In the realm of manufacturing structural components, the selection of the right machinery is paramount to ensure efficiency, precision, and the production of high-quality products. When it comes to C channel making machines, the decision-making process involves careful consideration of key features that influence performance and functionality. In this comprehensive guide, we will delve into the essential features to weigh when choosing a C channel making machine, shedding light on the critical aspects that manufacturers and operators should prioritize.

Introduction

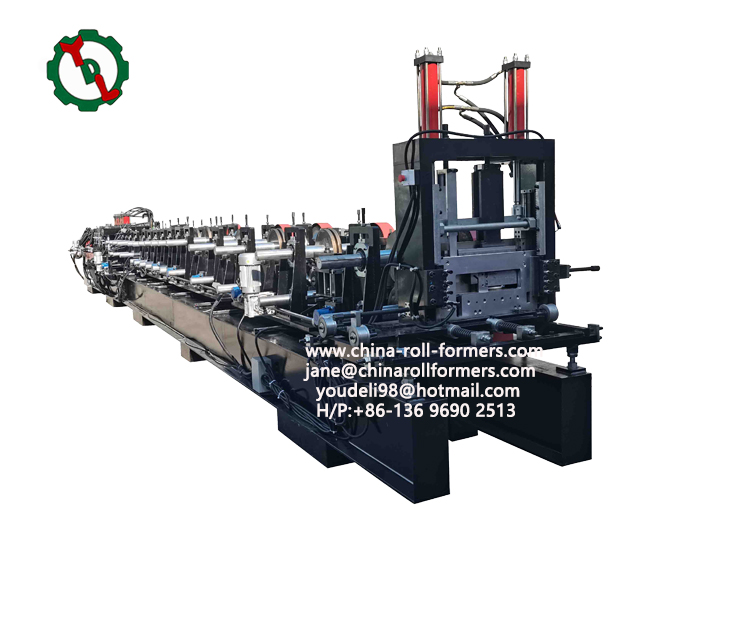

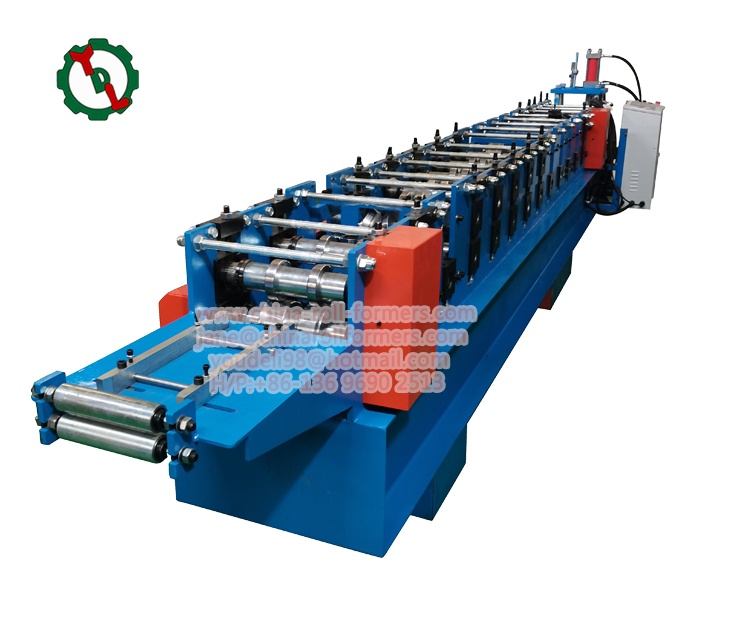

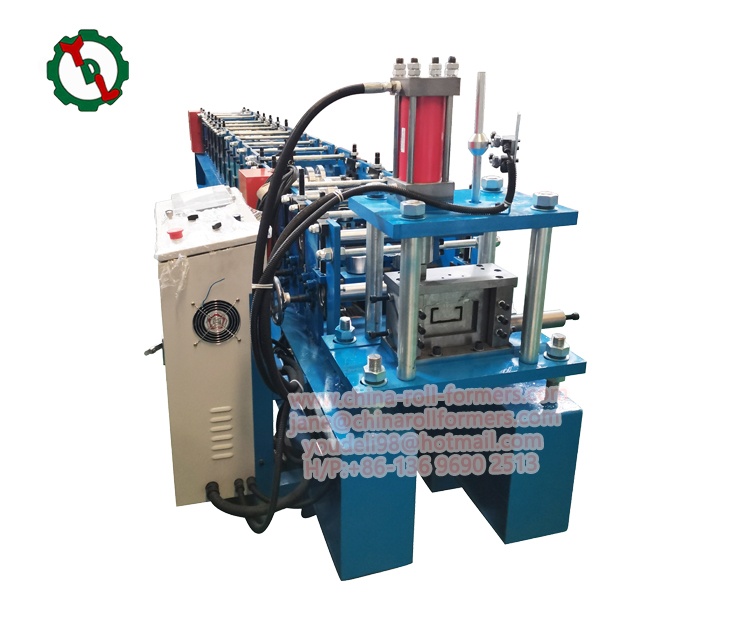

C channels, also known as structural channels, play a crucial role in various industries, providing structural support for an array of applications. The production of C channels requires specialized machinery, and the choice of a C channel making machine significantly impacts the manufacturing process. To make an informed decision, one must carefully evaluate the key features that contribute to the machine’s overall effectiveness and suitability for specific production needs.

-

Material Compatibility

One of the primary considerations when selecting a C channel making machine is its compatibility with a range of materials. The machine should be capable of efficiently processing different materials such as steel, aluminum, or other alloys commonly used in C channel production. A versatile machine that accommodates various materials ensures flexibility in manufacturing, allowing adaptation to specific project requirements and material availability.

-

Forming Speed and Efficiency

The production efficiency of a C channel making machine is closely tied to its forming speed. Manufacturers should assess the machine’s capability to achieve high production rates without compromising precision and quality. A balance between speed and accuracy is essential to meet production targets while ensuring that the formed C channels adhere to required specifications.

-

Precision and Tolerance

The precision of the C shaped steel forming machine is a critical factor in determining the accuracy and consistency of the produced channels. Tight tolerances are essential for ensuring that the dimensions of the C channels meet industry standards and project specifications. Machines equipped with advanced control systems and precision engineering contribute to the production of high-quality channels with minimal deviations.

-

Flexibility in Channel Sizes

The ability of the C channel making machine to produce a variety of channel sizes is a key feature for manufacturers catering to diverse project requirements. Whether the need is for standard sizes or customized dimensions, a versatile machine that can easily adjust to different specifications enhances its overall utility. This flexibility is particularly valuable in industries where a range of C channel sizes may be required.

-

Tooling Options and Changeover

Tooling plays a pivotal role in C channel formation, and a well-designed machine should offer a variety of tooling options. The ease of tool changeover is equally important, allowing manufacturers to transition between different channel profiles efficiently. Quick and tool-less changeover systems contribute to minimizing downtime and increasing the overall productivity of the C channel making process.

-

Automation and Control Systems

Modern C shaped steel forming machines often incorporate advanced automation and control systems. These systems enhance the machine’s overall efficiency, reduce the likelihood of errors, and provide operators with intuitive interfaces for seamless control. Features such as touchscreen controls, programmable logic controllers (PLCs), and real-time monitoring contribute to a more streamlined and user-friendly operation.

-

Durability and Build Quality

Investing in a C channel making machine with robust durability and high build quality is a prudent decision for long-term productivity. Machines constructed from quality materials and equipped with durable components are more likely to withstand the rigors of continuous production, reducing the frequency of maintenance and enhancing overall reliability.

-

Customization Capabilities

Different projects may demand unique C channel specifications, and a machine with customization capabilities becomes invaluable in such scenarios. The ability to tailor the machine settings for specific requirements, including channel dimensions, hole punching patterns, and other features, ensures adaptability to a wide range of manufacturing needs.

-

Operator Safety Features

Safety is a paramount concern in any manufacturing environment, and C channel making machines should be equipped with robust safety features to protect operators and prevent accidents. Emergency stop buttons, safety guards, and interlock systems are examples of safety features that should be integrated into the machine design.

-

Maintenance and Technical Support

A C shaped steel forming machine is a significant investment, and manufacturers should consider the availability of maintenance support and technical assistance. Opting for a machine from manufacturers or suppliers with a reputation for providing reliable support ensures that any potential issues can be addressed promptly, minimizing downtime and optimizing machine performance.

-

Cost and Return on Investment (ROI)

While upfront costs are a consideration, evaluating the long-term return on investment is equally crucial. A C shaped steel forming machine that offers a balance between initial cost, ongoing maintenance expenses, and productivity gains provides a more sustainable and economically viable solution.

-

Environmental Considerations

As environmental awareness grows, manufacturers may prioritize machines that adhere to sustainable and energy-efficient practices. Evaluating a C channel making machine’s energy consumption, waste reduction features, and adherence to environmental standards can align with the broader goal of sustainable manufacturing practices.

- Industry Standards and Compliance

Ensuring that the selected C shaped steel forming machine complies with industry standards and regulations is essential. Machines that meet or exceed safety, quality, and environmental standards provide assurance of their reliability and adherence to established benchmarks.

Conclusion

In conclusion, the process of choosing a C channel making machine involves a comprehensive evaluation of various features to align the machine with specific production requirements and industry standards. Material compatibility, forming speed, precision, flexibility, automation, durability, safety features, and environmental considerations collectively contribute to the suitability of a machine for C channel manufacturing. By prioritizing these key features, manufacturers can make informed decisions that enhance efficiency, reduce operational challenges, and ultimately contribute to the production of high-quality C channels for diverse applications.