All Product

Welcome to explore our comprehensive product lineup featuring cutting-edge machinery like the Double Layer Roll Forming Machine, Purlin Roll Forming Machine, Electric Seaming Machine, and more. Welcome your consultation and purchase, we look forward to providing you with a quality shopping experience!

All Product List

- Profile Roll Forming Machine

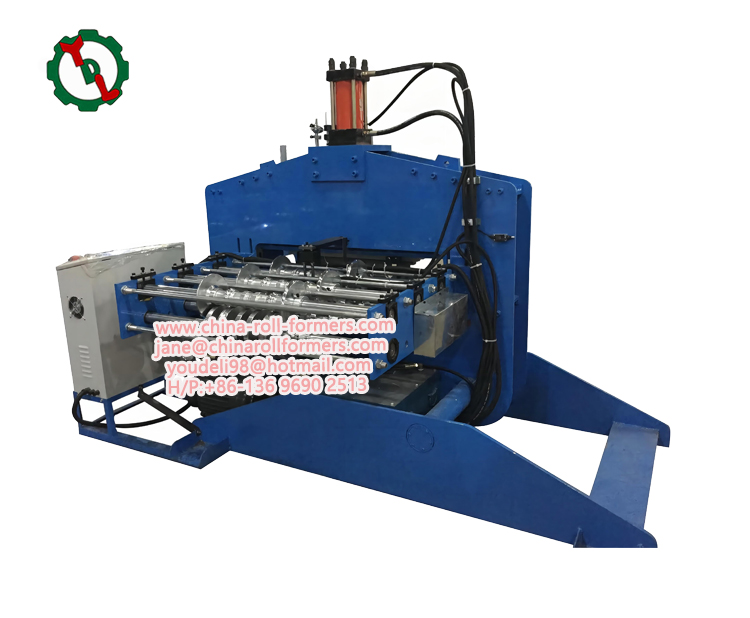

Double Profiles Roll Forming Machine is a versatile piece of equipment that aims to revolutionize the metal forming industry. This machine is designed to efficiently produce two different profiles simultaneously, saving time and increasing productivity for manufacturers.

One of the key advantages of the Double Profiles Roll Forming Machine is its ability to work with various materials, including steel, aluminum, and other metals. This versatility allows manufacturers to create a wide range of products, from roofing panels to vehicle components, with ease.

The machine’s design includes multiple stations, each equipped with rollers and tools that shape the metal into the desired profiles. The dual-profile capability means that manufacturers can produce different types of profiles on the same machine, eliminating the need for multiple machines for different products.

In addition to its efficiency, the Double Profiles Roll Forming Machine also offers precision and consistency in the production process. The rollers and tools are specially designed to meet the exact specifications of the profiles, ensuring uniformity and high-quality results every time.

Another notable feature of this machine is its user-friendly interface, making it easy for operators to set up and run production. With simple controls and programmable settings, manufacturers can quickly switch between profiles and make adjustments as needed.

The Double Profiles Roll Forming Machine is ideal for manufacturers looking to streamline their production process and increase output. By investing in this advanced equipment, companies can reduce lead times, minimize waste, and improve overall efficiency in their metal forming operations.

Overall, the Double Profiles Roll Forming Machine represents a significant advancement in metal forming technology. Its dual-profile capabilities, versatility, precision, and user-friendly design make it a valuable asset for manufacturers seeking to stay competitive in today’s fast-paced market.

In conclusion, the Double Profiles Roll Forming Machine is a game-changer for the metal forming industry. With its innovative design and advanced features, this machine offers a cost-effective solution for producing high-quality profiles efficiently and accurately. Manufacturers who invest in this equipment can expect to see a significant improvement in their production capabilities and overall business performance.

- Storage Rack Roll Forming Machine

Storage rack column roll forming machine with pre-punching & fly cutting is a cutting-edge technology used in the manufacturing of storage rack columns. This machine combines the roll forming process with pre-punching and fly cutting functions, allowing for high efficiency and precision in the production of storage racks.

The roll forming process involves feeding a strip of metal through a series of rollers to gradually shape it into the desired profile. Pre-punching refers to the process of creating holes or slots in the metal strip before it is formed, which is essential for attaching components or accessories to the storage racks. Fly cutting involves cutting the metal strip into individual pieces at high speeds, ensuring accuracy and speed in the manufacturing process.

By integrating these three functions into one machine, manufacturers can streamline the production process and reduce the need for manual labor. This not only increases efficiency but also ensures consistent quality in the finished products. Storage rack columns made using this technology are highly durable and reliable, making them ideal for storing heavy items in warehouses or distribution centers.

In addition to its efficiency and precision, the storage rack column roll forming machine with pre-punching & fly cutting also offers versatility. Manufacturers can easily adjust the machine settings to produce different sizes and shapes of storage rack columns, meeting the diverse needs of their customers.

Overall, this cutting-edge technology is revolutionizing the manufacturing industry by improving productivity, quality, and versatility in the production of storage rack columns. Companies that invest in this technology can stay ahead of the competition and meet the growing demand for high-quality storage solutions.

- Storage Rack Roll Forming Machine

When it comes to efficiently storing and organizing products in warehouses, storage racks play a crucial role. And the key to producing strong and durable storage racks lies in the quality of the roll forming machines used in the manufacturing process.

One popular type of roll forming machine used for producing storage racks is the P Girder Roll Forming Machine with Fly Cutting. This advanced machine is designed to efficiently and accurately produce P girder profiles that are commonly used in the construction of storage racks.

The P Girder Roll Forming Machine with Fly Cutting is equipped with cutting-edge technology that enables it to form P girder profiles with precision and speed. The fly cutting feature allows for continuous cutting of the profiles, ensuring a smooth and efficient production process.

The machine is also capable of forming P girder profiles with different dimensions and thicknesses, making it versatile and suitable for various storage rack applications. Whether you need to produce heavy-duty racks for storing large and heavy items or lighter racks for smaller products, this machine can handle it all.

In addition to its exceptional forming capabilities, the P Girder Roll Forming Machine with Fly Cutting is also designed for ease of operation and maintenance. Its user-friendly interface and intuitive controls make it easy for operators to set up and run the machine, while its sturdy construction ensures long-term durability and reliability.

By investing in a high-quality P Girder Roll Forming Machine with Fly Cutting, manufacturers can produce storage racks that are not only structurally sound and durable but also cost-effective and efficient. With the ability to produce racks of various sizes and configurations, this machine offers the versatility and performance needed to meet the demands of modern warehouse storage solutions.

In conclusion, the P Girder Roll Forming Machine with Fly Cutting is an indispensable tool for manufacturers looking to produce strong and reliable storage racks. Its advanced technology, precision forming capabilities, and ease of operation make it a valuable asset for any warehouse or storage rack production facility.

- Profile Roll Forming Machine

The Clip Double Profiles Roll Forming Machine is a specialized industrial system designed to fabricate metal profiles with interlocking or clipped configurations in a single production pass. Here's a detailed breakdown of its features, applications, and advantages:

Key Features

- Dual-Profile Forming:

- Simultaneously shapes two interconnected metal profiles (e.g., C-channels, U-shapes, or custom sections) using synchronized roller sets.

- Ideal for producing components like roofing panels, wall cladding, or structural framing with integrated clips for assembly.

- Clipping Mechanism:

- Incorporates punching or bending stations to create interlocking tabs, slots, or hooks on the profiles.

- Enables quick assembly without additional fasteners (e.g., for modular buildings or HVAC ducts).

- High Precision:

- Adjustable rollers and computerized controls ensure consistent thickness, angles, and clip placement.

- Supports materials like galvanized steel, aluminum, or pre-painted coils (0.3–1.5 mm thickness).

- Automation:

- Integrated decoiler, leveler, and cut-off press for continuous, high-speed production.

- Optional features: automatic stacking, labeling, or quality inspection systems.

- Standing Seam Curving Machine

The Automatic Adjusted Smooth Curving Machine is a specialized industrial system designed to create precise, continuous curves in materials like metal, plastic, composites, or wood. Here's a structured overview of its key features, applications, and technology:

1、Core Functionality Automation: Operates with minimal human intervention, using programmed instructions or AI-driven algorithms to adjust parameters in real-time.

2、Adjustability: Dynamic Calibration: Sensors and feedback systems automatically modify force, speed, or temperature to maintain curve quality.

Material Adaptation: Adjusts for material thickness, elasticity, or hardness (e.g., aluminum vs. carbon fiber).

3、Smooth Curving: Seamless Results: Eliminates joints or imperfections via processes like hydroforming, stretch forming, or robotic grinding.

Precision Control: Uses CNC (Computer Numerical Control) or robotic arms for micro-adjustments, ensuring consistent curvature.

- Roofing Sheet Roll Forming Machine

When it comes to efficient and high-quality roll forming machines, the Mini Rib Panel Roll Forming Machine stands out as a top choice. This machine is specially designed to create ribbed panels with precision and speed, making it ideal for a wide range of applications in the construction industry.

One of the key features of the Mini Rib Panel Roll Forming Machine is its compact size, which allows for easy transportation and installation on job sites. Despite its small footprint, this machine is powerful and capable of producing ribbed panels with consistent quality and accuracy.

The Mini Rib Panel Roll Forming Machine is also highly customizable, allowing users to adjust the settings to create panels of different sizes and shapes. This versatility makes it a versatile tool for various construction projects, from roofing and cladding to fencing and decking.

In addition to its impressive performance, the Mini Rib Panel Roll Forming Machine is also easy to operate and maintain. With user-friendly controls and a durable construction, this machine is built to last and withstand the rigors of daily use on job sites.

Product Categories

Hot Articles

A shutter door machine is an automated system that efficiently manufactures rolling shutter doors by shaping, cutting, punching, and assembling slats from materials like steel, aluminum, or PVC, offering high-quality, customizable, and cost-effective solutions for various applications.

- November 27, 2024

This article provides an in-depth look into the operation of crimping curving machines, covering their key components, working principles, applications, maintenance, and the latest technological advancements.

- June 28, 2024