When it comes to manufacturing and construction, a Bodenbelagsmaschine plays a pivotal role in the production of metal decking that forms the foundation for floors in buildings, bridges, and other large-scale infrastructure. As the demand for robust, reliable, and high-performance decking continues to grow, selecting the right equipment becomes crucial. In this article, we will highlight the top features to look for in a high-quality machine and explain why these features are essential for maximizing productivity and ensuring the longevity of the equipment.

Understanding the Floor Deck Machine

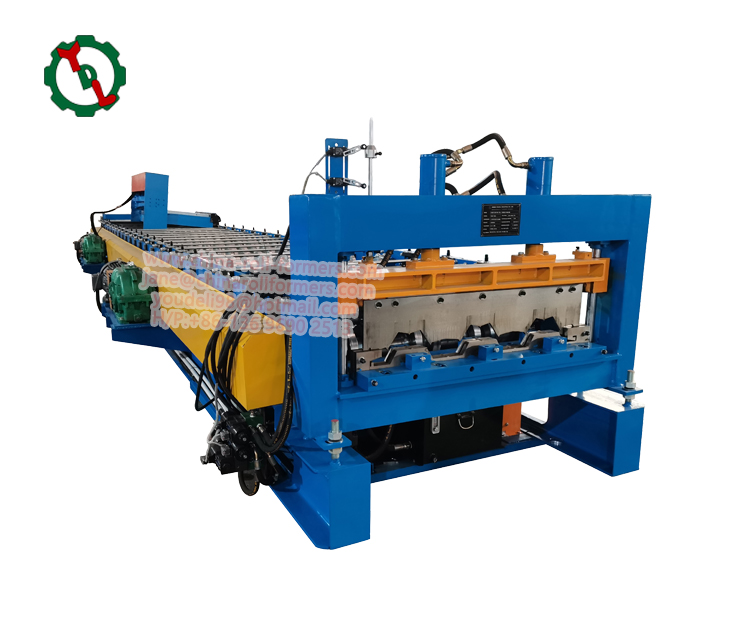

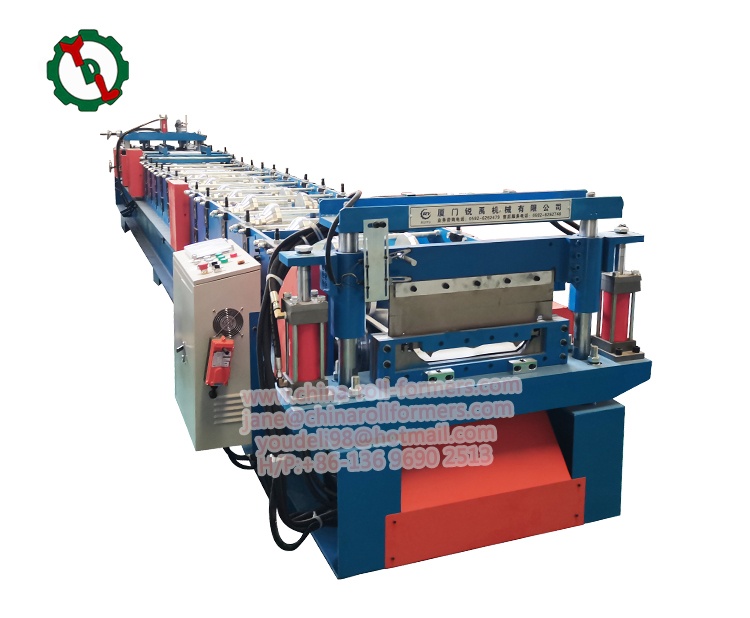

Before diving into the features, it’s important to understand the function of a floor deck machine. They are designed to form and shape steel sheets into floor decking panels. These panels serve as a support system for floors, providing a strong base for concrete or other flooring materials to be laid on. The machine uses various mechanical and hydraulic processes to form the sheets, ensuring precise, high-quality output that meets the specific requirements of the construction project.

1. Precision and Accuracy in Forming

One of the most important features of a high-quality floor deck machine is its ability to deliver precise and accurate panel formation. The machine should be equipped with advanced forming tools and components that allow for tight tolerances and consistent output. This ensures that every panel produced meets the exact specifications required for the project, reducing waste and minimizing the need for post-production adjustments.

The precision of the machine is essential for the overall integrity of the floor system. Panels that are not formed correctly can lead to structural issues or delays during construction, so accuracy is a key factor to consider when selecting it.

2. Durability and Long-Term Reliability

Durability is another crucial feature of a high-quality floor deck machine. The machine should be built with strong, high-quality materials that can withstand the rigors of continuous use in a production environment. High-quality machines are designed to operate for long periods without frequent breakdowns or excessive wear.

Machines with enhanced durability reduce maintenance costs and downtime, allowing manufacturers to maintain high production levels and meet tight project deadlines. Look for machines made with heavy-duty steel, high-performance bearings, and other components that can handle the strain of constant operation.

3. Versatility in Panel Sizes and Designs

Another important feature of a floor deck machine is its versatility in handling different panel sizes and designs. Construction projects often require various types of panels with specific dimensions, and the ability to adjust the machine to accommodate different sizes is essential for meeting diverse customer needs.

High-quality machines typically come with adjustable settings that allow for the production of panels in various widths, thicknesses, and profiles. This versatility makes it easier for manufacturers to take on a wide range of projects without the need for multiple machines or frequent retooling.

4. High-Speed Production Capabilities

In the fast-paced construction industry, speed is a critical factor. A high-quality floor deck machine should be capable of producing large volumes of panels in a short amount of time. High-speed production capabilities are especially important for manufacturers who need to meet tight deadlines or handle large-scale construction projects.

A machine with fast cycle times can produce more panels per day, increasing overall productivity and ensuring that the project stays on schedule. Additionally, machines with quick setup and changeover times allow manufacturers to adapt quickly to new project requirements without significant downtime.

5. Energy Efficiency

As energy costs continue to rise and sustainability becomes more important, energy efficiency is a feature that cannot be overlooked. A floor deck machine that operates efficiently helps reduce operational costs and minimizes the environmental impact of the manufacturing process.

Look for machines with energy-saving features such as variable speed drives, which adjust motor speeds based on demand, or hydraulic systems that optimize energy usage. These features can significantly lower energy consumption, which can lead to cost savings in the long run.

6. Advanced Control Systems

Modern floor deck machines are often equipped with advanced control systems that enable easy operation and enhanced automation. These systems typically include touch-screen interfaces, programmable logic controllers (PLCs), and real-time monitoring capabilities that allow operators to adjust settings, monitor performance, and troubleshoot issues with ease.

Advanced control systems provide greater flexibility and precision in machine operation, improving overall efficiency and reducing the risk of human error. Additionally, these systems enable manufacturers to track production data, helping them identify areas for improvement and optimize their processes.

7. Easy Maintenance and Serviceability

The ease of maintenance and serviceability is another key feature to consider when choosing a floor deck machine. Machines that are designed for easy maintenance can help reduce downtime and ensure that the equipment remains in good working condition for longer periods.

Look for machines that have accessible components for routine inspections, cleaning, and lubrication. Machines with modular designs, where parts can be easily replaced or upgraded, are also beneficial for minimizing service interruptions. Furthermore, machines with remote diagnostics or predictive maintenance capabilities allow operators to address potential issues before they result in costly repairs or downtime.

8. High-Quality Safety Features

Safety should always be a priority when selecting a floor deck machine. A high-quality machine will come equipped with various safety features to protect operators and prevent accidents during operation. These features may include safety guards, emergency stop buttons, and sensors that detect obstructions or malfunctions.

Additionally, advanced safety systems can help ensure that the machine operates within safe parameters, automatically halting production if something goes wrong. Proper training and adherence to safety standards are also essential for ensuring a safe working environment, but reliable safety features significantly reduce the risk of accidents.

9. Support for Automation Integration

As automation continues to reshape the manufacturing industry, the ability to integrate a floor deck machine with other automated systems is becoming increasingly important. Machines that support automation can streamline production processes, reduce labor costs, and improve overall efficiency.

Look for equipment that can easily integrate with automated material handling systems, robotic arms, or other production machinery. Automation can also aid in quality control by ensuring consistent results throughout the production process.

10. Kosten-Wirksamkeit

While the initial investment in a high-quality floor deck machine may be significant, it is essential to consider the long-term cost-effectiveness of the equipment. Machines that require less maintenance, consume less energy, and have faster production capabilities can offer a higher return on investment (ROI) over time.

Manufacturers should also evaluate the total cost of ownership, which includes maintenance costs, energy consumption, and any potential downtime. A machine that offers higher productivity and lower operating costs can ultimately save money in the long run.

Schlussfolgerung

In conclusion, selecting the right floor deck machine is a critical decision for manufacturers in the construction industry. By considering the top features highlighted in this article—such as precision, durability, versatility, speed, energy efficiency, advanced control systems, and safety—you can ensure that the machine you choose will meet the demands of your production environment and deliver high-quality results. Investing in high-quality machinery can improve productivity, reduce costs, and ensure the success of your construction projects for years to come.