All Product

Welcome to explore our comprehensive product lineup featuring cutting-edge machinery like the Double Layer Roll Forming Machine, Purlin Roll Forming Machine, Electric Seaming Machine, and more. Welcome your consultation and purchase, we look forward to providing you with a quality shopping experience!

All Product List

- Downpipes

You can quickly and accurately make high-quality square pipes using our square pipe roll forming machine. The machine is simple to use and needs little upkeep, making it the perfect option for small to medium-sized organizations looking for a practical way to make square pipes.

Our machine is built with high-quality materials and parts to survive even the most demanding manufacturing situations. The machine's cutting-edge technology offers precise and accurate results, and you may customize the parameters to meet your individual demands.

Additionally, our Square Pipe Roll Forming Machine is supported by first-rate technical assistance and customer care, ensuring that you have the assistance you require when you require it. Our knowledgeable staff is available to assist you with everything from product demos and training to troubleshooting and maintenance.

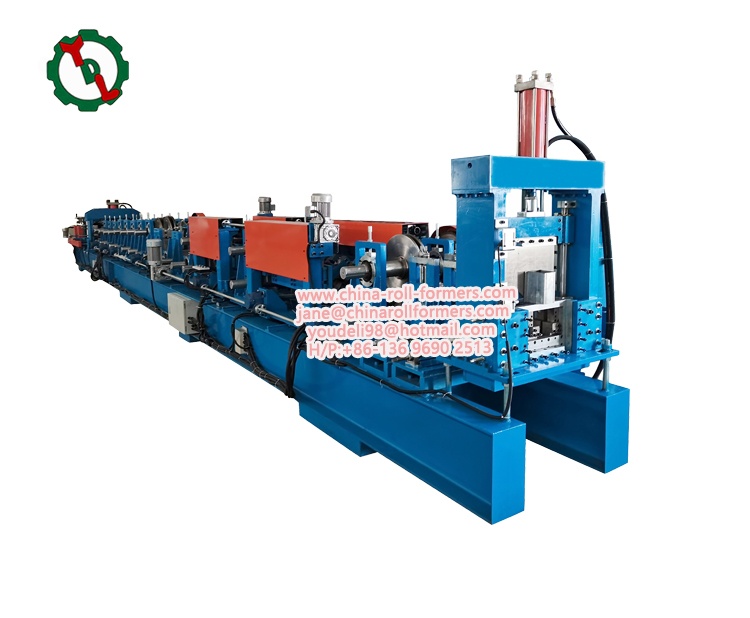

- Purlin Machine

A dependable and effective solution for steel structure requirements is constantly needed for construction and infrastructure development projects. The purlin, which is responsible for supporting the roof and wall panels, is one particular element that is crucial to these projects. The hat shape profile is one of the most common shapes for purlins, which come in a variety of sizes and shapes. The Hat Shape Purlin Forming Machine is a device created with the purpose of producing these particular purlin kinds.

A cutting-edge piece of machinery called the Hat Shape Purlin Forming Machine was created expressly to create purlins with hat-shaped profiles. Purlins of various lengths, widths, and thicknesses can be produced using this equipment to meet any construction demand. The device is highly automated, making it simple for operators to adjust and set the desired purlin dimensions accurately.

There are many benefits to using a Hat Shape Purlin Forming Machine. First off, employing this machine ensures that the purlin shape is constant, preventing changes in the profile that would impair its performance. In addition, the machine creates clean, crisp edges, making the purlins simple to install while ensuring that there are no weak places, giving them outstanding structural integrity.

The Hat Shape Purlin Forming Machine increases the productivity of fabricators. It may produce several purlins quickly, which expedites project completion. The machine is also energy-efficient, which means it uses less electricity and produces less waste. This is so that materials can be used as efficiently as possible by the Hat Shape Purlin Forming Machine.

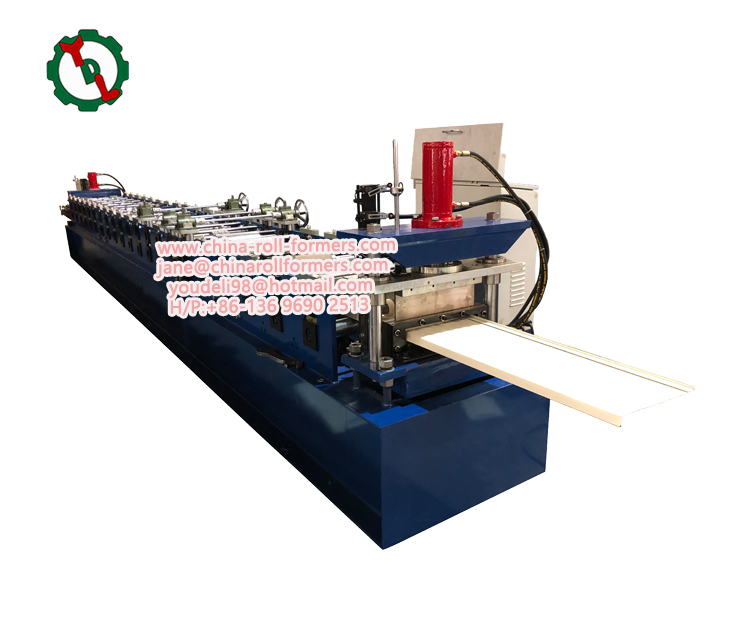

- Ridge Cap Machine

When making ridge caps, using a ridge cap machine has a number of benefits over conventional techniques. First of all, it reduces waste and saves time. Manufacturers can swiftly generate uniform ridge caps with the same size and shape by using a machine. Pre-cutting and rolling the materials also reduce waste, lowering the cost of the raw resources. Second, ridge caps produced by machines have higher-quality finishes than those produced by hand. The rolled edges have a neater, more polished appearance because they are smoother and more consistent.

A ridge cap machine is a wise investment if you want to produce ridge caps. It consistently produces high-quality goods while saving time and money. The roof is further protected by a well-made ridge cap, which also greatly enhances the roof's sturdiness, endurance, and visual appeal. As a result, any roofing manufacturer or contractor that values quality and durability and wants to produce beautiful, useful, and long-lasting roofs must have a dependable and effective ridge cap machine.

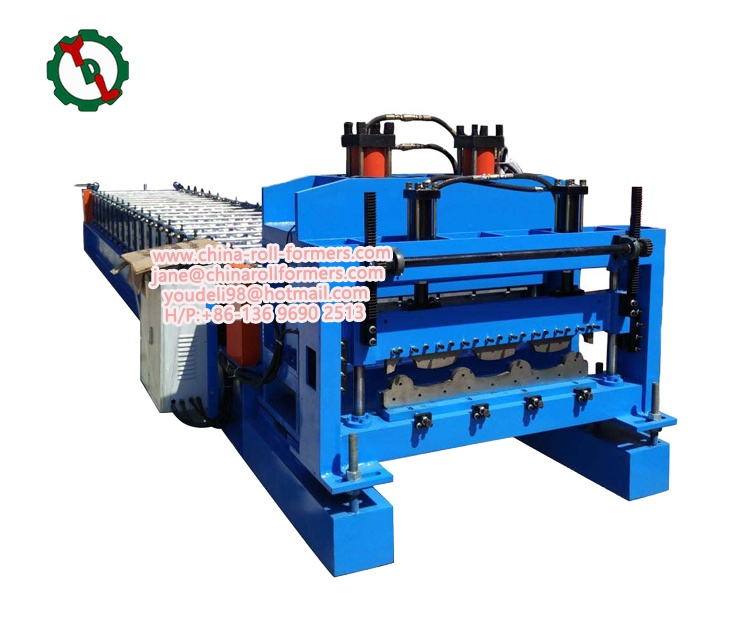

- Roofing Sheet Roll Forming Machine

One of the most important parts of any building is the roof, which shields the structure from weather conditions like rain, snow, wind, and hail. The roof must be built with high-quality components and methods to guarantee long durability and effective operation. The locking lapping method, which is popular in the construction sector, is one such method. A locking lapping roofing roll making machine is utilized to make this method easier. The interlocking panels made by the locking lapping roofing roll forming machine are perfect for roofing. Metal coils are fed through a set of rollers, which gradually shape them into the desired profile, to make the device work.

This machine creates panels with a distinctive shape that enables them to closely interlock with one another, ensuring a leak-proof and solid junction. The panels' distinctive form also makes installation simple, requiring less time and effort. The locking lapping roofing roll forming machine is offered in a variety of styles and dimensions to meet the wide range of demands of the construction sector. Snap-on standing seam, trapezoidal, and corrugated roofing panels are a few of the popular patterns. These plans can be used for both commercial and residential buildings, depending on the situation. Contractors may tailor the panels to match the specifications of certain projects thanks to the machine's ability to make them in a variety of lengths and widths.

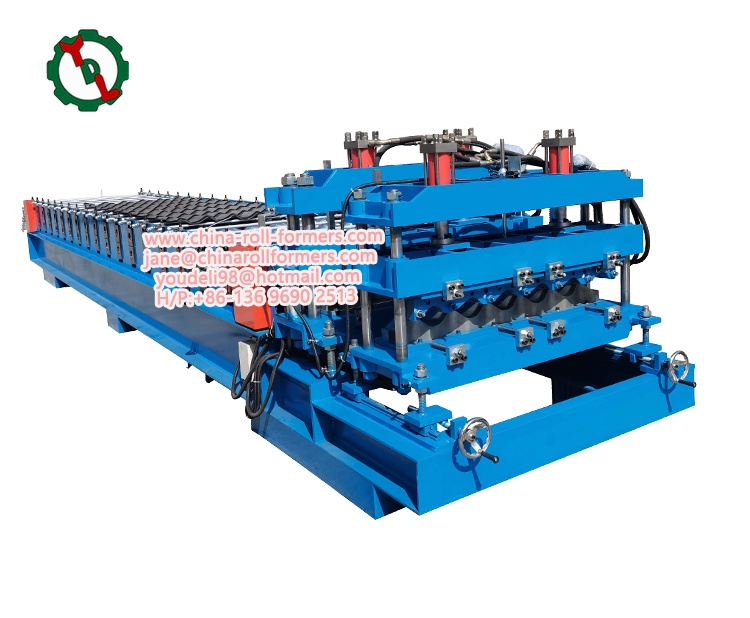

- Tile Roofing Machine

Due to its toughness and attractive appearance, tile roofing is a preferred option among homeowners. However, if you don't have access to a dependable tile roofing equipment, installing tile roofing can be difficult.

A gadget called a tile roofing machine is made to make the process of molding and shaping tile roofing sheets easier. This equipment can create premium tiles that can survive inclement weather. It is a crucial tool for skilled roofers who want to build long-lasting, high-quality roofing.

Manual labor, which can be physically and mentally taxing, is avoided by using a tile roofing machine. You will have enough roofing tiles to completely cover your roof in a short amount of time thanks to the machine's quick manufacturing capability.

- Tile Roofing Machine

Roof Tile roll forming machine: A New Technology in Roofing Industry

Metal sheets are shaped and cut into tile roofing panels using a type of roll forming equipment called a Roof Tile roll forming machine. This machine is frequently employed in the construction sector to produce roofing systems that are of excellent quality, durability, and aesthetic appeal.

The Roof Tile roll forming machine consistently shapes the metal sheets into the appropriate profile using a set of rollers. Using automatic shearing and cutting mechanisms, the machine precisely cuts the tiles to the necessary length and shape. The completed panels are then packaged and stacked for delivery to the installation location.

Product Categories

Hot Articles

A wall panel roll forming machine is a highly efficient and cost-effective tool used in construction and manufacturing to produce durable, precise, and customizable metal wall panels for various applications.

- March 14, 2025

Choosing a high-quality floor deck machine with features like precision, durability, versatility, energy efficiency, and advanced control systems ensures improved productivity, cost savings, and long-term reliability in construction projects.

- February 7, 2025