Introduction

In modern construction and manufacturing, efficiency and precision are essential for producing high-quality building materials. A machine de formage de panneaux muraux par laminage is a crucial piece of equipment designed to manufacture metal wall panels used in residential, commercial, and industrial structures. This machine ensures uniformity, strength, and durability, making it a preferred choice for builders and manufacturers.

This guide provides a comprehensive overview of the wall panel roll forming machine, covering its working principles, key components, benefits, and applications.

What Is a Wall Panel Roll Forming Machine?

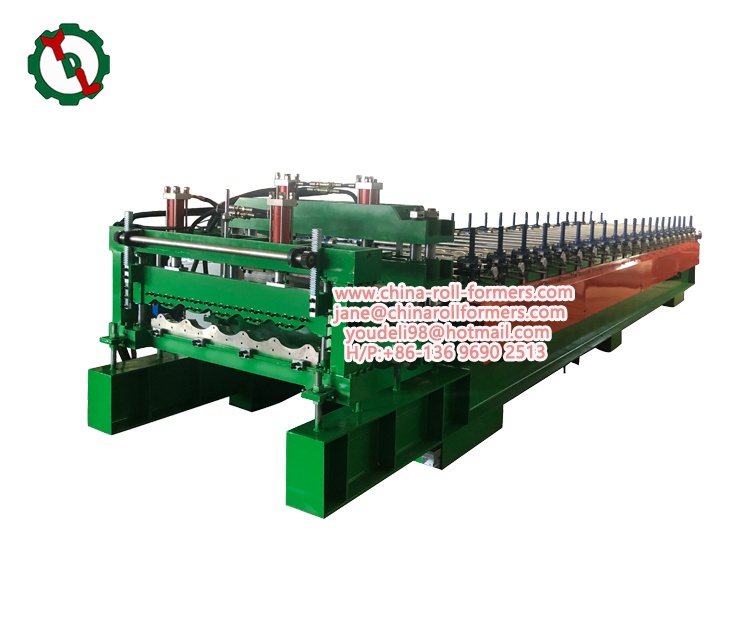

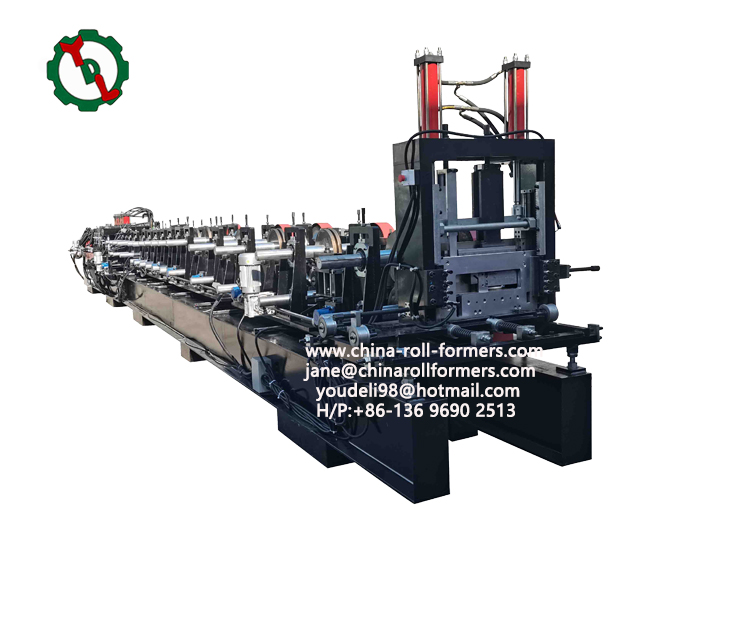

It is an advanced manufacturing system that continuously forms metal sheets into wall panels through a series of rollers. These machines are widely used in the construction industry to create high-precision wall panels made from steel, aluminum, or other metals.

Unlike traditional fabrication methods, roll forming is highly efficient, producing consistent results with minimal material waste. The automation in these machines allows for mass production with superior accuracy and quality.

How Does a Wall Panel Roll Forming Machine Work?

The operation of a wall panel roll forming machine involves several stages:

- Decoiling – The raw metal coil is loaded onto a decoiler, which feeds the material into the machine.

- Leveling and Feeding – The sheet is flattened and guided into the forming section.

- Processus de laminage – The sheet passes through a series of rollers that gradually shape it into the desired profile.

- Coupe à la longueur – Once the panel reaches the required length, an automatic cutting system trims it precisely.

- Stacking and Collecting – The finished panels are neatly stacked for transportation or further processing.

The entire process is automated, minimizing human intervention and ensuring high production efficiency.

Key Components of a Wall Panel Roll Forming Machine

A wall panel roll forming machine consists of several essential components that work together to produce high-quality wall panels. These include:

- Decoiler : Holds and feeds the metal coil into the machine.

- Stations de formage de rouleaux : A series of rollers that gradually bend the metal into the desired profile.

- Hydraulic Cutting System: Cuts the panels to the required length after forming.

- Système de contrôle : Usually equipped with a PLC (Programmable Logic Controller) for automated operation.

- Stacking System: Collects and arranges the finished panels for easy handling.

These components ensure precision, speed, and durability in the roll forming process.

Avantages de l'utilisation d'une profileuse pour panneaux muraux

Using it offers numerous advantages in the construction and manufacturing industries:

1. High Production Efficiency

The automation of roll forming machines allows for continuous production, reducing downtime and increasing output. This is especially beneficial for large-scale projects that require a high volume of wall panels.

2. Consistent Quality and Precision

Manual fabrication methods often result in variations, but a wall panel roll forming machine ensures uniformity in dimensions and quality. The use of computer-controlled systems guarantees precise measurements and perfect panel shapes.

3. Cost-Effective Manufacturing

Since the roll forming process minimizes material waste, it significantly reduces production costs. Additionally, the high-speed operation of the machine lowers labor costs, making it a cost-effective solution.

4. Polyvalence dans la conception des panneaux

These machines can produce a variety of panel designs, including corrugated, ribbed, and flat panels. Customization options allow manufacturers to create different profiles based on project requirements.

5. Durability and Strength

Wall panels produced by a wall panel roll forming machine are strong, lightweight, and resistant to environmental factors such as corrosion and extreme weather conditions. This makes them ideal for long-term construction projects.

6. Environmentally Friendly

The roll forming process generates minimal waste, reducing the environmental impact of metal production. Additionally, many of the materials used in wall panels are recyclable.

Applications des profileuses de panneaux muraux

It is used in various industries to produce panels for different applications:

1. Residential Construction

These machines manufacture metal wall panels used in homes, ensuring durability and aesthetic appeal. Steel and aluminum panels are commonly used for exterior walls and roofing.

2. Commercial and Industrial Buildings

Factories, warehouses, and office buildings often use metal wall panels for structural strength and fire resistance. Roll forming machines help produce panels that meet industry standards for safety and durability.

3. Prefabricated Structures

Prefabricated houses and portable buildings rely on lightweight yet strong wall panels. The use of roll-formed panels speeds up construction and improves efficiency.

4. Cold Storage Facilities

The insulation properties of metal panels make them ideal for cold storage warehouses. These produces panels that maintain temperature control in refrigerated spaces.

5. Agricultural Structures

Barns, livestock shelters, and greenhouses require durable and weather-resistant wall panels. Roll-formed panels offer excellent protection against harsh environmental conditions.

Choisir la bonne profileuse de panneaux muraux

Selecting the right wall panel roll forming machine depends on several factors:

- Panel Design Requirements: Ensure the machine can produce the desired panel profiles.

- Compatibilité des matériaux : The machine should handle the type and thickness of metal required for production.

- Production Speed: Consider the machine’s speed to meet project deadlines efficiently.

- Automation and Control Features: A PLC-controlled machine provides better accuracy and ease of operation.

- Durabilité et entretien : Choose a machine made from high-quality materials with minimal maintenance requirements.

Investing in the right machine will enhance production efficiency and improve the quality of finished wall panels.

Conclusion

A wall panel roll forming machine is an essential tool in modern construction and manufacturing, offering a fast, precise, and cost-effective method for producing metal wall panels. With benefits such as high efficiency, consistent quality, and design versatility, this machine plays a vital role in various industries, from residential construction to industrial applications.

By understanding its working principles, key components, and applications, businesses can make informed decisions when investing in a roll forming machine. As technology advances, these machines continue to improve, providing better performance and expanding possibilities for innovative wall panel designs.