Blog

Blog List

Choosing the right rolling shutter roll forming machine is essential for achieving efficient and high-quality production, with factors such as material compatibility, design considerations, production capacity, automation, and durability playing key roles in the selection process.

- May 15, 2024

C Purlin machines are essential in modern construction, offering efficiency, cost-effectiveness, and quality in producing C-shaped purlins for structural support.

- May 8, 2024

Standing seam profiling machines are crucial for producing standing seam panels used in roofing, offering high efficiency, precision, customization, and cost-effectiveness. They enhance the durability, weather resistance, and aesthetic appeal of standing seam roofs, making them popular in construction.

- May 1, 2024

Wall panel roll forming machines are essential tools in the manufacturing industry, used to efficiently produce high-quality metal wall panels for construction and other applications, offering benefits such as precision, cost-effectiveness, and versatility.

- April 24, 2024

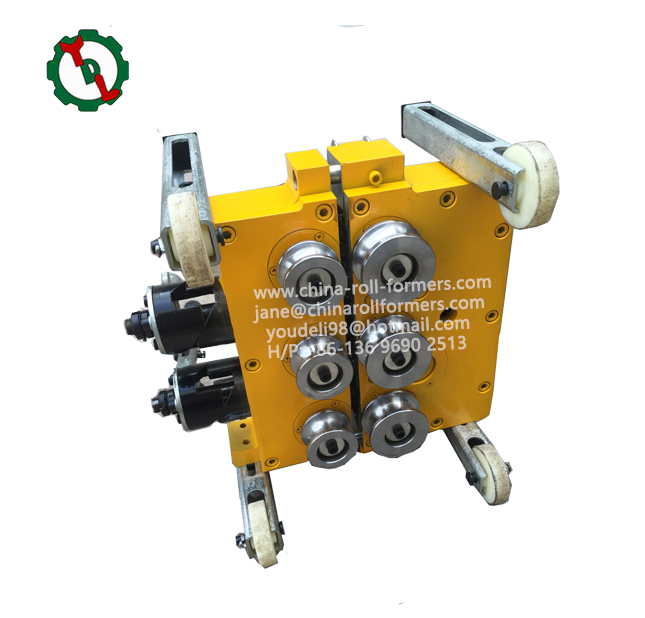

Electric seaming machines are essential equipment in various industries, providing efficient, reliable, and versatile solutions for joining materials, with benefits including high precision, durability, and cost-effectiveness.

- April 17, 2024

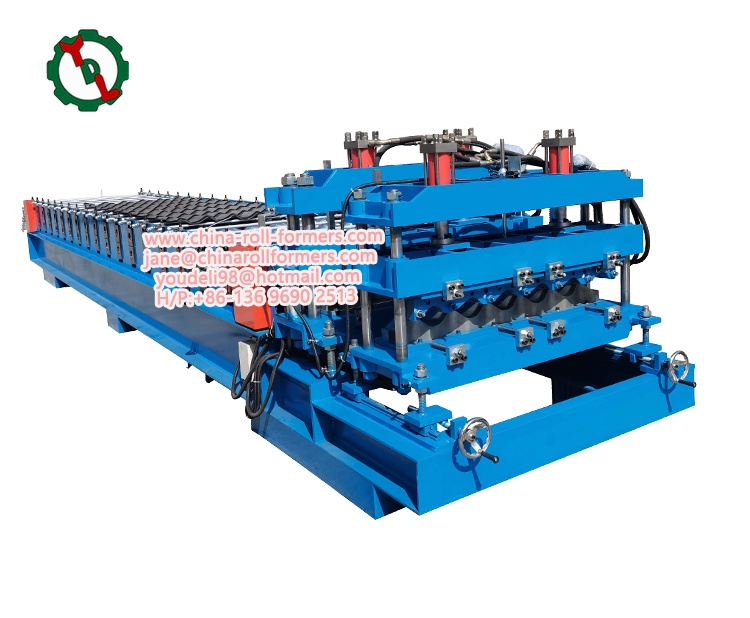

A step tile roll forming machine is a highly efficient and versatile tool used in the roofing industry to produce step tiles with consistent quality, offering manufacturers cost-effectiveness and increased productivity.

- April 10, 2024

NEWS

Menu

Hot Product

- July 25, 2023

The effectiveness of the EPE roofing laminating machine is another benefit. The device enables producers to meet production demands by quickly laminating vast amounts of roofing materials. The laminating machine is a cost-effective option for manufacturing roofing because of its speed and efficiency, which also play a key role in lowering manufacturing costs.

The EPE roofing laminating machine is user-friendly in addition to being effective and reliable. The device's easy controls and simple functioning are all part of its user-friendly design. This reduces the requirement for specialized training or technical skills by making it simple for operators to use and maintain.

- March 1, 2024

Color Steel Automatic Stacker for Double Furring Machine: A One-Stop Solution for Production Efficiency

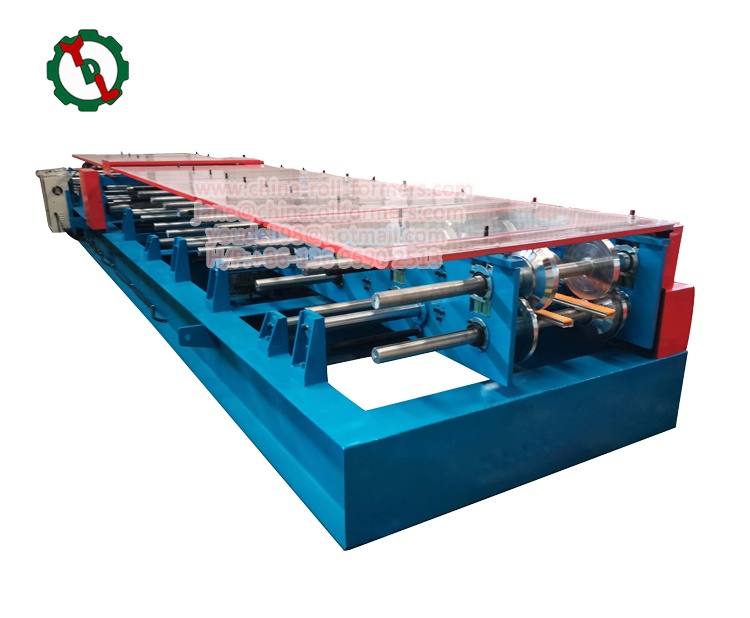

Manufacturing color steel products for wall and roof cladding is a complicated process with a range of steps and machines. One of the essential machines in the production line is the double furring machine which shapes the color steel into the required profile. However, the machine can only produce the required design and size of the product. After that, the products need to be stacked, packed, and transported to the next stage of the production line, which is a tedious process if done manually.

This is where the color steel automatic stacker for double furring machine comes in. The automatic stacker is designed to automate the process of stacking the final products from the double furring machine. The machine is designed to work seamlessly with the double furring machine, taking the finished products and stacking them in the required size and shape, ready for the next stage of the production line.