Blog

Blog List

Electric seaming machines offer enhanced precision, efficiency, safety, and versatility in industrial manufacturing, making them essential for various applications such as metal roofing, can manufacturing, and automotive components.

- July 5, 2024

This article provides an in-depth look into the operation of crimping curving machines, covering their key components, working principles, applications, maintenance, and the latest technological advancements.

- June 28, 2024

Custom roll forming machines offer significant advantages in manufacturing, including the ability to create complex shapes, high efficiency, cost-effectiveness, and versatility. These machines can revolutionize manufacturing by streamlining production, reducing waste, and improving product quality.

- June 13, 2024

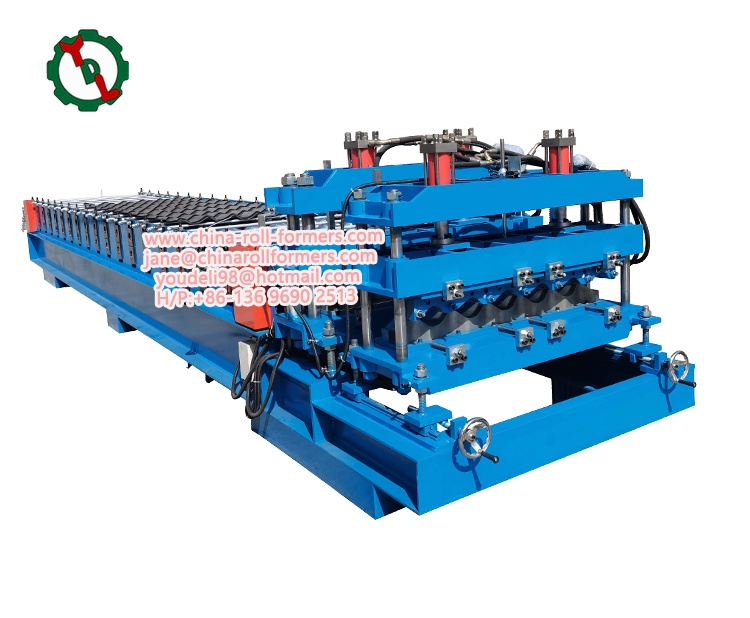

This article offers a detailed guide on step tile roll forming machines, emphasizing the importance of material selection, discussing common materials used, selection criteria, material advantages, and maintenance tips, all aimed at optimizing machine use for high-quality roofing tile production.

- June 6, 2024

Cladding roll forming machines are specialized equipment that efficiently produce metal cladding panels with precision, offering weather resistance, aesthetic appeal, and structural integrity for diverse construction needs.

- May 31, 2024

We aim to guide you in selecting high-quality shutter door machines by highlighting essential features. This guide will help manufacturers, contractors, and business owners find machines that meet their needs and enhance operational efficiency.

- May 23, 2024

NEWS

Menu

Hot Product

- February 11, 2025

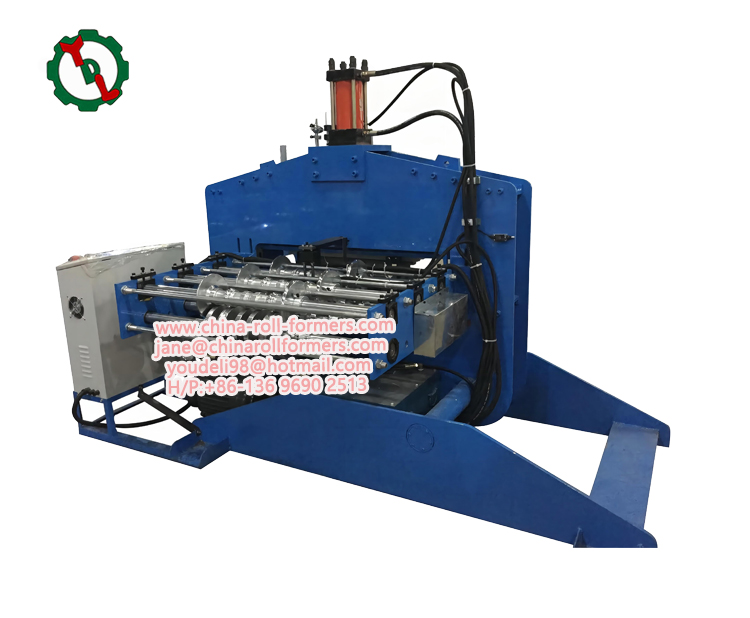

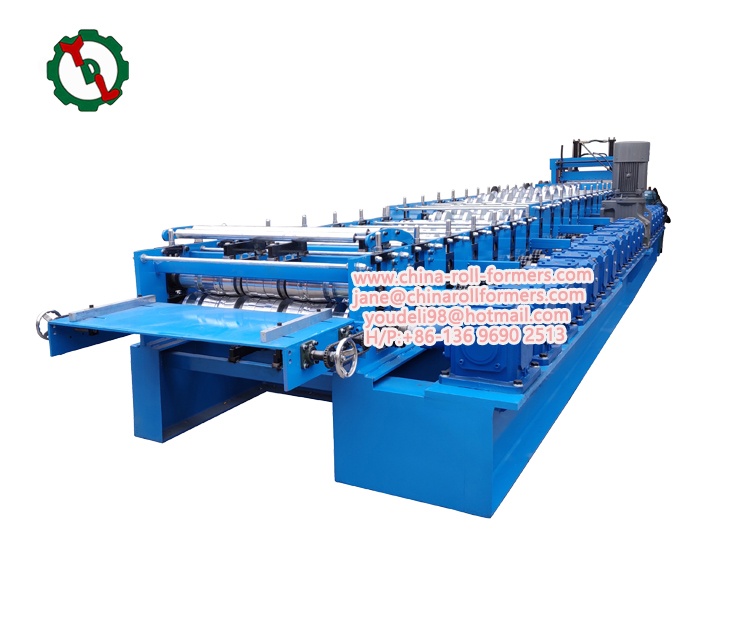

Ribbed roof sheet edge forming machine is mainly composed of edge forming system, cutting system, control system and so on. The working principle is to press raw materials (such as colored steel plates, galvanized steel plates, etc.) into roof panels with specific rib shapes through the rolling molding system, and then cut the fixed length through the cutting system, and finally realize the automatic control of the entire production process by the control system.

- July 31, 2023

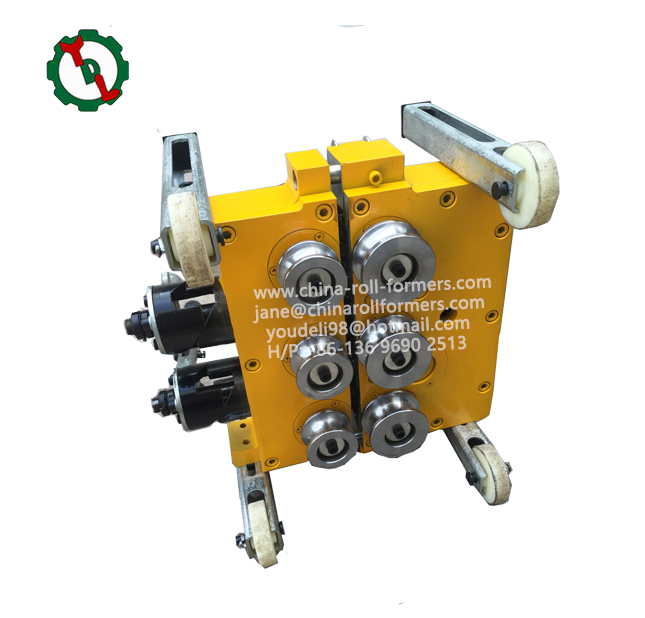

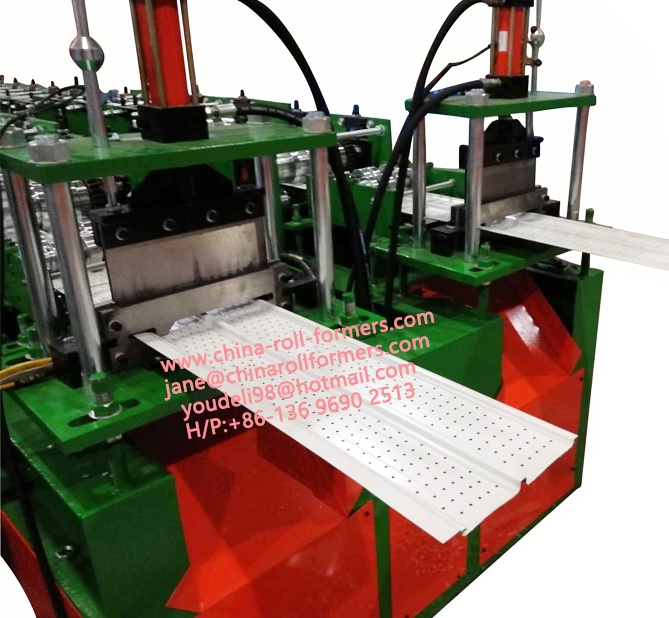

This machine differs from other roll forming machines on the market thanks to a number of its features. It has a cutting system and precise rollers that guarantee flawless and exact results each and every time. Additionally, it incorporates an adjustable punching system that enables the production of trays in a variety of forms and sizes.

The Structural Liner Tray Roll Forming Machine has a high level of automation and customization options to fulfill the requirements of contemporary production lines. It is an affordable option for organizations of all sizes because it is simple to use and needs little upkeep.

For businesses in the building, roofing, or manufacturing sectors who need top-notch structural liner trays, this machine is perfect.It can produce trays with a thickness range of 0.5mm to 1.5mm and a width range of 200mm to 480mm. Customization is also available to meet specific requirements and needs.