Blog

Blog List

C-type steel channel forming machines revolutionize modern manufacturing, offering precision, efficiency, and versatility for creating essential structural components used in various industries.

- January 19, 2024

The crimping curving machine revolutionizes metal fabrication with its precision, efficiency, versatility, and eco-friendly practices, making it a cornerstone in modern metalworking.

- January 15, 2024

Selecting a C channel roll forming machine involves considering crucial features like material compatibility, forming speed, customization, automation, and tooling design. This strategic investment ensures efficiency and success in diverse metal fabrication projects.

- January 10, 2024

Standing seam profiling machines expertly handle diverse materials, from traditional metals to innovative options, enabling precise and aesthetically pleasing standing seam roofs.

- January 3, 2024

The article delves into the precision engineering and global impact of corrugated roll forming machines, emphasizing their vital role in transforming metal coils into versatile corrugated sheets across industries.

- December 27, 2023

- September 8, 2023

Crimping Rolling Curving Machines are versatile metal forming machines used to bend and shape metal sheets and plates. They utilize three main processes - crimping, rolling, and curving - to transform flat metal stock into a variety of shapes and profiles.

NEWS

Menu

Hot Product

- February 24, 2025

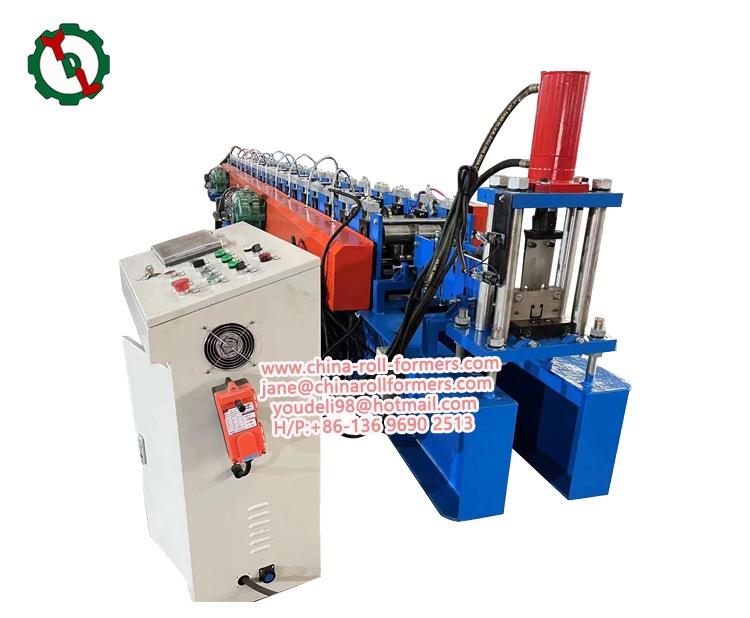

Equipment characteristics

High degree of automation: ribbed roof rolling forming machine adopts advanced automatic control system, which can realize the whole process of automatic production from coil feeding, molding, cutting to finished product output, greatly improving production efficiency.

High molding accuracy: The equipment adopts high-precision rolling mold and molding process to ensure that the ribbed roof plate produced is accurate in size and regular in shape, meeting the requirements of architectural design.

Strong adaptability: The equipment can adjust the molding mold and process parameters according to the needs of different customers, and produce roofing panels with different specifications and different rib structures, which has strong market adaptability.

Energy saving and environmental protection: ribbed roof rolling forming machine in the production process, can make full use of raw materials, reduce waste generation, while the energy consumption of the equipment itself is relatively low, in line with the energy saving and environmental protection requirements of modern manufacturing industry.

- July 7, 2023

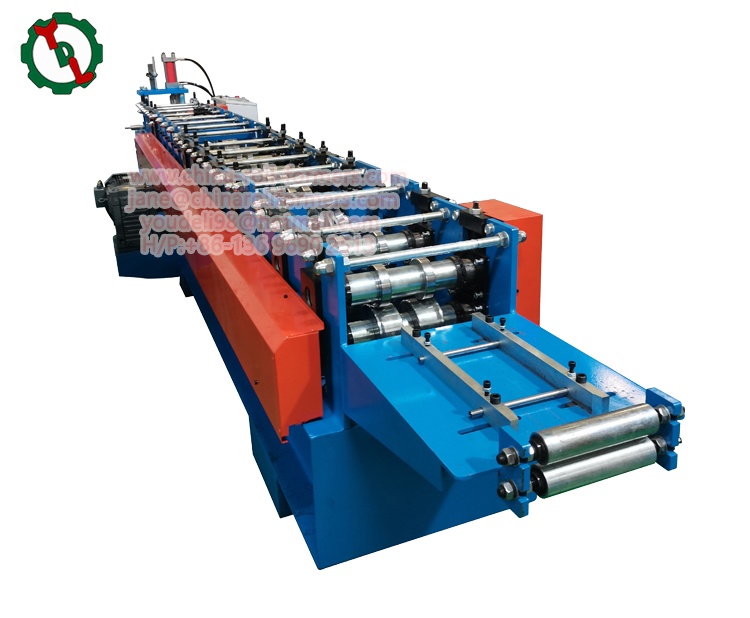

The CZ Purlin Interchanged Roll Forming Machine has a number of features that set it apart from the competition. It offers a user-friendly interface, which enables operators to quickly operate and check on the operation of the machine. Additionally, it was made using premium components to ensure lifespan and durability. The machine also uses cutting-edge technologies to boost productivity, such as PLC control systems and servo motors.