All Product

Welcome to explore our comprehensive product lineup featuring cutting-edge machinery like the Double Layer Roll Forming Machine, Purlin Roll Forming Machine, Electric Seaming Machine, and more. Welcome your consultation and purchase, we look forward to providing you with a quality shopping experience!

All Product List

- EPE Roofing Laminating Machine

The effectiveness of the EPE roofing laminating machine is another benefit. The device enables producers to meet production demands by quickly laminating vast amounts of roofing materials. The laminating machine is a cost-effective option for manufacturing roofing because of its speed and efficiency, which also play a key role in lowering manufacturing costs.

The EPE roofing laminating machine is user-friendly in addition to being effective and reliable. The device's easy controls and simple functioning are all part of its user-friendly design. This reduces the requirement for specialized training or technical skills by making it simple for operators to use and maintain.

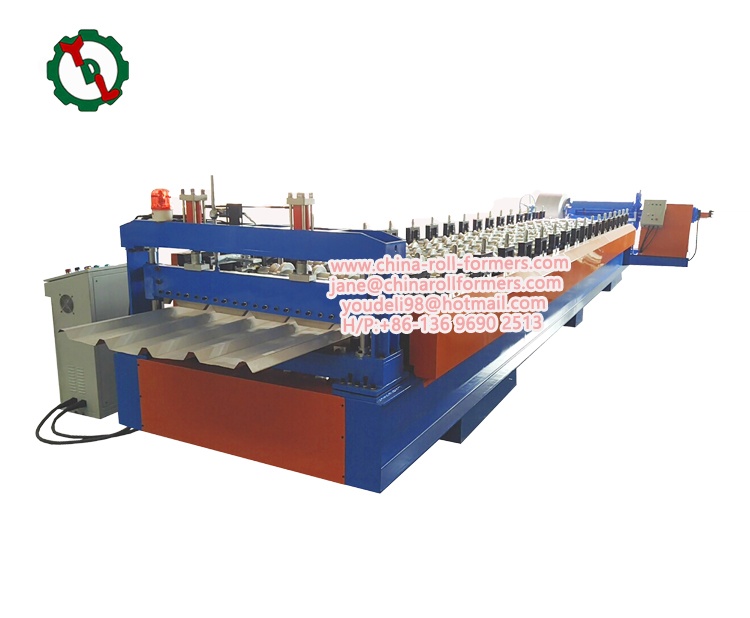

- Trapezoidal Roofing Machine

With its high-quality output and user-friendly features, the Trapezoid Roof Machine is attracting interest in the construction industry. The production of roofing sheets with trapezoidal ribs is being revolutionized by this equipment, giving roofing manufacturers a more effective and affordable option. The roll forming procedure produces roofing sheets that are uniformly sized, properly formed, and of a constant quality. The Trapezoid Roof Machine is outfitted with cutting-edge technology that improves its accuracy and dependability, such as PLC control systems and automatic cutting systems. Any roofing manufacturer aiming to maximize their revenues and optimize their production process should use this equipment.

- Crimping Curving Machine

The introduction of the Crimping Curving Machine for Standing Seam Roofing is poised to revolutionize the roofing industry. This cutting-edge machine revolutionizes the crimping and curving of panels, enabling precise bending to fit any roof design. Boosting efficiency and customization, it simplifies production and requires fewer skilled workers.

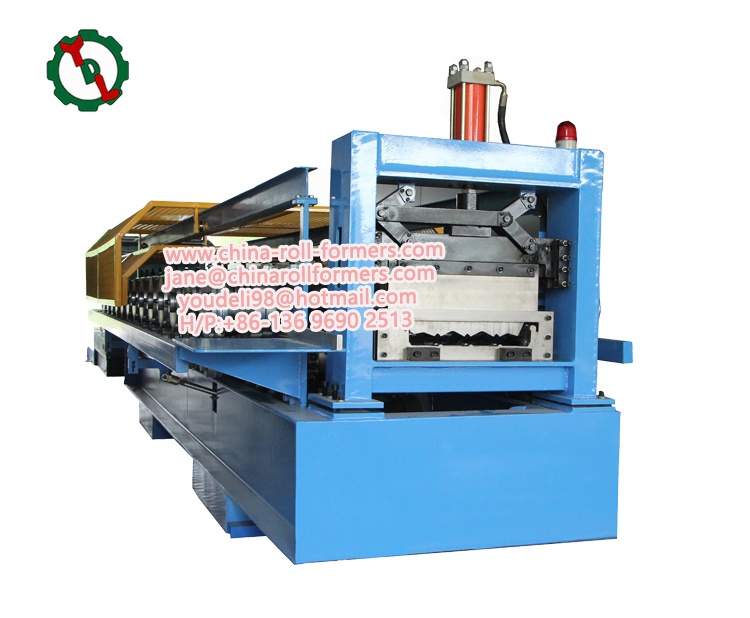

- 65MM Standing Seam Roofing Machine

High-quality standing seam roof panels can be made with the Straight & Tapered Standing Seam Roofing Machine. Because these panels are created with great care and accuracy, the end product is solid, long-lasting, and of the finest caliber. The device can easily produce both straight and tapered panels because to its versatility.

Additionally, the process will be streamlined by this roofing machine, making it quicker and more effective. As a result, roofing contractors may finish jobs more quickly and save their clients money. Modern technology is also used in the machine to guarantee that it produces panels that meet exact standards. Because of this, there is less waste, which lowers expenses for the contractor as well as the client.

Considering how simple it is to use, the Straight & Tapered Standing Seam Roofing Machine is a need for roofing professionals. The equipment is simple to use, requires little training to operate, and is made to cut down on the time and labor needed to manufacture high-quality panels. Even novice users may operate the machine effectively thanks to its straightforward controls and detailed instructions.

ion.

- Downpipes

An essential part of every building's gutter system, a downspout or downpipe is in charge of channeling rainfall away from the foundation. The Downspouts & Downpipes Roll Forming Machine is a specialist machine needed to manufacture these crucial parts.

With the help of this roll forming machine, superior downspouts and downpipes may be made from a variety of materials, such as galvanized steel, copper, and aluminum. The material is fed through a succession of rollers, which precisely shape and cut the metal to the required size and profile.

The Downspouts & Downpipes Roll Forming Machine's capacity to create an infinite length of gutter components is one of its main benefits. As a result, users may design downpipes and downspouts of any length.

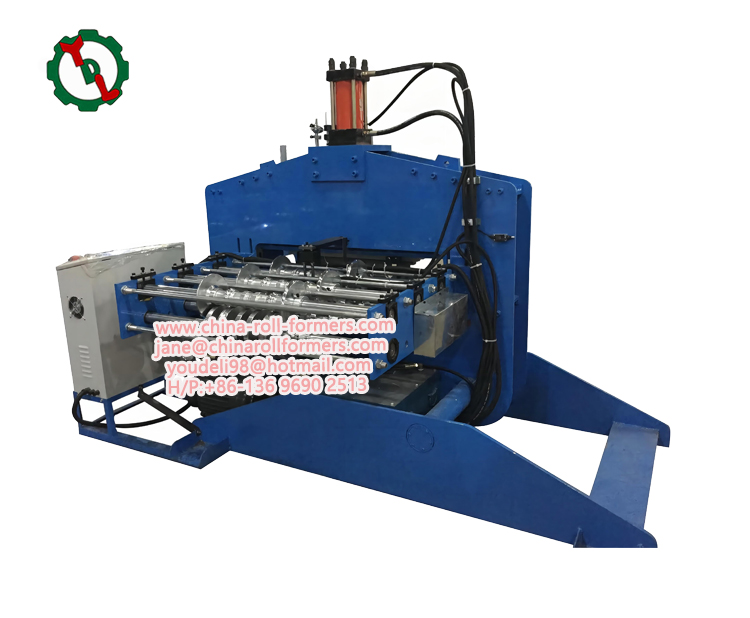

- Slitting Machine

A brand-new Automatic Shearing Slitting Line Cutting Machine has been created, and it has the potential to revolutionize the metal cutting business. This newest technology is anticipated to give manufacturing businesses aiming to transform their metalworking operations a significant boost.

The device is made to quickly and with exceptional precision cut various kinds of metal sheets. This is made possible by the Automatic Shearing Slitting Line Cutting Machine's sophisticated automated system, which guarantees that the cutting process is precise, quick, and secure. In other words, businesses can now rely on this automated procedure to streamline every aspect of their metalworking processes.

The cutting device also has an intuitive UI that makes it simple for you to manage the entire procedure. Because of this, anyone can use it regardless of their level of technical expertise. The machine is also eco-friendly for businesses because it uses less electricity and emits little carbon.

The CEO of the manufacturing company, Mr. Chen, commented on the new machine, saying: "Our main goal was to build a solution that would provide high-quality cutting, speed, and safety. With this new technology, we believe we have struck the ideal balance, and we are convinced that it will greatly benefit companies in the metalworking sector.

Product Categories

Hot Articles

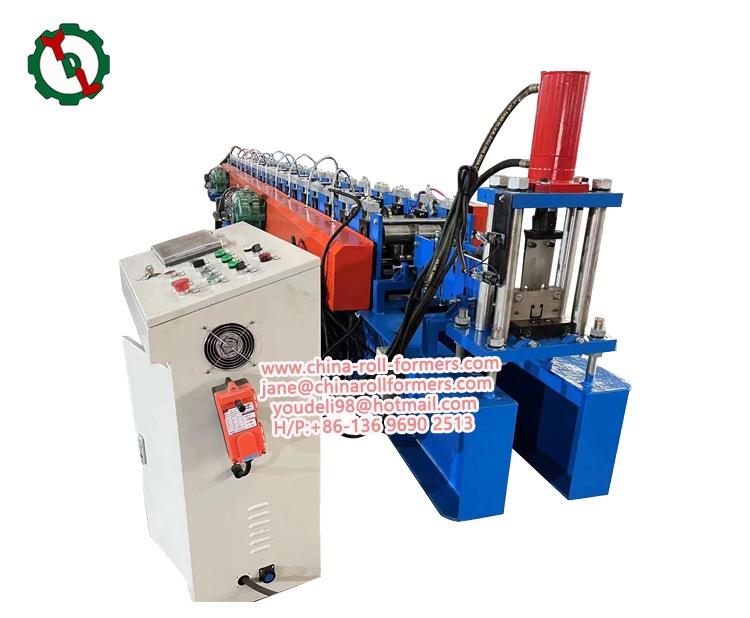

Selecting a C channel roll forming machine involves considering crucial features like material compatibility, forming speed, customization, automation, and tooling design. This strategic investment ensures efficiency and success in diverse metal fabrication projects.

- January 10, 2024

A purlin forming machine offers high precision, fast production, versatility, and automation, making it an essential tool for cost-effective and efficient purlin manufacturing in construction.

- February 24, 2025