In the world of metalworking and construction, a Walzprofiliermaschine für Verkleidungen plays a critical role in shaping and forming metal into the desired profile. These machines are primarily used for producing cladding materials for buildings, roofs, and walls. Cladding is a key component in both the aesthetic and functional aspects of modern construction, and roll forming provides a highly efficient method for producing these materials. But what exactly is this machine, and how does it contribute to construction projects? Let’s explore its function, benefits, and applications.

Verständnis für Verkleidungsrollformmaschinen

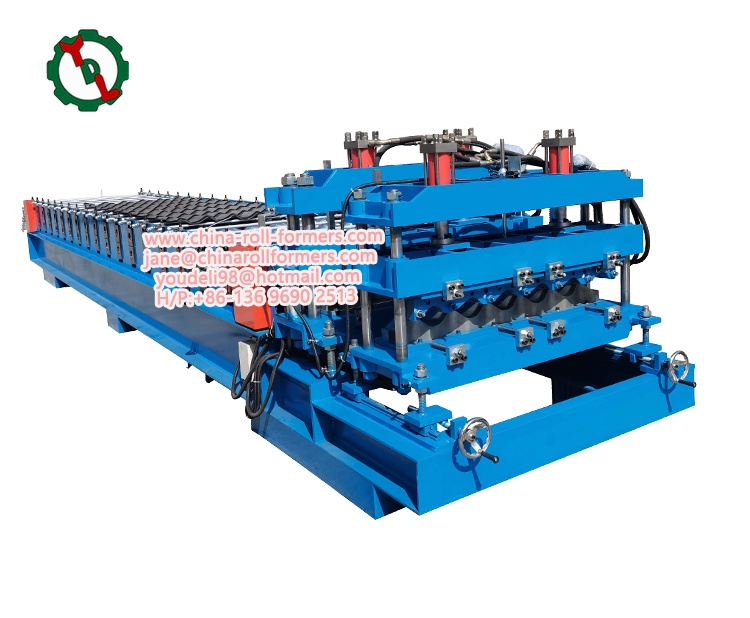

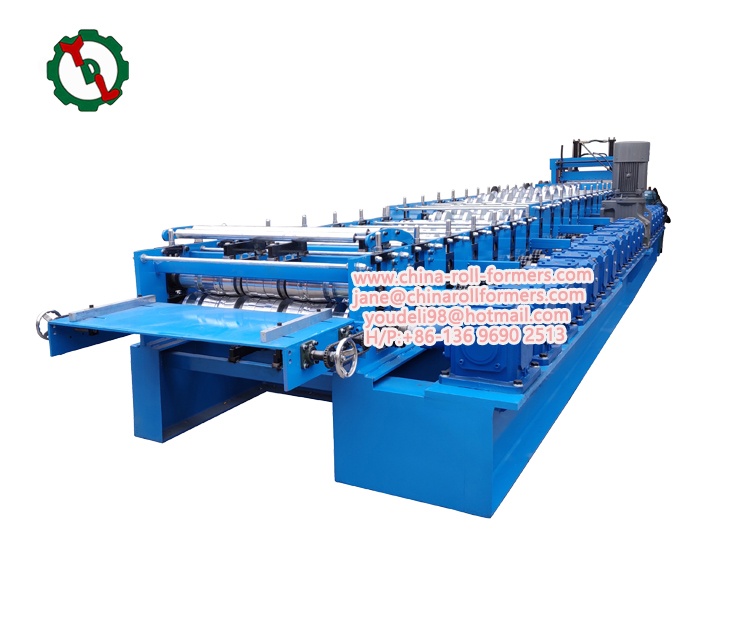

A cladding roll forming machine is an industrial machine used to shape metal sheets into cladding panels. The process involves feeding metal strips, usually made from steel or aluminum, through a series of rollers. These rollers progressively shape the metal into a predetermined profile, such as standing seam panels, corrugated sheets, or trapezoidal profiles.

Roll forming is a continuous process that makes it possible to produce long sections of cladding panels with consistent dimensions and high precision. The finished panels are then used for exterior wall coverings, roofing materials, or even decorative features on buildings.

The basic components of such a machine include a decoiler, roll forming rollers, a cutting system, and a control panel. Each of these parts ensures the quality and precision of the final product.

Key Features and Advantages

- Präzision und Konsistenz: The primary advantage of a cladding roll forming machine is its ability to produce highly precise and consistent profiles. Whether it’s a long continuous roof panel or a series of wall cladding sheets, the machine ensures uniformity throughout the production process, reducing waste and errors in construction.

- Hohe Produktionsgeschwindigkeit: Roll forming machines are known for their high-speed production capabilities. Once the setup is complete, these machines can run continuously, producing large quantities of cladding panels in a short period. This is particularly beneficial in large construction projects where time is of the essence.

- Vielseitigkeit im Design: They can be designed to produce various profiles to suit different architectural styles. From simple flat sheets to complex curved or textured designs, these machines offer great flexibility in creating different types of cladding materials.

- Durability and Strength: The metal used in cladding is typically galvanized or coated to enhance its durability, resistance to weathering, and strength. Roll forming ensures that the metal retains its structural integrity, making it suitable for long-lasting applications in both residential and commercial buildings.

- Reduced Material Wastage: The precise nature of the roll forming process means less material waste. As the machine shapes the metal sheet without the need for cutting, the material is used more efficiently, resulting in fewer off-cuts and scraps.

Anwendungen von Verkleidungsrollformmaschinen

They are used in a variety of applications across different industries. Below are some of the most common uses:

1. Roofing Materials

One of the most significant applications of a cladding roll forming machine is in the production of roofing sheets. These machines create profiles that are designed to be weather-resistant, lightweight, and easy to install. The use of cladding panels for roofing ensures a durable, low-maintenance solution that protects buildings from environmental elements.

2. Wall Cladding Panels

Metal cladding is a popular choice for building facades due to its modern appearance and durability. They are used to create decorative and protective wall panels that add aesthetic value and enhance the building’s insulation and resistance to external conditions.

3. Insulated Panels

In addition to producing standard cladding panels, some roll forming machines are capable of manufacturing insulated panels. These panels consist of a layer of insulation material sandwiched between two metal sheets, offering enhanced thermal efficiency for building exteriors.

4. Structural Components

Beyond cladding, roll forming machines are also used to produce other structural components for buildings. This includes framing members, beams, and columns that form the skeleton of a building, often fabricated from galvanized steel for added strength.

5. Architectural Features

In some cases, they are employed to create customized architectural features. These can range from decorative panels and finishes to functional elements like sunshades or rainwater channels that improve the building’s performance and visual appeal.

How a Cladding Roll Forming Machine Works

The operation of a cladding roll forming machine is based on the principle of continuous metal shaping. The process typically begins with the material being unrolled from a coil. This coil is then fed into the roll forming machine, where it passes through a series of rollers. Each roller progressively shapes the metal until it reaches the desired profile.

At the final stage of the process, the machine may include a cutting system that cuts the cladding panels to the specified length. This is usually done using a flying shear, which cuts the material while it is still moving through the machine, maintaining a high level of productivity.

The roll forming process is continuous, meaning that the machine can operate without stopping, making it an excellent choice for large-scale production. Additionally, the machine is controlled via a PLC (programmable logic controller) that ensures accuracy and automation throughout the process.

Maintenance and Care for Cladding Roll Forming Machines

Proper maintenance of a cladding roll forming machine is essential for ensuring its longevity and consistent performance. Regular checks on the rollers, alignment, and the cutting system should be performed to avoid unnecessary downtime. Lubrication of the machine components and cleaning of the equipment are also important steps in keeping the machine running smoothly.

Investing in high-quality materials and parts will reduce wear and tear on the machine, and in turn, minimize maintenance costs in the long run. Operators should be trained to handle the machinery correctly, ensuring that the machine is running at optimal efficiency.

Schlussfolgerung

A cladding roll forming machine is a vital piece of equipment in the construction and metalworking industries. By efficiently shaping metal sheets into a wide variety of profiles, these machines help produce durable, aesthetically pleasing, and functional cladding materials. Whether for roofing, wall cladding, or custom architectural features, the versatility, speed, and precision of these machines make them an indispensable tool in modern construction.

With its ability to reduce material wastage, increase production speed, and offer a high level of customization, a cladding roll forming machine is a valuable asset for any construction project. Investing in a high-quality machine can significantly improve the efficiency of your operations, ultimately leading to better products and increased customer satisfaction.