlins are formed, punched, and cut, they are ejected from the machine and ready for use in construction. Depending on the machine’s design, additional features like bending or trimming can be added to the finished purlins for further customization.

C purlin machines are highly automated, with advanced control systems that allow manufacturers to easily adjust the size, shape, and features of the purlins. This automation ensures that purlins are produced quickly and consistently, with minimal human intervention.

Key Features of a C Purlin Machine

- Ajustement

One of the key features of a C purlin machine is its adjustability. Most machines allow users to change the dimensions of the purlins, including width, height, and thickness, depending on the project requirements. This versatility makes the machine suitable for a wide range of applications in construction, from residential homes to large commercial buildings. - High-Speed Production

They are designed for high-speed production, capable of creating large quantities of purlins in a short amount of time. This high throughput is essential for manufacturers looking to meet the demands of the construction industry, where speed and efficiency are critical. - Precision and Consistency

The machine’s ability to produce purlins with precise dimensions and consistent quality is one of its most significant advantages. The automated processes, combined with advanced control systems, ensure that each purlin is manufactured to meet exact specifications, which is crucial for maintaining the integrity and safety of the final structure. - Durability and Reliability

They are typically built to last, with high-quality components designed for continuous operation in demanding industrial environments. They are engineered to withstand the wear and tear of high-volume production, making them reliable assets for manufacturers. - Customizable Add-Ons

They come with the option for additional features such as integrated punching, shearing, and bending. These features allow manufacturers to further customize their purlins for specific construction needs, such as adding holes for mounting or adjusting the profile for different structural applications.

Advantages of Using a C Purlin Machine

- Rapport coût-efficacité

The automated nature of C purlin machines significantly reduces labor costs. With minimal human intervention, manufacturers can produce large volumes of high-quality purlins at a lower cost per unit. This cost-efficiency is a significant factor in the widespread adoption of machines in the construction industry. - Increased Production Efficiency

With the ability to quickly form, punch, and cut purlins, they help streamline the production process. The high-speed operation means that manufacturers can keep up with the increasing demand for steel purlins in construction projects, reducing lead times and improving delivery schedules. - Enhanced Structural Integrity

The precision offered by C purlin machines ensures that each purlin is manufactured to exact specifications, contributing to the overall structural integrity of the building. Well-made purlins are critical for ensuring that roofing systems can withstand various loads, including wind, snow, and other environmental stresses. - Options de personnalisation

They offer a high degree of customization, allowing manufacturers to produce purlins in a range of sizes and profiles. Whether a project requires standard C purlins or custom sizes for specific structural needs, the machine can accommodate a wide variety of designs, making it adaptable to different building types and applications. - Improved Material Utilization

Since the purlin machine uses continuous steel coils, manufacturers can optimize material usage by minimizing scrap. The precise cutting and forming processes ensure that the material is used efficiently, reducing waste and lowering material costs. - Peu d'entretien

Modern C purlin machines are designed to require minimal maintenance, thanks to their robust construction and high-quality components. This means less downtime for repairs and more consistent production, which is critical for manufacturers seeking to maintain a high level of productivity.

Applications of C Purlins

C purlins are used in a wide variety of construction applications, especially in the framing and support systems of buildings. Some common uses include:

- Roofing Structures: C purlins are commonly used as the supporting framework for roofs in both residential and commercial buildings. They provide structural support for roofing panels, ensuring the stability and safety of the roof.

- Wall Frames: In addition to roofing, C purlins are also used in the construction of wall frames, where they serve as load-bearing elements that support cladding materials.

- Bâtiments agricoles: In agricultural settings, C purlins are often used for constructing barns, sheds, and other structures that require a durable and cost-effective support system.

- Industrial and Commercial Buildings: C purlins are commonly found in large-scale industrial and commercial buildings, where they provide the necessary strength and flexibility to support large roofing systems and wall panels.

Conclusion

C purlin machines play a vital role in the production of C-shaped steel purlins, which are essential components in the construction of roofing and structural systems. These machines offer numerous advantages, including high-speed production, precision, cost-effectiveness, and flexibility. With the ability to produce purlins in a variety of sizes and profiles, they help meet the diverse demands of the construction industry, contributing to the development of safer, more efficient, and cost-effective buildings.

As construction projects continue to increase in complexity and scale, the demand for reliable, high-quality purlins will only grow. C purlin machines are well-positioned to meet this demand, ensuring that the building industry remains efficient, sustainable, and capable of supporting the world’s growing infrastructure needs.