Blog

Blog List

Choosing the right standing seam curving machine involves prioritizing features like compatibility, precision, durability, and manufacturer support to ensure optimal performance and long-term success in metal fabrication projects.

- March 1, 2024

When purchasing a PU sandwich panel machine, consider key factors like production capacity, automation level, and supplier reputation to ensure optimal performance and high-quality panels.

- February 26, 2024

The evolving landscape of shutter door materials, guided by technological advancements and industry trends, empowers manufacturers to deliver doors that excel in functionality, durability, and innovation.

- February 19, 2024

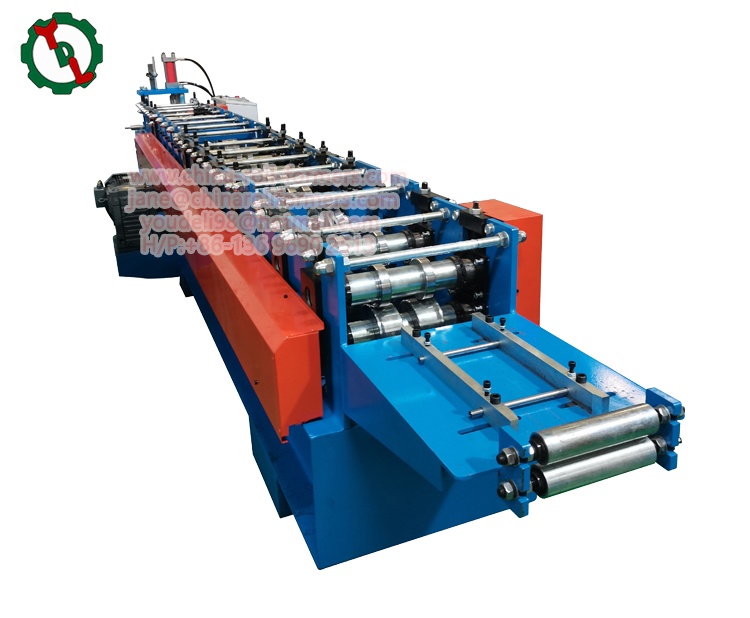

Choosing a C channel making machine involves key considerations like material compatibility, forming speed, precision, flexibility, automation, durability, safety features, and environmental adherence. These factors collectively ensure efficient and high-quality C channel production.

- February 12, 2024

The wall panel roll forming machine seamlessly combines efficiency and precision, revolutionizing the construction industry by streamlining the production of high-quality, customized wall panels for diverse applications, from residential buildings to industrial warehouses.

- February 5, 2024

Floor deck machines revolutionize construction through precision, automation, and adaptability, enhancing efficiency, safety, and sustainability in modern construction projects.

- January 25, 2024

NEWS

Menu

Hot Product

- July 25, 2023

An essential part of every building's gutter system, a downspout or downpipe is in charge of channeling rainfall away from the foundation. The Downspouts & Downpipes Roll Forming Machine is a specialist machine needed to manufacture these crucial parts.

With the help of this roll forming machine, superior downspouts and downpipes may be made from a variety of materials, such as galvanized steel, copper, and aluminum. The material is fed through a succession of rollers, which precisely shape and cut the metal to the required size and profile.

The Downspouts & Downpipes Roll Forming Machine's capacity to create an infinite length of gutter components is one of its main benefits. As a result, users may design downpipes and downspouts of any length.

- December 5, 2023

The C channel roll forming machine is fully automated and requires limited manual intervention, making it an excellent option for large-volume production. Additionally, it is equipped with sensors that detect any abnormalities, minimizing wastage.