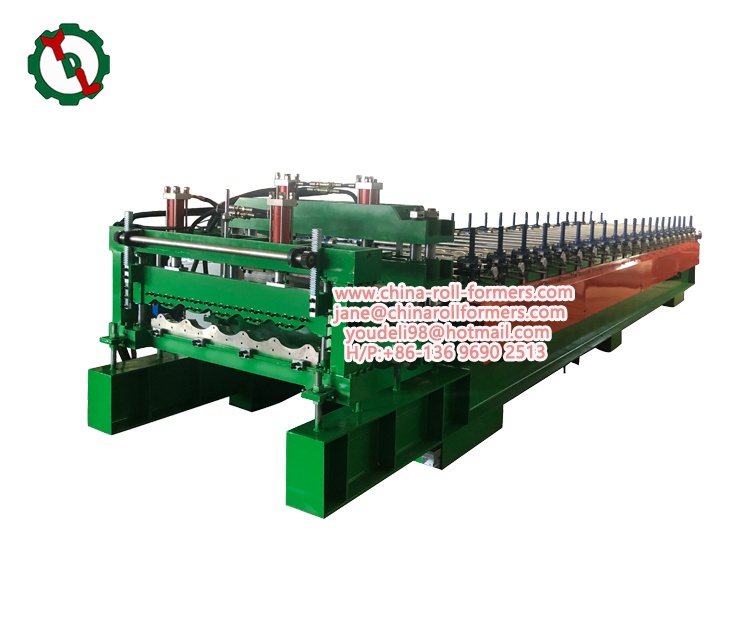

Machine de formage de rouleaux de tuiles en gradins

A new, innovative product will change the face of the roofing industry, and this is the Machine de formage de rouleaux de tuiles en gradins with Automatic Adjusted Thickness Gap. This product is designed for faster installation of roofs, better productivity, and accurate results in the process of roof installation. It has automatic thickness gap adjustment to ensure the precise layout of the tile, thereby reducing the chances of mistakes. With strength and durability, this product assures delivery even in the most demanding roofing applications. It comes in a simple-to-use package, making it ideal for both experienced and rookie roofers. The Step Tile Roofing Machine with Automatic Adjusted Thickness Gap enables one to do roofing projects very fast and accurately. The purpose of developing a new step tile roofing roll forming machine is to make the production of step tiles faster and more efficient. This machine has several features through which efficiency can be improved while uniform quality is guaranteed in every tile produced.

The primary characteristics of the machine shall be its automatic thickness gap adjustment technology. To ensure that each tile is created to the exact specifications needed, this technology automatically modifies the distance between the rollers and hence in a consistent and uniform finish. The machine is fitted with a variety of sensors which are monitoring the production process and will notify the operator in case of any problem or fault, thus reducing downtime and maintaining output.The step tile roofing roll forming machine offers many settings that one can change to fit their needs. The size, shape, and pressure of the rollers can be adjusted, besides the size and shape of the tiles created.

The step tile roofing roll forming machine is ready to change the process of making step tiles for roofs because of its advanced features and flexible choices. This tool gives a fast, good, and high-quality answer for all your step tile roof needs, whether you are a skilled roofer or a DIY lover.

Tiles are an accepted and age-old approach to roofing. The step tile, known popularly as the Spanish tile, is the tile type with the most pronounced S-shaped profile. A step tile roofing machine will, however, be able to make this very tedious and complicated process of making step tiles much easier. A step tile roofing machine is specifically designed to produce step tiles in a uniform and efficient manner. The rollers and pressers of these machines usually cooperate to give the required shape to the tile and press it into the mold. An important feature of a step tile roofing machine is its ability to automatically adjust the thickness gap between the rollers for more precision and control over the end product.

It is important for the automatic thickness gap adjustment to make sure that the machine produces tiles of equal size and shape throughout. This is important both practically and aesthetically—crooked tiles or the wrong dimensions can block water drainage and lead to leaks and other problems. A step tile roofing machine shall help ensure that the completed roof is beautiful, strong, and durable by removing this variable and providing an uncompromising quality final result. Another huge plus for a step tile roofing roll forming machine is its adaptability. Step tiles can be made using these machines from all sorts of materials, like clay, concrete, and metal. Also, they can be used to make tiles in many colors and finishes, which brings more customization, plus design and aesthetic freedom.

Certainly, the tile roofing roll forming machine requires proper care and maintenance to function just like any other type of machine. The equipment has to be kept in good operating condition through regular maintenance and cleaning, and operators must be trained for effective and safe use. In addition, a step tile roofing machine may serve as an excellent opportunity for any roofing contractor if handled with due care and attention.

Specification of Step Tile Roofing Roll Forming Machine

| Objet | Spécifications |

|---|---|

| Taille | 10000×1600×1400mm |

| Poids | 10000KGS |

| Servomoteur pour l'entraînement | 11KW |

| Hydraulic Cutting Power | 11KW |

| Tension | 220V / 60HZ / 3PH |

| Étapes de formation | 20 steps |

| Vitesse de travail | 3-5 m/min (excluding cutting time; depends on tile length) |

| Roof Height | 38.5mm |

| Tile Step Stamping | 10mm, 12mm, 15mm |

| Tile Step Distance | 300 mm à 600 mm |

| Minimum Head Length | 10mm |

| Minimum End Length | 50 mm |

| Largeur effective de la couverture | 1005mm |

| Largeur du matériau d'alimentation | 1220mm |

| Steel Thickness | 0.30–0.60mm (PPGI, GI Steel ≤ G550 for straight rib; GI Steel ≤ G300 for step tile) |

| Cutting Tolerance | ±2mm |

| Roofing Width Tolerance | ±5mm |

| Matériau du rouleau | Gear steel with heat treatment, CNC fine machining, polishing, and hard chrome plating (30-50μm) |

| Shaft Material | High-grade 45# forged steel |

| Shaft Diameter | 85 mm |

| Sprocket Wheel | 45# steel with high-frequency quenching |

| Cut-off System | Hydraulic automatic cutting |

| Blade Material | SKD-11 steel |

| Machine Frame Material | Fine-welded structural steel |

Product View of Step Tile Roofing Roll Forming Machine