All Product

Welcome to explore our comprehensive product lineup featuring cutting-edge machinery like the Double Layer Roll Forming Machine, Purlin Roll Forming Machine, Electric Seaming Machine, and more. Welcome your consultation and purchase, we look forward to providing you with a quality shopping experience!

All Product List

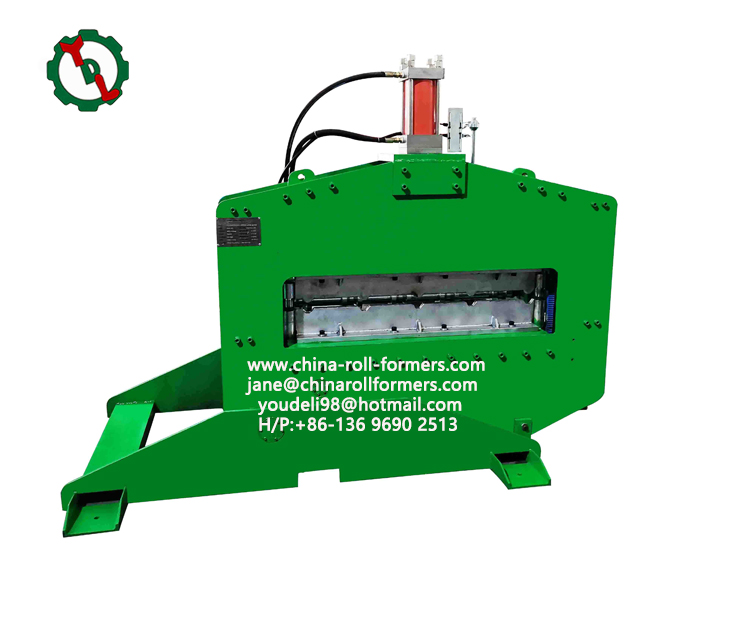

- Crimping Curving Machine

For the purpose of producing curved or arched metal constructions, the Automatic Arch Bending Curve Steel Color Crimping Rolling Curving Machine is a potent and effective tool. This cutting-edge machine's cutting-edge technology makes it simple to bend and shape steel into lovely and complicated forms, making it the ideal tool for architectural and construction projects. Heavy-duty steel sheets can be handled easily by the machine thanks to its high-capacity motor, and its automatic arch bending feature ensures accuracy and precision throughout the process. With the help of the color crimping system, you can add a new dimension to your design by producing textured and patterned surfaces for a really one-of-a-kind finish.

- Wall And Siding Panel Machine

The Wall Panel Roll Forming Machine efficiently produces high-quality metal panels for construction, offering cost-effectiveness, flexibility, faster production, consistency, ease of use, and environmental friendliness.

- Portable Standing Seam Roofing Machine

We would like to introduce our high performance, reliable, and portable standing seam machine. This machine has a solid, user-friendly design and gives great performance. Standing seam metal roofs can be produced easily and precisely with it. High-quality components and cutting-edge technology were used in the creation of our equipment to guarantee its durability and top-notch performance. Our standing seam metal roof roll forming machine may be tailored to meet your needs, giving you the most flexibility and adaptability possible. Our machine can deliver the speed and accuracy required to create roofing for residential or commercial applications. To find out more about our standing seam metal roof roll forming machine, get in touch with us right now.

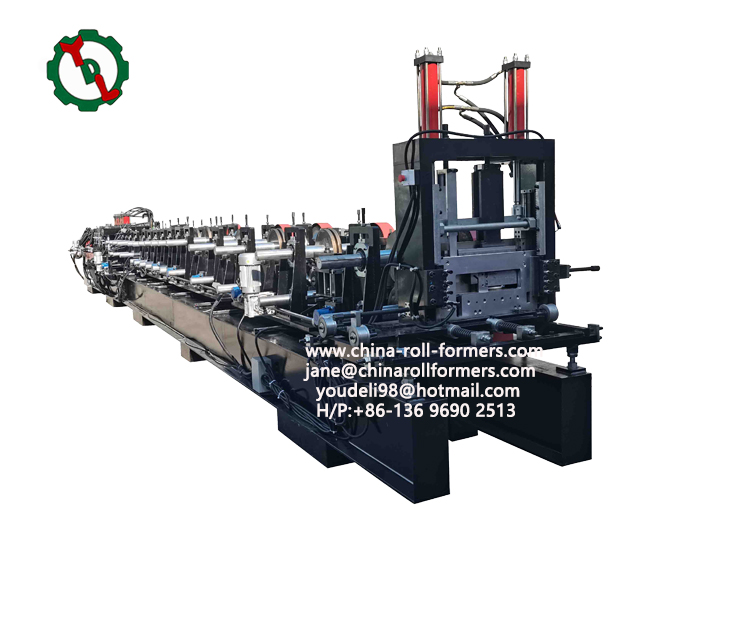

- CZ Purlin Roll Forming Machine

The Automatic Adjustment Z-Type Purlin Forming Machine is a highly efficient and precise tool that quickly produces various high-quality purlins with easy-to-use settings and minimal maintenance.

- Roofing Sheet Roll Forming Machine

A ground-breaking device that has revolutionized the global roofing business is the roofing sheet roll forming machine. The device use cutting-edge technology to create roofing sheets of the highest quality that are robust, corrosion-resistant, and available in a range of dimensions.

A highly educated and skilled group of engineers work to assure the precision and accuracy of the roofing sheet by operating the roll forming equipment for roofing sheets. This guarantees that each sheet generated is of a high level and adheres to the necessary requirements.

To enable the production of various roofing sheets, including corrugated, trapezoidal, IBR, and standing seam roofing sheets, the machine also includes a variety of different molds and equipment.The cost reductions that using a roofing sheet roll forming machine offers is one of its major advantages. The machine uses automated technologies to operate, which removes the need for a sizable crew and significantly lowers labor expenses.

The machine's operation speed is an additional benefit. It can quickly generate large quantities of roofing sheets, guaranteeing that deadlines are completed on time.

The roofing sheet roll forming machine is also eco-friendly because it generates less trash during production, minimizing its negative effects on the environment.

- Crimping Curving Machine

The crimping curving machine is revolutionary for the aluminum sector. It offers a quick, effective, and precise method for shaping aluminum into various shapes, ensuring that producers create high-quality goods that satisfy customers' needs. The machine is a great investment for any aluminum production company because of its adaptability, simplicity of use, and capacity to produce products with different thicknesses.

Product Categories

Hot Articles

C Purlin machines are essential in modern construction, offering efficiency, cost-effectiveness, and quality in producing C-shaped purlins for structural support.

- May 8, 2024

The article explores how a rolling shutter roll forming machine operates and outlines the basic steps involved in the roll forming process, highlighting its significance in manufacturing high-quality rolling shutters.

- April 5, 2024