All Product

Welcome to explore our comprehensive product lineup featuring cutting-edge machinery like the Double Layer Roll Forming Machine, Purlin Roll Forming Machine, Electric Seaming Machine, and more. Welcome your consultation and purchase, we look forward to providing you with a quality shopping experience!

All Product List

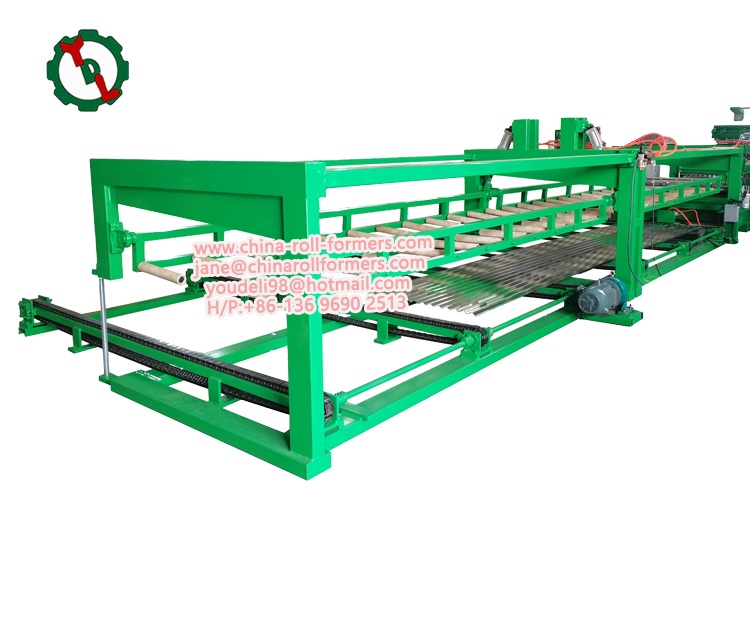

- Automatic Stacker

The automatic stacker makes excellent use of modern technologies to stack items quickly and efficiently. It not only dramatically boosts output but also cuts down on the hours of manual labor required. Employees are given a safer and more welcoming working environment as a result.

This robotic stacker's capability to handle unusual shapes and sizes with ease is one of its most noteworthy qualities. It is made to adapt to various arrangements and maintain a regular stacking pattern that maximizes space usage. The production processes of manufacturers can be improved in terms of flexibility, precision, and efficiency thanks to this machine.

- Automatic Stacker

The functionality of these machines has been revolutionized by the introduction of a new Automatic Stacker for Double Furring Machines. The stacker, which can easily handle even the largest loads and is designed to streamline processes and boost efficiency, is the ideal complement to any production plant.

A sophisticated computer system that may be programmed to do a wide range of functions is included with the stacker. It is a great option for businesses trying to increase production and cut costs because it is simple to use and requires little training.

Numerous safety elements on the Automatic Stacker are also provided to guarantee worker safety while using the equipment. These comprise sensors that are capable of seeing any unexpected activity and instantly shutting down the system to avoid accidents.

- Downpipes

The horizontal metal (often aluminum) component of the system known as gutters is typically put along the roof's eave margins or along roof features like dormers. Rainwater streaming from the roof is caught by open gutters, which route it into the downspouts.

The horizontal metal (often aluminum) component of the system known as gutters is typically put along the roof's eave margins or along roof features like dormers. Rainwater streaming from the roof is caught by open gutters, which route it into the downspouts.

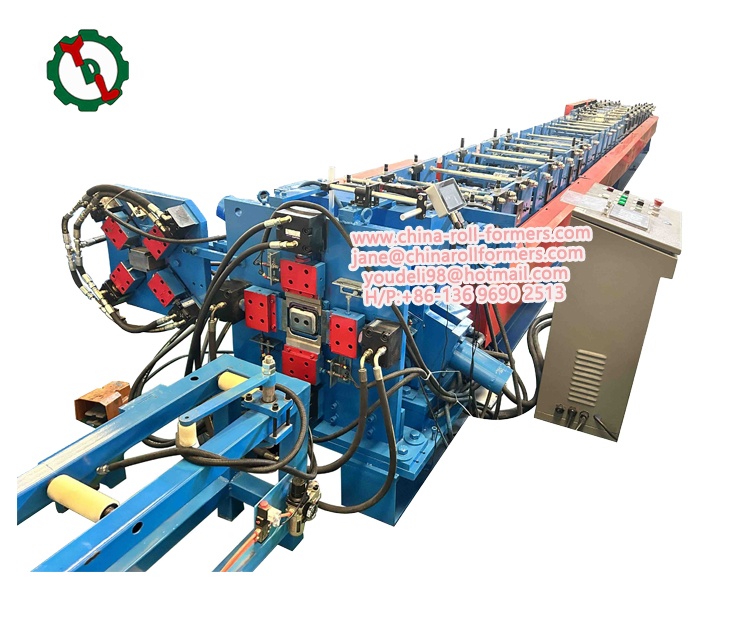

- Floor Decking Roll Forming Machine

For industrial and commercial structures, tough, long-lasting raised floor decks are made using cutting-edge steel floor decking roll forming machinery. These tools are employed in the building sector to produce a variety of waterproof, fireproof, and energy-efficient deck profiles and designs.

Modern technology in the steel floor decking roll forming machine allows it to form metal sheets into different shapes, widths, and thicknesses. Sheet feeder, adjustable guide rail, roll forming system, hydraulic cutter, control system, and run-out table make up this machine. The steel sheet enters the roll forming system after passing via the sheet feeder, which uses a hydraulic mechanism to modify the guide rail.

Multiple sets of rollers make up the roll forming system, which shapes the metal sheet into the desired pattern and contour. The run-out table then gathers the finished product after the metal sheet has been cut to the required length by the hydraulic cutter. Because the entire process is mechanized, the steel floor decks that are manufactured are of consistently high quality.

The roll forming machine's steel floor decks have significant benefits over conventional concrete decking. They save money and speed up construction since they are lightweight, simple to install, and require less concrete. The decks can be employed in a variety of structures, including commercial buildings, industries, and warehouses.

- Eave Gutter Machine

A ground-breaking piece of manufacturing machinery called the Eave Gutter Machine is intended to make seamless eaves gutters with astounding efficiency and accuracy. Because of this cutting-edge technology, it is now possible to manufacture seamless gutters that exactly fit against the roofline, revolutionizing the eaves gutter industry.

The eaves gutter manufacturing industry has altered as a result of Eave Gutter Machine's innovative technology. Aluminum, copper, and steel are just a few of the materials that can be used to make gutters. Because of its adaptability, it may be used by all sizes of roofing manufacturers and builders.

Eave Gutter Machine manufactures superior-quality eaves gutters that are free of leaks, blockages, and other flaws using specialized software and advanced manufacturing techniques. The gutters are likewise precisely cut.lengths, ensuring they fit perfectly into the eaves spaces of any roof.

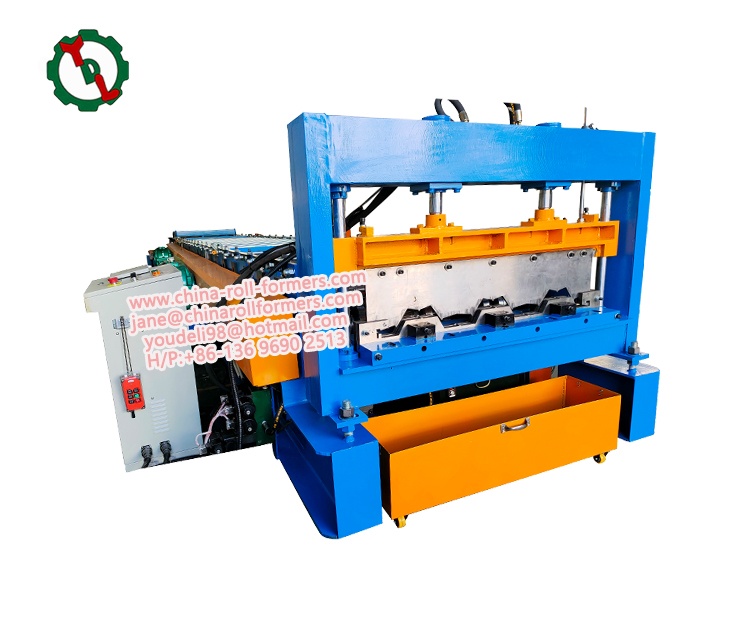

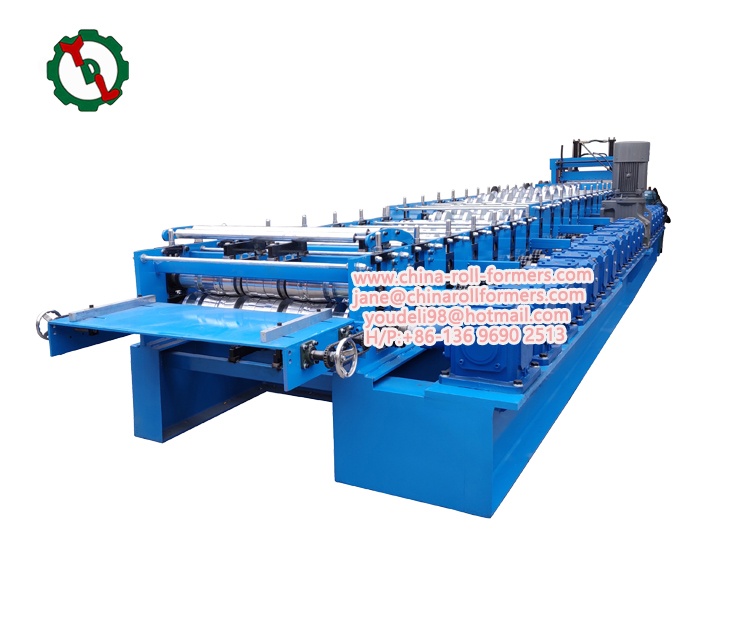

- Roofing Sheet Roll Forming Machine

This machine differs from other roll forming machines on the market thanks to a number of its features. It has a cutting system and precise rollers that guarantee flawless and exact results each and every time. Additionally, it incorporates an adjustable punching system that enables the production of trays in a variety of forms and sizes.

The Structural Liner Tray Roll Forming Machine has a high level of automation and customization options to fulfill the requirements of contemporary production lines. It is an affordable option for organizations of all sizes because it is simple to use and needs little upkeep.

For businesses in the building, roofing, or manufacturing sectors who need top-notch structural liner trays, this machine is perfect.It can produce trays with a thickness range of 0.5mm to 1.5mm and a width range of 200mm to 480mm. Customization is also available to meet specific requirements and needs.

Product Categories

Hot Articles

Choosing the right purlin roll forming machine involves considering factors such as purlin type, production speed, material capabilities, automation, precision, durability, and cost to ensure efficient, high-quality, and flexible manufacturing.

- September 19, 2024

A hydraulic uncoiler is a vital machine in manufacturing that efficiently unwinds coils of metal, ensuring precise material handling and enhancing productivity across various industries.

- November 7, 2024