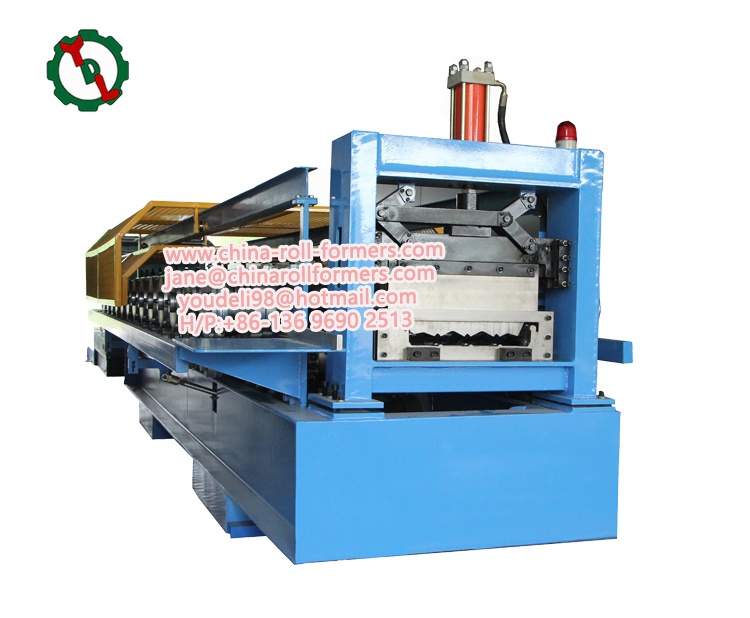

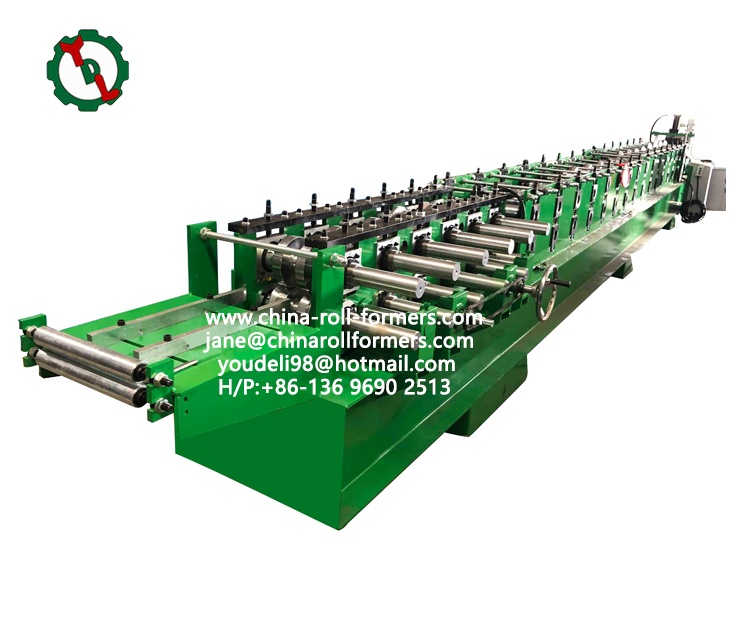

1. Introduction to Double Layer Roll Forming Machine

The double layer roll forming machine is an advanced manufacturing system designed to produce two different types of metal sheets or profiles using a single machine. This highly efficient and space-saving equipment is widely used in the construction and roofing industries, where versatility and cost-effectiveness are critical. By integrating two forming stations within one frame, it allows manufacturers to switch between profiles quickly without requiring additional equipment.

As industries continue to demand greater efficiency and flexibility, it has become an indispensable solution for businesses looking to maximize productivity while reducing operational costs. This article will explore its key features, working principles, applications, and benefits in detail.

2. Key Features of Double Layer Roll Forming Machine

It is built with state-of-the-art technology to ensure precision, speed, and durability. Some of its standout features include:

- Dual-Profile Forming Capability

The machine is capable of producing two distinct metal sheet profiles, such as trapezoidal roofing sheets and corrugated panels, by utilizing an upper and lower roll forming system. - Automatic Profile Switching

Operators can switch between the two profiles seamlessly without the need for tool changes, thanks to the automated control system. - High-Speed Performance

Equipped with precision rollers and a powerful hydraulic cutting system, the machine ensures fast production speeds while maintaining accuracy in shape and dimensions. - Durable Frame and Components

The robust structure, often made of heavy-duty steel, ensures long-term durability and resistance to wear and tear. - User-Friendly Control Panel

The machine is integrated with a PLC (Programmable Logic Controller) system, allowing for easy operation and real-time monitoring of production. - Customization Options

Manufacturers can customize the machine to produce different sheet widths, thicknesses, and profiles based on project requirements.

3. How the Double Layer Roll Forming Machine Works

The double layer roll forming machine operates through a series of precisely engineered steps to transform raw metal coils into finished panels. The working process can be outlined as follows:

- Material Feeding

The process begins by feeding the raw metal coil (galvanized steel, aluminum, or color-coated steel) into the machine. The material passes through the decoiler, which unrolls the sheet smoothly. - Roll Forming Process

The sheet enters the roll forming section, where it is gradually shaped through a sequence of roller dies. The rollers are designed according to the required profile specifications, ensuring a consistent and accurate shape. - Profile Selection & Switching

Depending on the product requirements, operators can select the desired profile (upper or lower layer) via the control panel. The hydraulic switching system automatically shifts between the two layers without manual intervention. - Cutting & Finishing

Once the sheet reaches the desired length, the hydraulic cutting system trims it to size with high precision. This ensures clean, burr-free edges that meet quality standards. - Stacking & Output

The finished sheets are then stacked for packaging and transportation. The machine’s automatic stacking system helps streamline the handling of finished products.

4. Applications of Double Layer Roll Forming Machine

It is widely used across various industries, particularly in construction and infrastructure development. Some of its key applications include:

- Roofing Sheet Production

One of the primary uses of this machine is manufacturing metal roofing sheets, including trapezoidal, corrugated, and standing seam panels. - Wall Cladding Production

The machine is also used to produce wall panels for industrial, commercial, and residential buildings. - Structural Decking Sheets

Many construction projects require steel decking sheets, which can also be manufactured using this machine. - Prefab Building Components

Pre-engineered buildings (PEB) and prefabricated homes often utilize roll-formed panels, making the double layer roll forming machine an essential piece of equipment. - Garage & Storage Sheds

The machine can produce sheets used in building garages, warehouses, and storage facilities.

5. Advantages of Using a Double Layer Roll Forming Machine

Businesses that invest in a double layer roll forming machine gain several advantages, including:

5.1 Increased Productivity

The ability to switch between two different profiles without stopping production significantly enhances efficiency. This feature minimizes downtime, allowing manufacturers to meet high-volume demands with ease.

5.2 Space-Saving Design

Instead of using two separate machines for different profiles, a double layer roll forming machine integrates both functions into a single compact unit. This optimizes factory space and reduces equipment costs.

5.3 Cost Efficiency

Since a single machine performs the work of two, businesses save on initial investment, maintenance costs, and energy consumption. Additionally, reduced labor requirements contribute to overall cost savings.

5.4 High Precision & Quality

Advanced roll forming technology ensures that every sheet produced meets stringent quality standards. Consistency in shape, thickness, and size is maintained across all batches.

5.5 Low Waste Generation

The precision cutting and forming process minimize material wastage, making production more sustainable and cost-effective.

5.6 Versatility & Customization

Whether producing sheets for commercial buildings, residential homes, or industrial projects, the machine can be customized to accommodate different materials, thicknesses, and profiles.

5.7 Durability & Long Lifespan

Built with heavy-duty materials and equipped with high-performance components, they offers excellent durability and a long operational life.

6. Choosing the Right Double Layer Roll Forming Machine

When selecting a double layer roll forming machine, businesses should consider the following factors:

- Production Requirements: Determine the required sheet profiles, thickness, and production capacity.

- Machine Quality & Brand Reputation: Choose a manufacturer known for producing high-quality and reliable machines.

- Automation & Control System: Look for a machine with an advanced PLC system for seamless operation.

- Customization Options: Ensure the machine can be tailored to meet specific project needs.

- After-Sales Support & Warranty: Opt for a supplier that provides excellent customer service, maintenance support, and warranty coverage.

7. Conclusion

The double layer roll forming machine is a game-changer in the metal sheet manufacturing industry. Its ability to produce two different profiles within a single compact system makes it an ideal choice for businesses seeking high efficiency, cost savings, and superior product quality. Whether for roofing, wall cladding, or industrial applications, this machine provides a reliable and versatile solution for modern construction needs.

For manufacturers looking to enhance productivity and optimize costs, investing in a double layer roll forming machine is a strategic move that ensures long-term success. With its advanced technology, user-friendly design, and durable construction, this machine is set to play a crucial role in the future of roll forming production.